Liquid metal-polymer composite soft actuator and preparation method thereof

A software driver, liquid metal technology, applied in the direction of manufacturing tools, manipulators, etc., can solve the problems affecting the overall performance of the driver, the irregular shape of the droplet, the anisotropy of the performance distribution, etc., and achieve excellent light/heat/electricity-mechanical energy conversion ability, the effect of excellent humidity response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

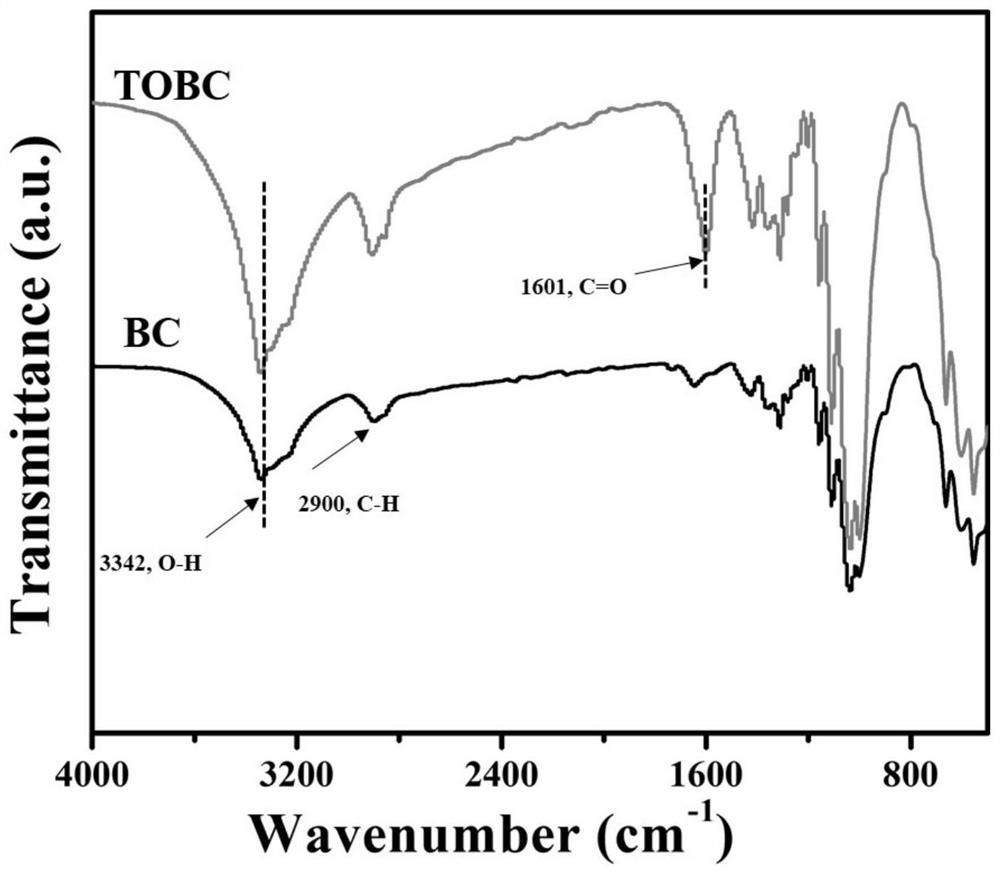

[0048] Take 10mL of the above-mentioned liquid metal-based functional coating and coat it on the surface of hydrophobic polytetrafluoroethylene (PTFE) substrate. At room temperature, through evaporation and sintering, combined with the density gradient relationship, an organic / inorganic coating with precise and controllable thickness can be obtained. Janus self-supporting smart film materials, as Figure 6 shown. It can be seen from the figure that the upper layer is off-white and combined with the scanning electron microscope, it can be seen that it is mainly composed of nanocellulose, and the lower layer is silver. Combined with the scanning electron microscope, it can be seen that it is mainly composed of liquid metal nanoparticles with uniform size and close connection, and There is a small amount of nanocellulose distributed around the particles. Through the capillary action of nanocellulose, the liquid metal oxide layer is destroyed, and the stable conductivity of the s...

Embodiment 2

[0050] The liquid metal-based functional coating prepared above is selectively coated on the surface of a polymer shape memory polymer (SMP) substrate (such as polystyrene, referred to as PS), and under the action of non-focused near-infrared light, to achieve Three-dimensional self-folding of different patterns, turning off the non-focused near-infrared light, the self-folding pattern remains unchanged.

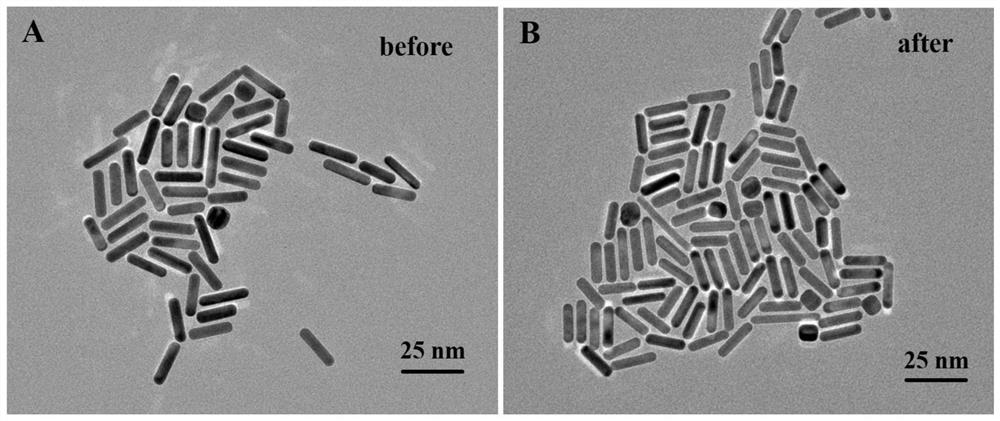

[0051] (1) V-shaped pattern

[0052] Such as Figure 11 As mentioned above, 50 μL of liquid metal-based functional paint is selectively coated on the middle part of the 25 mm × 10 mm × 0.2 mm SMP substrate, as a hinge, its length and width are 10 mm × 1.2 mm, after natural drying, through non-focusing near Infrared light effect, due to the excellent photothermal and thermal conductivity of EGaIn and GNRs-COOH in the coating area, the pre-stretched SMP in the coating area is heated to the shape recovery temperature (such as Tg), the reversible phase softens and the stationar...

Embodiment 3

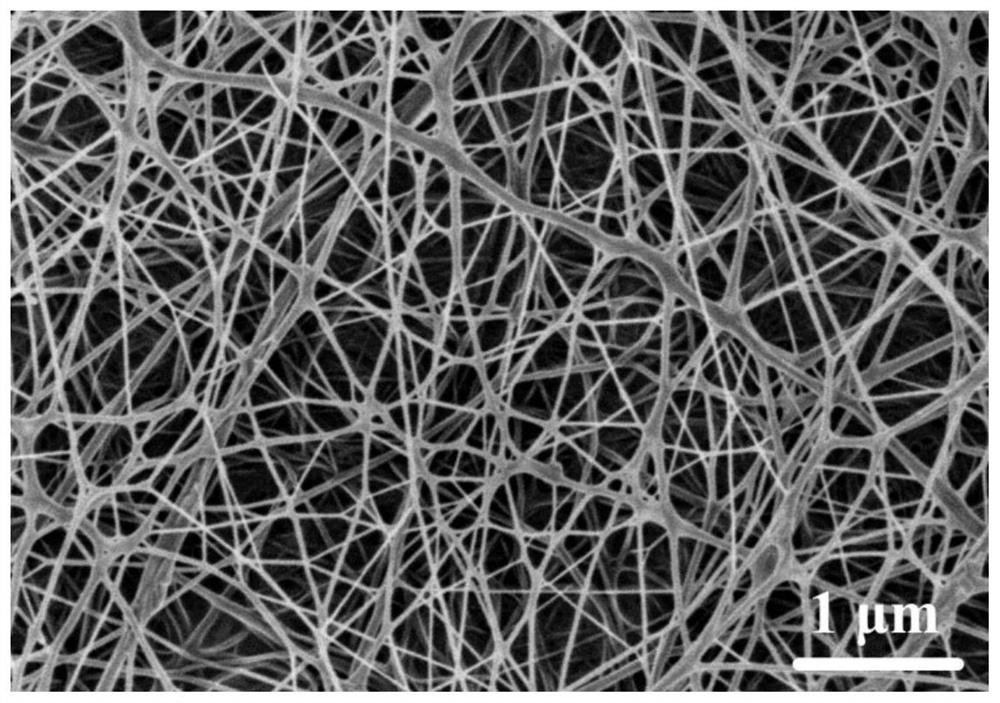

[0060] Such as Figure 15 As described above, the liquid metal-based functional coating prepared above is coated on a liquid crystal elastomer (LCE) (15mm×3.0mm×23μm) substrate, and after natural drying, the surface layer is liquid due to the action of 808nm near-infrared light. The excellent photothermal and thermal conductivity of metal and gold nanorods will induce the anisotropic to isotropic phase transition of the liquid crystal elastomer, so that the coated liquid crystal film will undergo a phenomenon from initial bending to flatness and then to reverse bending. Infrared light will cause the liquid crystal film in the coating area to change from isotropic to anisotropic phase, causing the coated liquid crystal film to return to its original state. By repeating this process, hundreds of reversible bends of the coated liquid crystal film can be achieved, such as Figure 16 shown. At the same time, due to the high capillary force generated by the modified BC during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com