Automatic sludge cleaning and drying device for hydraulic engineering

An automatic cleaning and water conservancy engineering technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc. Firmness and other issues, to achieve the effect of convenient and quick removal and recycling, high degree of automation, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

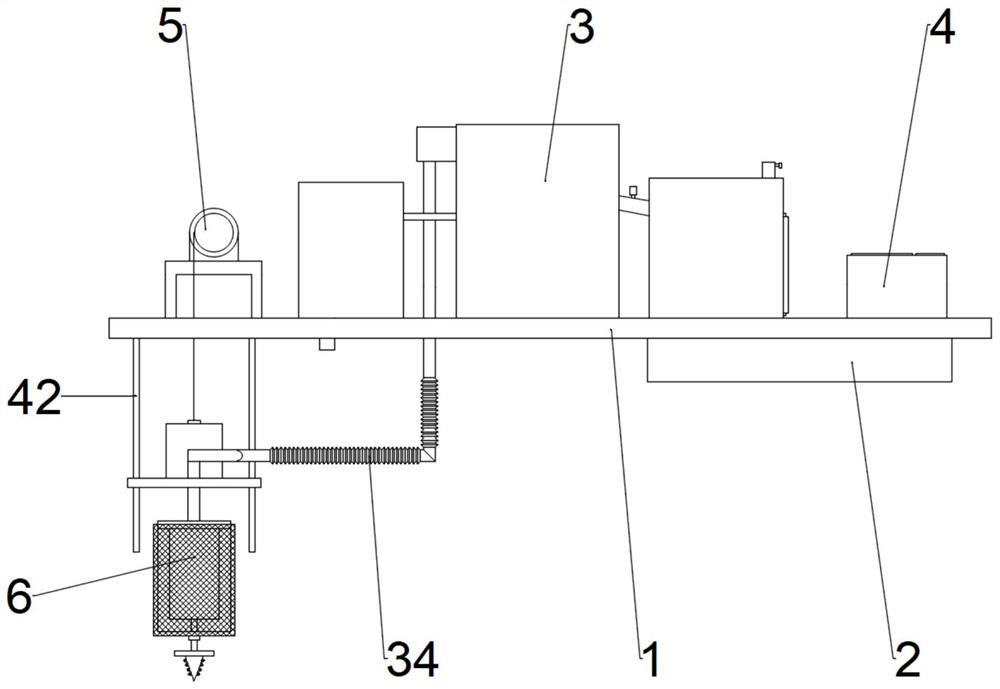

[0024] An automatic sludge cleaning and drying device for water conservancy projects, comprising such figure 1 As shown in the bottom plate 1, one side of the bottom plate 1 is connected with a mounting plate 2, and the middle part of the other side of the bottom plate 1 is connected with a sludge treatment mechanism 3, and the two sides of the sludge treatment mechanism 3 are respectively provided with There are hoisting mechanism 5 and control box 4, and described hoisting mechanism 5 and control box 4 are all installed on the other side board surface of base plate 1, and described base plate 1 is provided with mud suction mechanism 6 far away from the side of hoisting mechanism 5, The mud suction mechanism 6 is connected with the lifting mechanism 5 through a lifting rope.

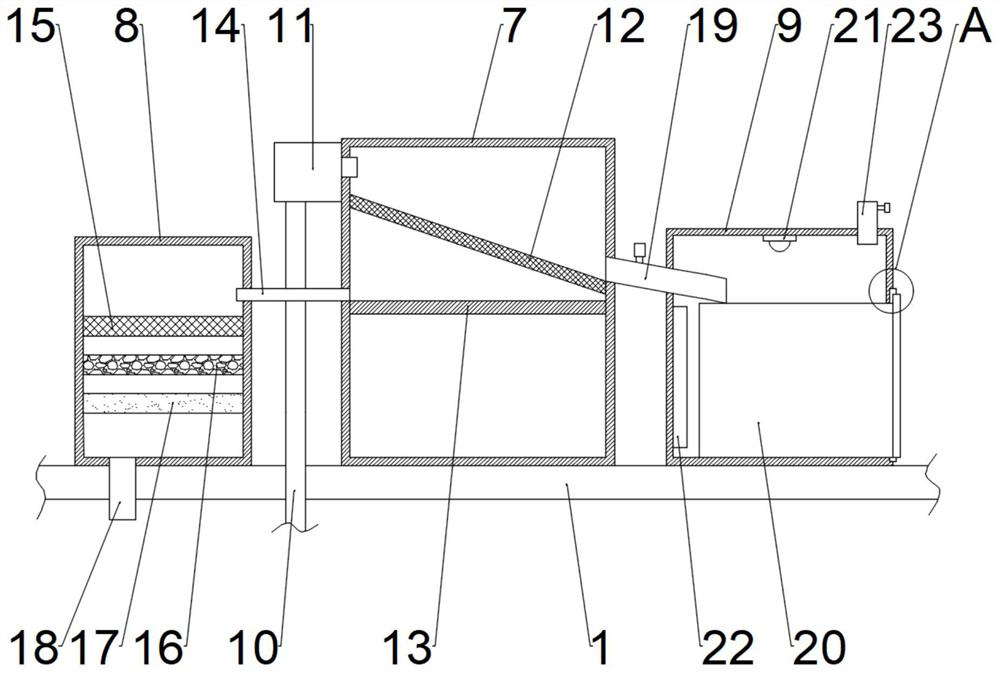

[0025] The sludge treatment mechanism 3 includes such as figure 2 The dehydration box 7 shown and the filter box 8 and the collection box 9 respectively arranged on both sides of the dehydration box 7...

Embodiment 2

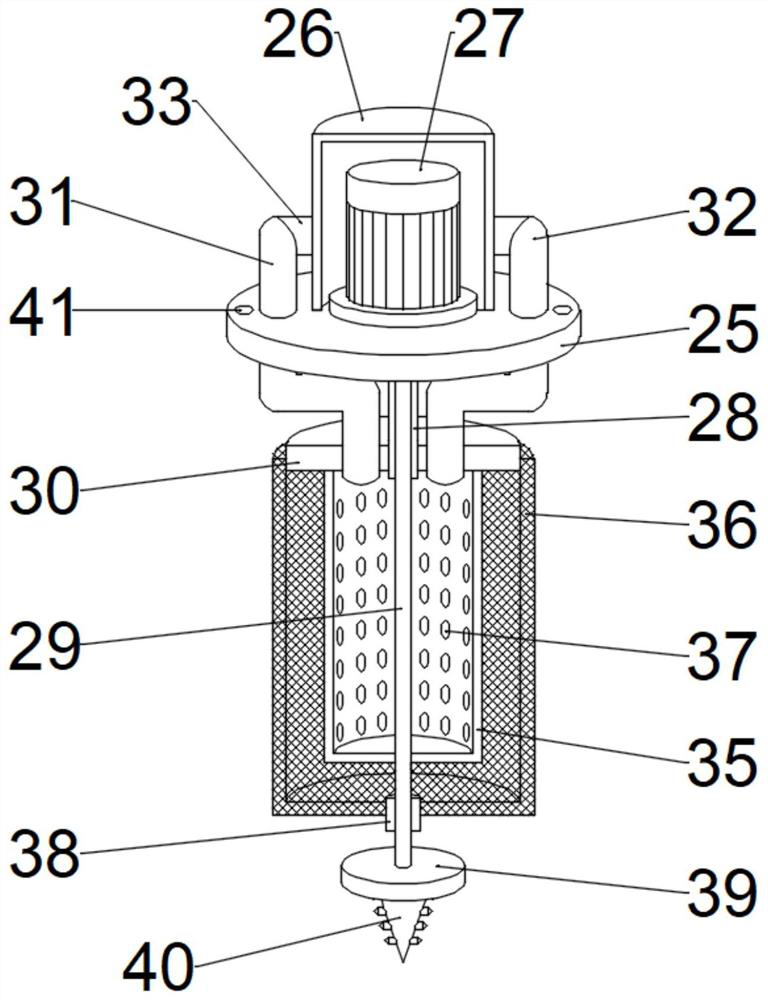

[0030] On the basis of Embodiment 1, although the sludge can be well pulverized and inhaled for subsequent processing, the movable plate 25 is prone to shaking during the up and down movement, which affects the stability of the mud suction mechanism 6 properties, therefore, the movable plate 25 is opened as figure 1 The two positioning holes 41 shown are symmetrically distributed along the central axis of the height direction of the movable plate 25 , and positioning rods 42 are arranged in the positioning holes 41 , and one end of the positioning rods 42 is fixedly connected to the side end of the bottom plate 1 .

[0031] The length of the positioning rod 42 matches the length of the hoisting rope. Through the cooperation of the positioning rod 42 and the positioning hole 41, the mud suction mechanism 6 can maintain the stability in the horizontal direction when moving, thereby ensuring the operation of the overall device. Status remains stable.

[0032] To sum up, the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com