Method for preparing methoxyamine hydrochloride by adopting microreactor

A technology of methoxyamine hydrochloride and microreactor, which is applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve the problem of methoxyamine hydrochloride collection The efficiency and purity are not very high, so as to achieve the effect of improving product selectivity, reducing by-products and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of embodiment 1 methoxyamine hydrochloride

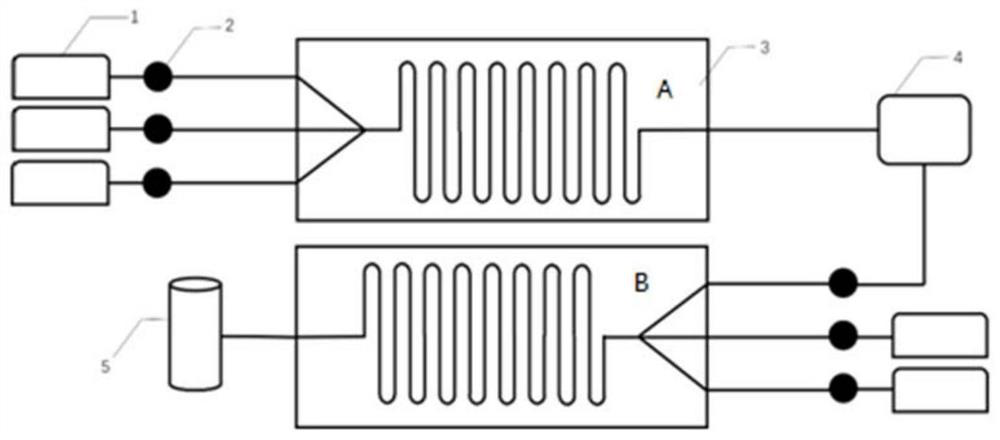

[0029] according to figure 1 The connection method is used to build a microreactor and carry out the reaction:

[0030] (1) Weigh 10g of hydroxylamine hydrochloride and add it to 100mL of water and stir to obtain hydroxylamine hydrochloride solution, add 20g of ethyl acetate and 60g of 20% sodium hydroxide solution into the material tank respectively, and then pump it into the microchannel through a constant flow pump In the reaction module A, the reaction obtains solution a;

[0031] (2) 190 g of solution a, 10 g of dimethyl sulfate and 60 g of 20% sodium hydroxide solution were pumped into the microchannel reaction module B to react to obtain solution b;

[0032] (3) Take solution b out of the collection tank, add hydrochloric acid (hydrolysis step), and reflux at 65°C for 1 h; then distill under atmospheric pressure at 65°C (distillation step), and cool the solution to 40°C; add sodium hydroxide s...

Embodiment 2

[0033] The preparation method of embodiment 2 methoxyamine hydrochloride

[0034] (1) Weigh 500g of hydroxylamine hydrochloride and add it to 500mL of water and stir to obtain hydroxylamine hydrochloride solution, add 1000g of ethyl acetate and 3000g of 10% sodium hydroxide solution to the material tank respectively, and then pump it into the microchannel through a constant flow pump In the reaction module A, the reaction obtains solution a;

[0035] (2) respectively pump 5000g of solution a, 1000g of dimethyl sulfate and 3000g of 10% sodium hydroxide solution into the microchannel reaction module B to react to obtain solution b;

[0036] (3) Take out 9000g of solution b in the collection tank, add hydrochloric acid (hydrolysis step), and reflux at 65°C for 1 h; then distill under atmospheric pressure at 65°C (distillation step), and cool the solution with circulating water and ice brine to 40°C; add sodium hydroxide solution to make the pH of the solution reach about 7.0 (ne...

Embodiment 3

[0037] The preparation method of embodiment 3 methoxyamine hydrochloride

[0038] (1) Weigh 250g of hydroxylamine hydrochloride and add it into 500 mL of water and stir to obtain hydroxylamine hydrochloride solution, add 500g of ethyl acetate and 1000g of 10% sodium hydroxide solution into the material tank respectively, and then pump it into the micro In channel reaction module A, the reaction obtains solution a;

[0039](2) Pump 22500g of solution a, 500g of dimethyl sulfate and 1000g of 31% sodium hydroxide solution into the microchannel reaction module B to react to obtain solution b;

[0040] (3) Take out 3750g of solution b in the collection tank, add hydrochloric acid (hydrolysis step), and reflux at 65°C for 1 h; then distill at 65°C under atmospheric pressure (distillation step), and cool the solution with circulating water and ice brine to 40°C; add sodium hydroxide solution to make the pH of the solution reach about 7.0 (neutralization step), stir for 10 minutes; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com