Preparation method of antibacterial preservative film loaded with nanoscale essential oil

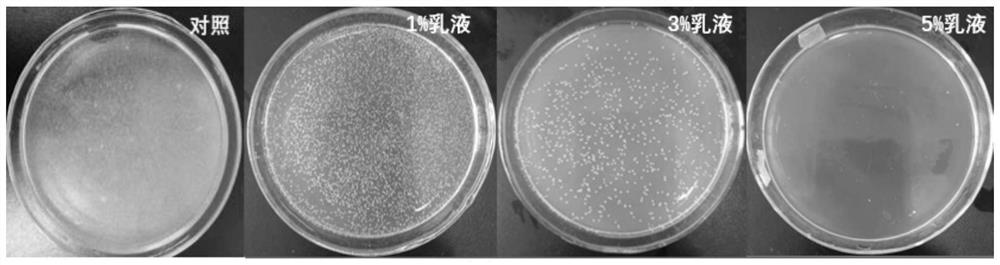

A nano-scale, essential oil technology, applied in the field of food preservation, can solve the problems of unsatisfactory antibacterial effect, low content of essential oil in film, limited essential oil amount, etc., and achieves the effects of excellent antibacterial performance, simple preparation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an antibacterial preservative film loaded with nanoscale essential oils, comprising the following steps:

[0033] (1) Preparation of nanoscale oregano essential oil emulsion:

[0034] Weigh an appropriate amount of xanthan gum, add it to 40°C water and stir at a speed of 150rpm until dissolved, and make a xanthan gum solution with a mass concentration of 2%;

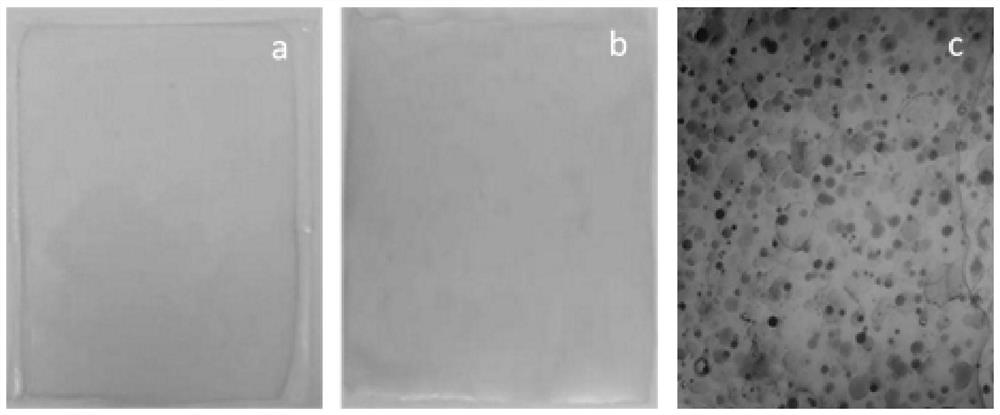

[0035] Add β-cyclodextrin into water, heat and dissolve at 60°C to obtain a β-cyclodextrin solution with a volume content of 2%, and add oregano essential oil to the β-cyclodextrin solution, wherein the amount of oregano essential oil added is β - 1.5 times the volume of the cyclodextrin solution, whipped at a high speed of 12000rpm for 1min to form a semi-fluid emulsion;

[0036] Add the above-mentioned xanthan gum solution to the obtained semi-fluid emulsion, so that the amount of xanthan gum added is 0.2% of the volume of the semi-fluid emulsion, and whip it again at a high speed of 1200...

Embodiment 2

[0043] A method for preparing an antibacterial preservative film loaded with nanoscale essential oils, comprising the following steps:

[0044] (1) Preparation of nanoscale citral emulsion:

[0045] Weigh an appropriate amount of xanthan gum, add it to 40°C water and stir until dissolved at 150rpm to make a xanthan gum solution with a mass concentration of 4%;

[0046] Add β-cyclodextrin into water, heat to 60°C to dissolve to obtain a β-cyclodextrin solution with a volume content of 3%, add citral essential oil to the β-cyclodextrin solution, and the amount of citral essential oil added is β - 1.8 times the volume of the cyclodextrin solution, whipped at a high speed of 12000 rpm for 3 minutes to form a semi-fluid emulsion;

[0047] Add the above-mentioned xanthan gum solution to the obtained semi-fluid emulsion, so that the amount of xanthan gum added is 0.4% of the volume of the semi-fluid emulsion, whipped at a high speed of 12000rpm for 1min, further increase the stabili...

Embodiment 3

[0054] A method for preparing an antibacterial preservative film loaded with nanoscale essential oils, comprising the following steps:

[0055] (1) Preparation of nanoscale citral emulsion:

[0056] Weigh an appropriate amount of xanthan gum, add it to 40°C water and stir at a speed of 150rpm until dissolved, and make a xanthan gum solution with a mass concentration of 4%;

[0057] Add β-cyclodextrin into water, heat to 60°C to dissolve to obtain a β-cyclodextrin solution with a volume content of 3%, add 1.5 times the volume of citral essential oil to the β-cyclodextrin solution, and run at a high speed of 12000rpm Whip for 3 minutes to form a semifluid nanoscale citral emulsion;

[0058] Add above-mentioned xanthan gum solution in gained semi-fluid state emulsion, make xanthan gum addition be 0.2% of semi-fluid state emulsion volume, 12000rpm high-speed whipping 1min, further increase emulsion stability, obtain the citral emulsion of nanoscale, spare.

[0059] (2) prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com