Patternable liquid crystal film based on spiropyran derivative molecular switch and preparation method and application of liquid crystal film

A technology of spiropyran derivatives and molecular switches, applied in chemical instruments and methods, liquid crystal materials, luminescent materials, etc., can solve problems such as easy oxidation and decomposition, fast aging, general patterning effect, etc., to improve stability and use Longevity, improved overall effect, good patterning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

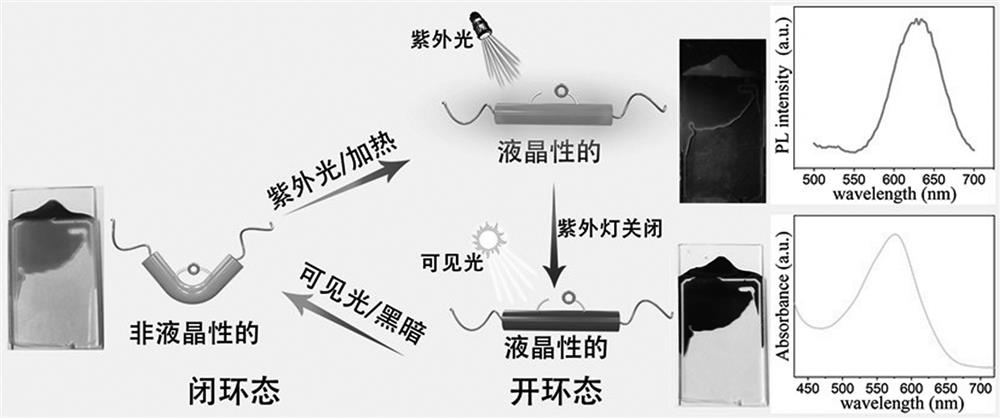

[0046] The preparation method of embodiment 1~7 spiropyran derivative

[0047] Examples 1 to 7 are respectively a preparation method of a spiropyran derivative. The spiropyran derivative is obtained by taking 10 mol of 1',3',3'-trimethyl-6-nitrospiro[benzo Pyran-2,2'-indoline]-5',8-diol (referred to as compound 1) and 20mol of benzoic acid (referred to as compound 2) substituted with alkoxy groups and derivatives thereof at the para-position 20mol of dicyclohexylcarbodiimide is used as a dehydrating agent, and 1mol of 4-dimethylaminopyridine is used as a catalyst for the esterification reaction. The chemical reaction formula of the specific esterification reaction is as follows:

[0048]

[0049] Among them, R is n is an integer among 2-18.

[0050] The difference in the preparation methods of the spiropyran derivatives in Examples 1 to 7 is only that the difference in compound 2 and the adjustment of reaction parameters such as the esterification reaction time known to ...

Embodiment 8~14

[0059] Examples 8-14 Preparation method of patternable liquid crystal film based on spiropyran derivative molecular switch

[0060] Examples 8 to 14 are respectively a method for preparing a patternable liquid crystal film based on a molecular switch of a spiropyran derivative. ) and the photoinitiator are heated to 80-100°C to melt, stir and mix well, add to the liquid crystal cell, raise the temperature to the clearing point, observe the phase change of the liquid crystal with a polarizing microscope, determine the crystallization point of the liquid crystal mixture, and cool down to the crystallization point +2℃~clearing point -2℃, keep warm, then place it at 5~100mW / cm 2 Irradiate under visible light to make it polymerized and solidified for 1-5 hours. After the polymerization and solidification is completed, the liquid crystal cell is removed, and the corresponding patternable liquid crystal film based on the molecular switch of the spiropyran derivative is obtained, whic...

Embodiment 15

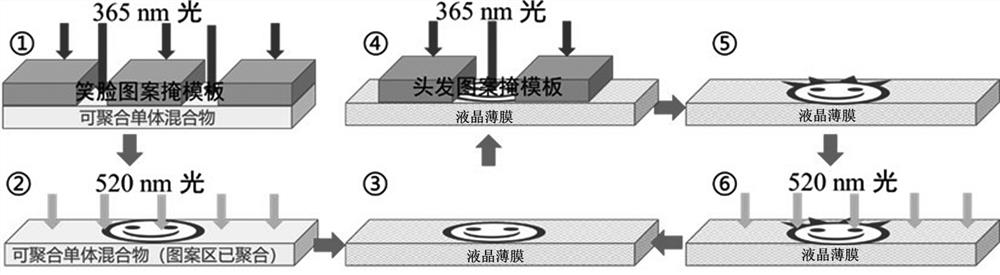

[0069] Example 15 A patterning method of a patternable liquid crystal film based on a spiropyran derivative molecular switch

[0070] This embodiment is a method for patterning a patternable liquid crystal film based on a molecular switch of a spiropyran derivative. Heat the initiator to 90°C to melt, stir and mix well, add it to the liquid crystal cell, raise the temperature to the clearing point of 70°C, observe the phase change of the liquid crystal with a polarizing microscope, and confirm that the crystallization point of the liquid crystal mixture is 43°C, and cool down to 48°C Insulation, the optical mask with the initial pattern (i.e. the mask of the smiley face pattern) is covered on the upper surface of the liquid crystal cell after insulation, and the temperature is controlled by 10mW / cm 2 365nm photopolymerization curing (first time) for 1.5h, remove the optical mask with the initial pattern, and then 10mW / cm 2 520nm visible light polymerization curing (second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com