Temperature rising system and method for controlling self-starting of deaerator based on data model

A data model, deaerator technology, applied in control systems, chemical instruments and methods, auxiliary controllers with auxiliary heating devices, etc., can solve the problems of low heating efficiency, water impact, long time consumption, etc., to reduce fuel consumption , good deoxygenation effect, reduce the effect of starting time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

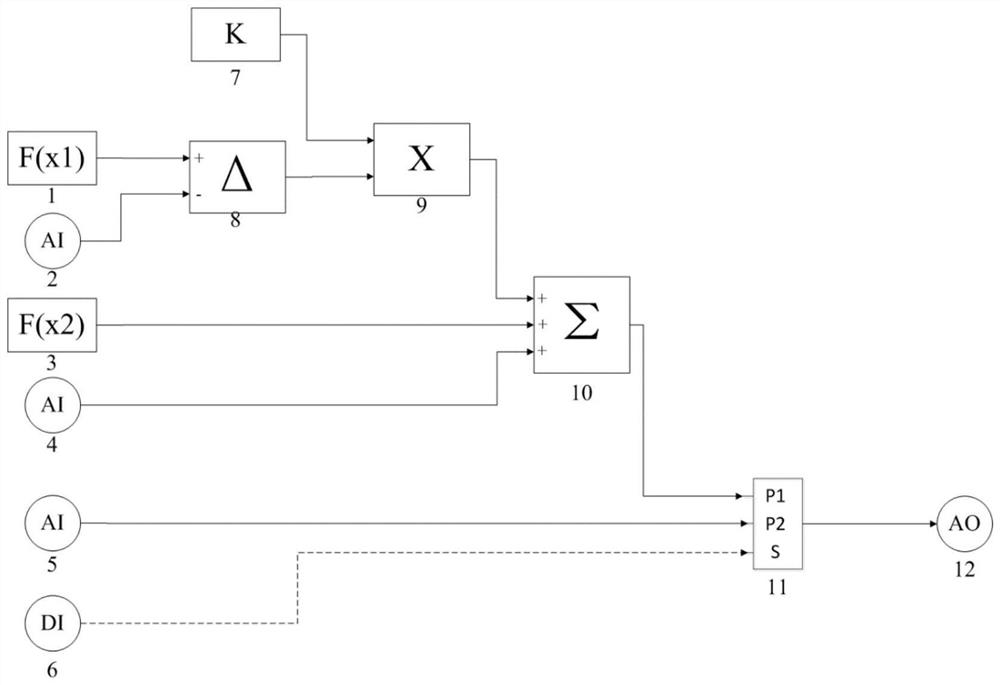

[0024] refer to figure 1 , a kind of method based on data model of the present invention controls deaerator system self-starting heating technology, comprises deaerator temperature temperature rise expert function curve F (x1) module 1, deaerator temperature AI module 2, deaerator Steam heating control valve instruction expert function curve F(x2) module 3, time-based open-loop control instruction module 4, deaerator steam heating control valve feedback module 5, input automatic control deaerator heating module 6, coefficient k module 7, Subtraction module 8, multiplication module 9, addition module 10, switching module 11, deaerator steam heating control valve instruction output module 12.

[0025] By using Matlab (R2019b) to summarize and analyze the data of multiple manual deaerator heating and starting processes, the specific point value ranges of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com