System and method for machining nanoelectrode on material substrate through femtosecond laser

A femtosecond laser and nano-electrode technology, applied in the field of femtosecond laser applications, can solve problems affecting the performance of micro-electrodes, short-circuit faults, etc., and achieve the effects of reducing the risk of short-circuit faults, high positioning accuracy, and high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

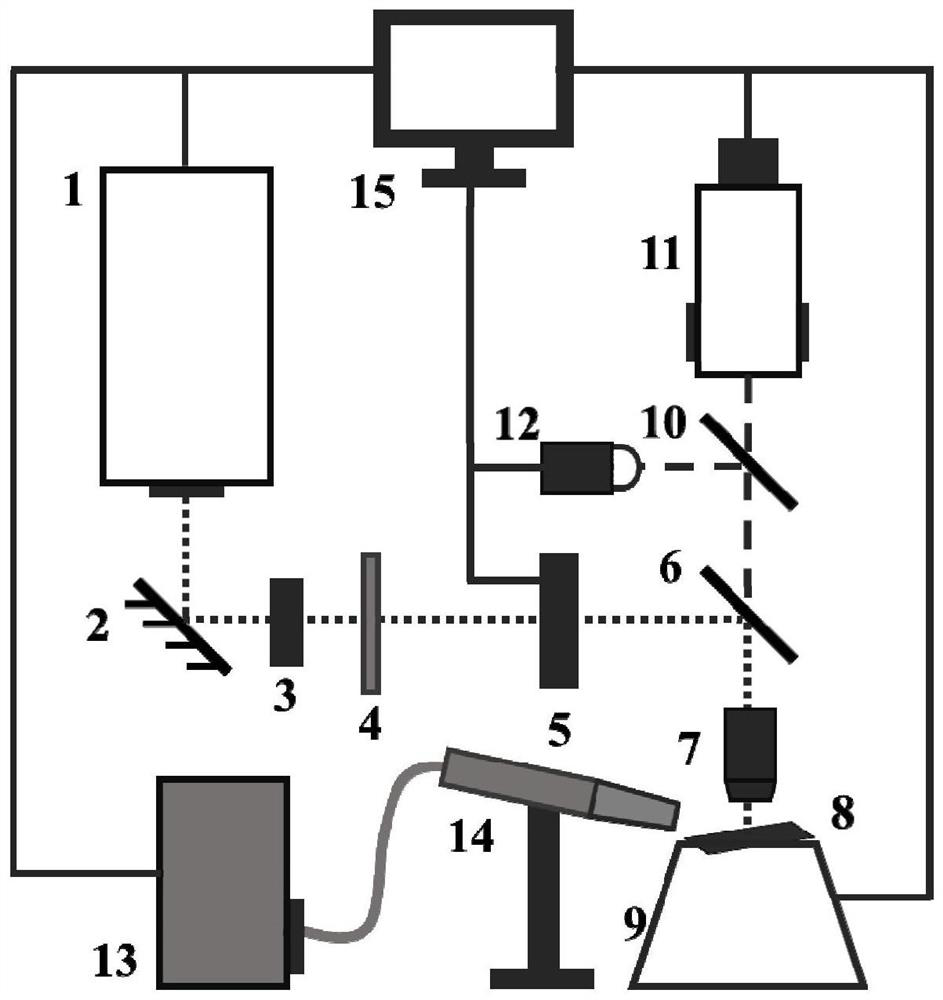

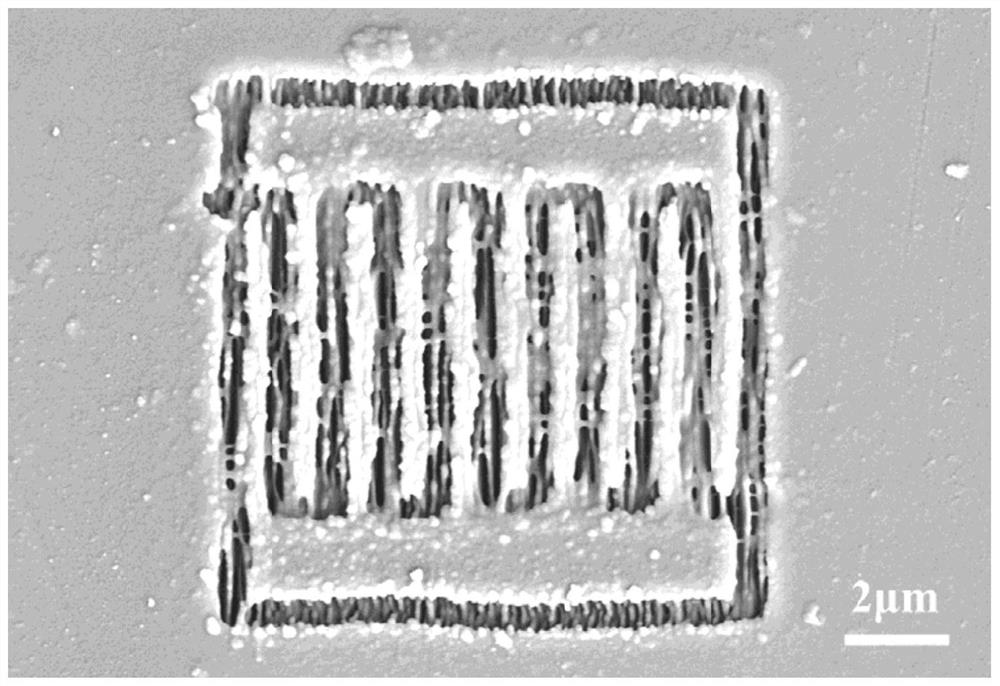

[0028] Fabrication of nanometer interdigitated electrodes on two-dimensional material substrates using femtosecond laser. Turn on the femtosecond laser 1, adjust the aperture 2 so that the spot diameter is 4 mm, adjust the position of the telephoto high-power objective lens 7 so that the focus falls near the surface of the high-precision three-dimensional motion platform 9, close the electronically controlled shutter 5, turn on the CCD 11 and the lighting lamp 12, Adjust the height of the high-precision three-dimensional motion platform 9 and the CCD 11 to make the image clear, adjust the attenuation plate 4 to make the power of the femtosecond laser 5-10 μW, adjust the height of the high-precision three-dimensional motion platform 9 to focus the femtosecond laser on the two-dimensional material sample 8 , turn on the air pump 13, align the blowing port 14 with the two-dimensional material sample 8, adjust the air pressure of the air pump 13 to 20 kPa, so that a uniform and sta...

Embodiment 2

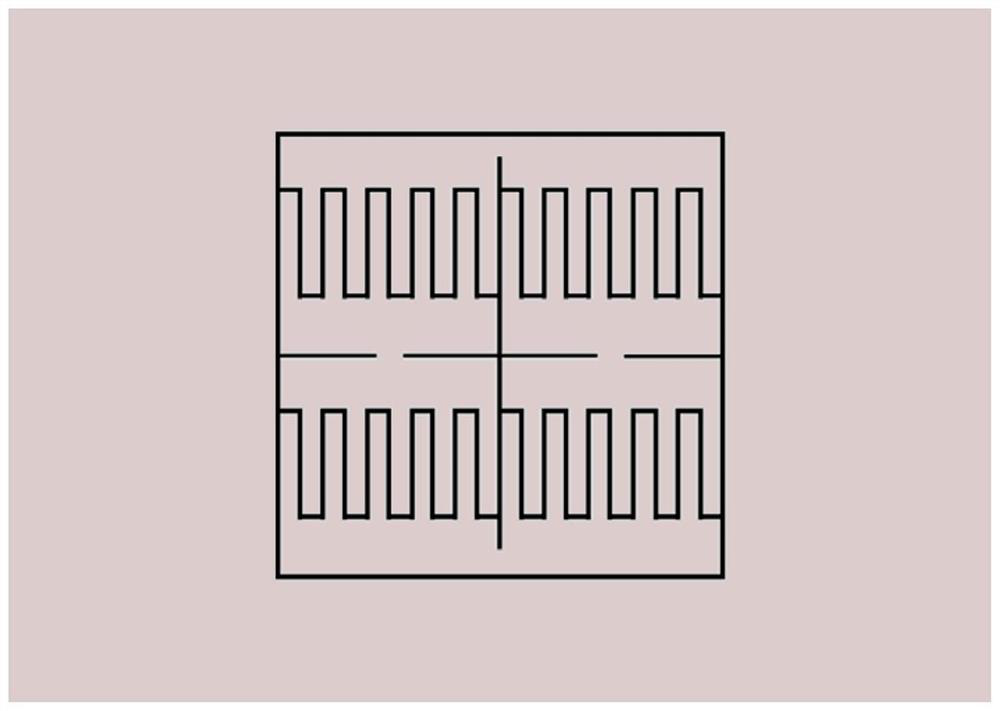

[0031] A 2×2 series-parallel array of interdigitated electrodes is processed on a two-dimensional material substrate by using a femtosecond laser. Turn on the femtosecond laser 1, adjust the aperture 2 so that the spot diameter is 4 mm, adjust the position of the telephoto high-power objective lens 7 so that the focus falls near the surface of the high-precision three-dimensional motion platform 9, close the electronically controlled shutter 5, turn on the CCD 11 and the lighting lamp 12, Adjust the height of the high-precision three-dimensional motion platform 9 and the CCD 11 to make the image clear, adjust the attenuation plate 4 to make the power of the femtosecond laser 5-10 μW, adjust the height of the high-precision three-dimensional motion platform 9 to focus the femtosecond laser on the two-dimensional material sample 8 , turn on the air pump 13, align the blowing port 14 with the two-dimensional material sample 8, adjust the air pressure of the air pump 13 to 20 kPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com