Self-water-absorption and self-power-generation type water treatment device and method based on sandwich structure electrode

A water treatment device and sandwich technology, which is applied in the fields of adsorption water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing the internal resistance of the battery, reducing the power and efficiency of electricity production, and restrictions, etc. To achieve the effect of reducing the internal resistance of the system, strengthening the capillary action, and improving the power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

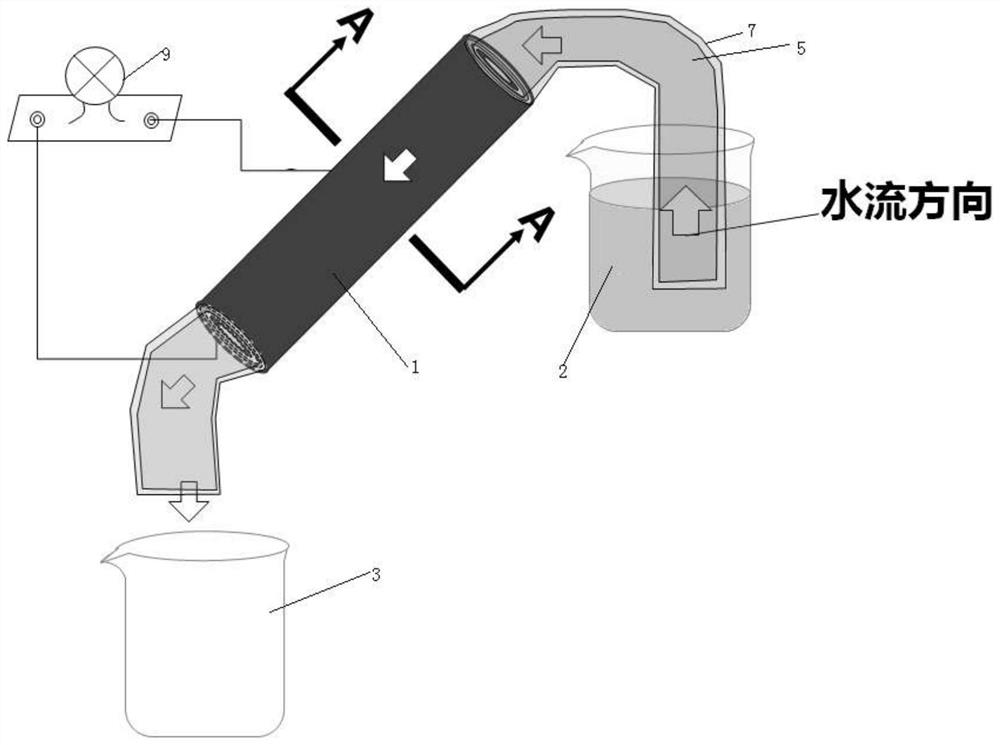

[0041] figure 1The self-absorbing water and self-generating water treatment device based on the sandwich structure electrode provided in this embodiment is a multi-layer roll structure schematic diagram, refer to figure 1 , the device includes: a sandwich structure electrode 1, a water inlet box 2 and a water production box 3.

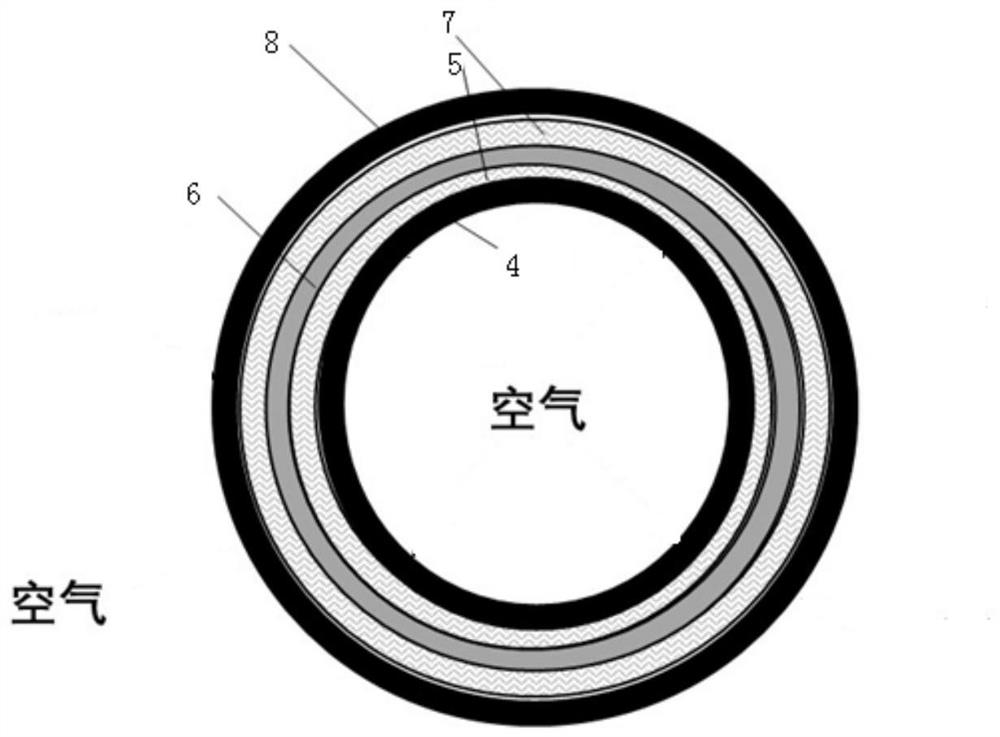

[0042] figure 2 It is the A-A cross-sectional view of the sandwich structure electrode multi-layer roll structure, refer to figure 2 , the sandwich structure electrode is a double positive electrode-single negative electrode structure composed of air positive electrode 4, separator material 5, film negative electrode 6, separator material 7 and air positive electrode 8 stacked in sequence, and the sandwich structure electrode is a multi-layer roll structure. In the embodiment, it is a hollow cylindrical structure. From the inside to the outside, there are air positive electrode 4, separator material 5, film negative electrode 6, separator material ...

Embodiment 2

[0056] This embodiment provides a self-absorbing self-generating water treatment device based on a sandwich electrode. The device includes: a sandwich electrode, a water inlet tank and a water production tank.

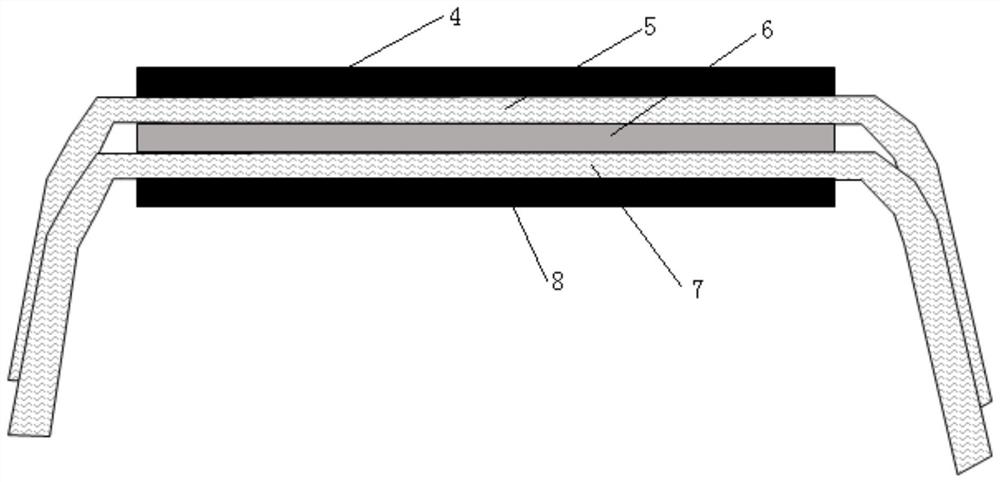

[0057] image 3 It is a schematic diagram of the sandwich structure electrode plate structure, refer to image 3 , the sandwich structure electrode is a double positive electrode-single negative electrode structure composed of air positive electrode 4, separator material 5, film negative electrode 6, separator material 7 and air positive electrode 8 stacked in sequence, and the sandwich structure electrode is a flat plate structure. Specifically, in this embodiment It is a cuboid structure, and from top to bottom are the air positive electrode 4, the separator material 5, the film negative electrode 6, the separator material 7 and the air positive electrode 8, wherein the separator material is in contact with the air positive electrode and the film negative electrode o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com