Anti-crack concrete

A concrete and anti-cracking fiber technology, applied in the field of concrete, can solve problems such as poor anti-cracking effect and easy cracks, and achieve the effects of improving strength and cracking resistance, reducing cracks, and increasing specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

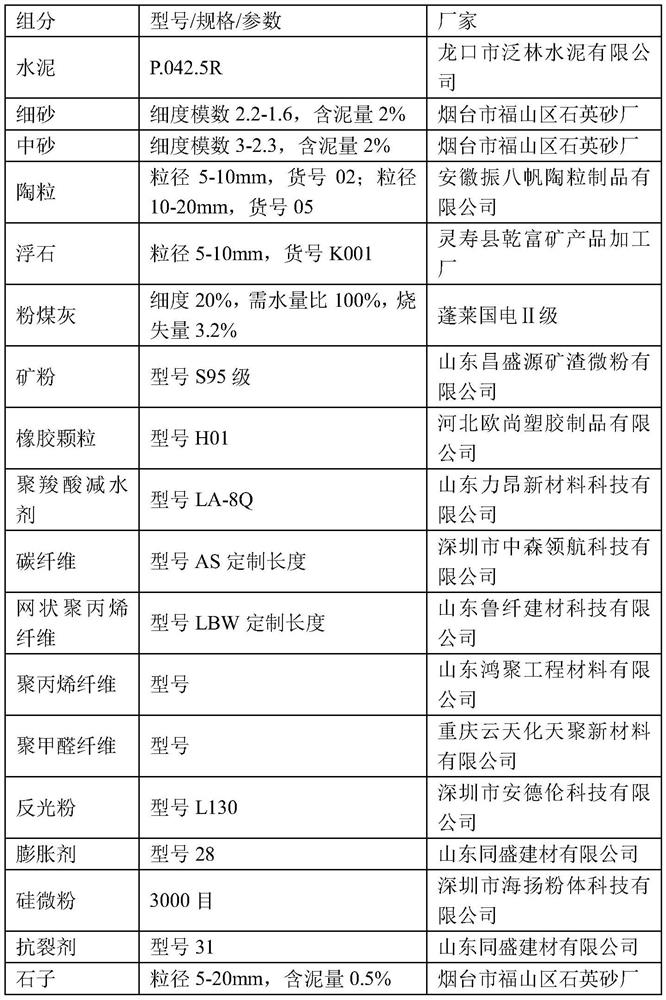

Method used

Image

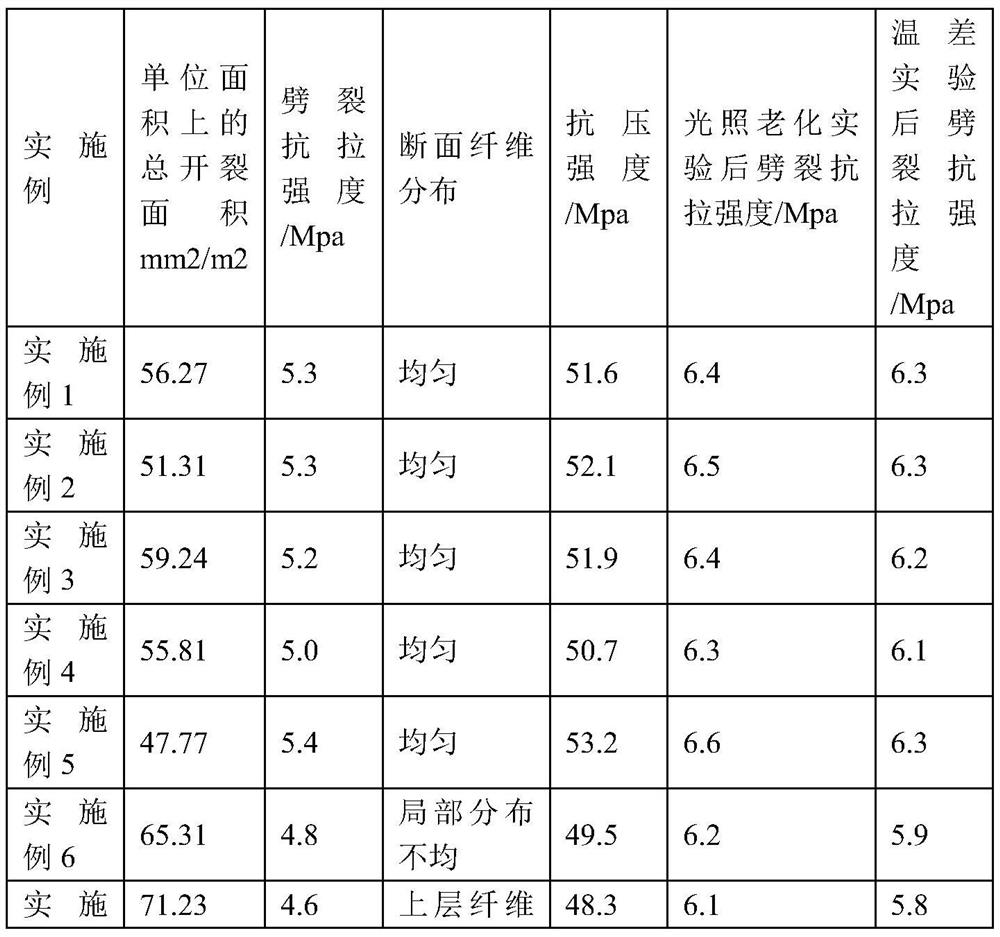

Examples

Embodiment 1

[0040] A kind of anti-crack concrete, its preparation steps are as follows:

[0041] At 25°C, firstly mix 30kg of cement, 25kg of fine aggregate, 40kg of coarse aggregate, 5kg of filler, and 10kg of rubber particles; add 15kg of water and mix evenly; , 0.8kg expansion agent and stir evenly.

[0042] The fine aggregate is fine sand with a fineness modulus of 1.6-2.2;

[0043] The coarse aggregate is ceramsite, and the particle size of the coarse aggregate is 5-10mm;

[0044] The filler is made of mineral powder and fly ash with a mass ratio of 1:1;

[0045] The water reducer is a polycarboxylate water reducer;

[0046] The crack-resistant fiber is mixed with carbon fiber, reticular polypropylene fiber and polyoxymethylene fiber with a mass ratio of 1:1.3:0.7, the length of the reticular polypropylene fiber is 17cm, and the length of the carbon fiber is 16cm. The length of polyoxymethylene fiber is 20cm;

[0047] The temperature of the water is 10°C;

[0048] The particle ...

Embodiment 2

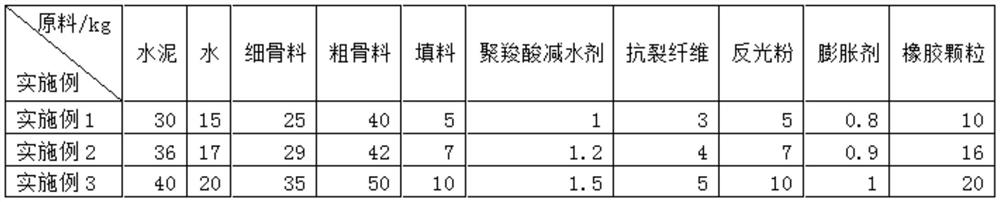

[0050] A crack-resistant concrete, the difference from Example 1 lies in: the ratio of raw materials is different, and the ratio of raw materials of each component is shown in Table 2.

[0051] Table 2

[0052]

Embodiment 3

[0054] A crack-resistant concrete, the difference from Example 1 lies in: the ratio of raw materials is different, and the ratio of raw materials of each component is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com