Phenylsilole-based conjugated microporous polymer as well as preparation method and application thereof

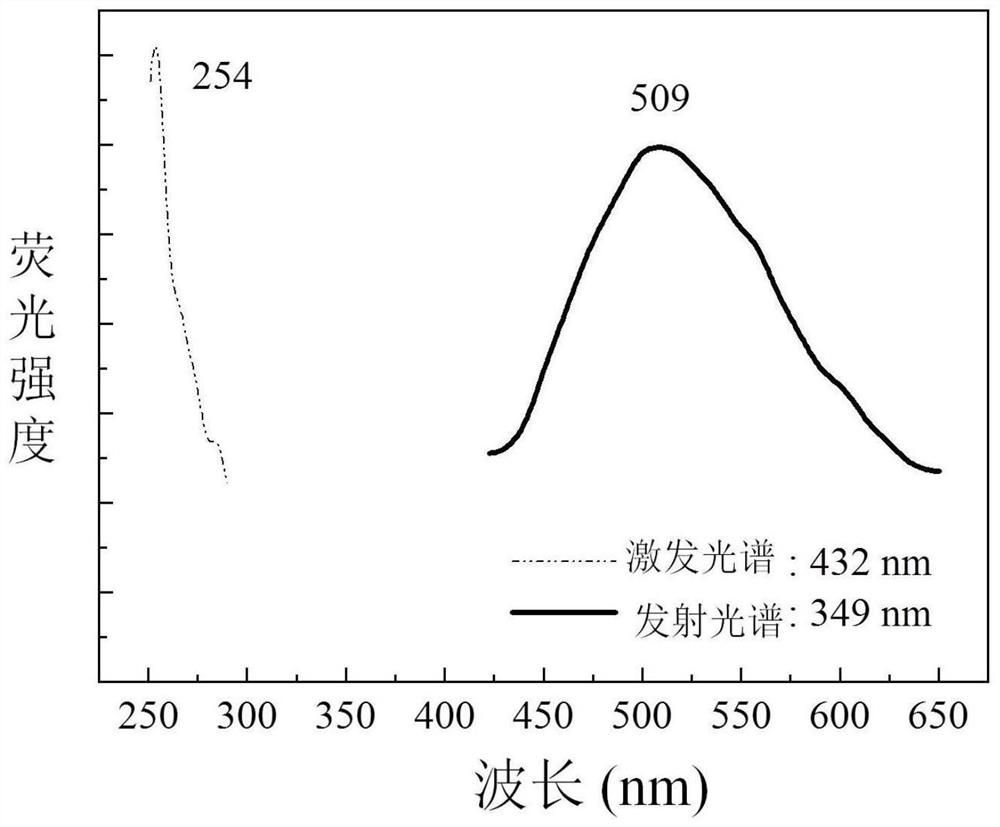

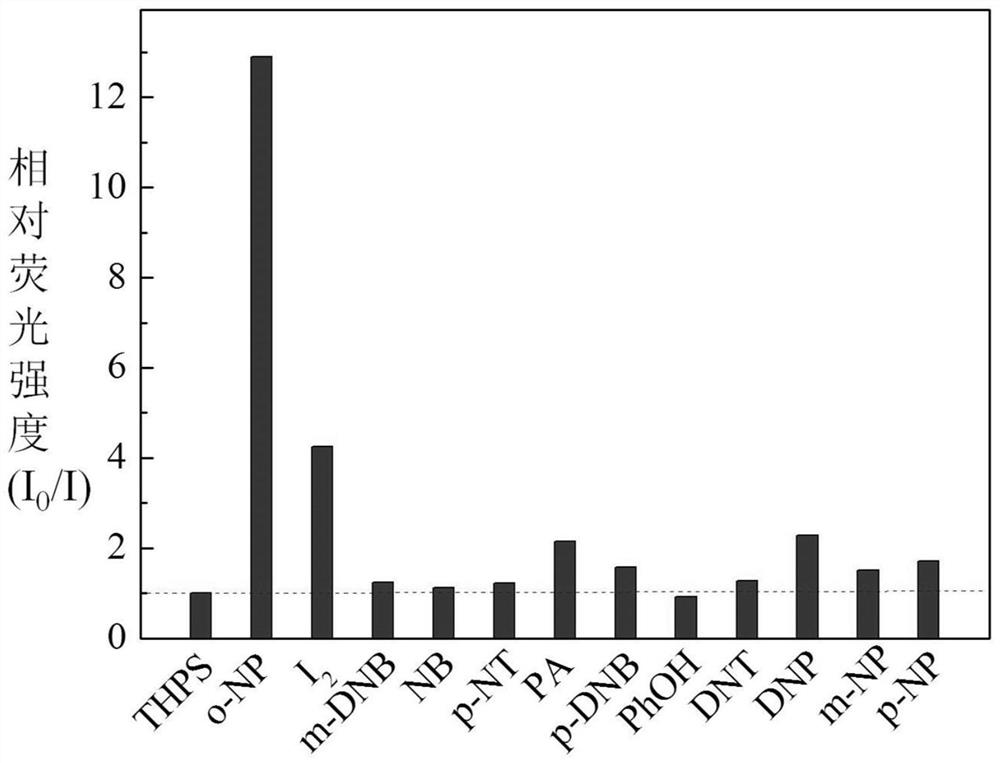

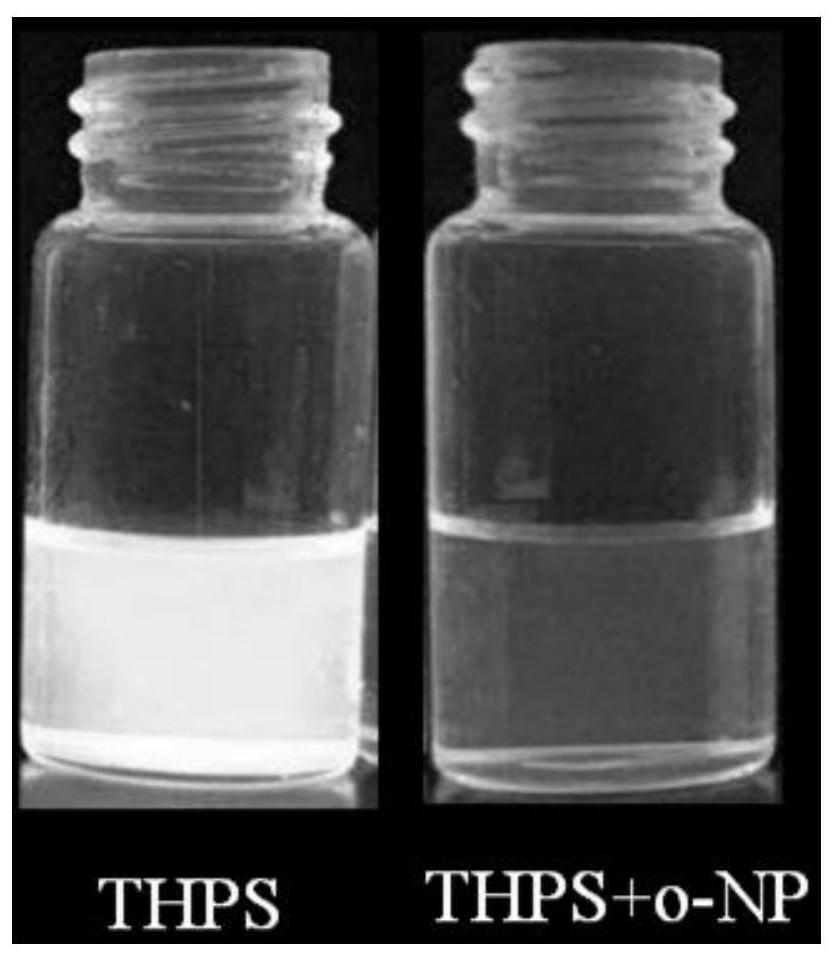

A phenylsilole-based and conjugated microporous technology, which is applied in the field of fluorescence sensing and detection, can solve problems such as health risks, no reports of phenylsilole-based conjugated microporous polymers, etc., and achieves easy operation, Good chemical and thermal stability, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of phenylsilolyl conjugated microporous polymer, comprising the steps of:

[0031] Hexaphenylsilole (0.8081g, 1.5mmol), cyanuric chloride (0.5532g, 3mmol), anhydrous AlCl 3 (1.4401g, 10.8mmol) was added to anhydrous dichloromethane (30mL), stirred evenly at room temperature; and nitrogen was passed through, placed in an oil bath and heated to 60°C, reacted for 24h, then cooled to room temperature, pumped filtered, the solid product was washed 3 times with methanol and chloroform, and then extracted with methanol and chloroform in a Soxhlet extractor for 24 hours, and finally dried in a vacuum oven at 50°C to obtain phenylsilolyl conjugated microporous polymer Things, denoted as THPS.

Embodiment 2

[0033] A preparation method of phenylsilolyl conjugated microporous polymer, comprising the steps of:

[0034] 1,1-dimethyl-2,3,4,5-tetraphenylsilole (0.6219g, 1.5mmol), cyanuric chloride (0.3690g, 2mmol), anhydrous AlCl 3(1.4401g, 10.8mmol) was added to chloroform (30mL), stirred evenly at room temperature; and nitrogen was passed through, placed in an oil bath and heated to 80°C, reacted for 20h, then cooled to room temperature, suction filtered, and the solid product Wash with methanol and chloroform three times respectively, then extract with methanol and chloroform in a Soxhlet extractor for 24 hours, and finally dry in a vacuum oven at 60°C to obtain a phenylsilolyl-conjugated microporous polymer, which is denoted as TTPs.

Embodiment 3

[0036] A preparation method of phenylsilolyl conjugated microporous polymer, comprising the steps of:

[0037] 1-methyl-1,2,3,4,5-pentaphenylsilole (0.7150g, 1.5mmol), cyanuric chloride (0.4613g, 2.5mmol), anhydrous AlCl 3 (1.4401g, 10.8mmol) was added to anhydrous dichloroethane (30mL), stirred evenly at room temperature; and nitrogen was passed through, placed in an oil bath and heated to 100°C, reacted for 16h, and then cooled to room temperature, Suction filtration, the solid product was washed 3 times with methanol and chloroform respectively, and then extracted with methanol and chloroform in a Soxhlet extractor for 24 hours, and finally dried in a vacuum oven at 100°C to obtain phenylsilolyl-conjugated microporous Polymer, denoted as TPPS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com