Screening and application of bacillus strain for producing cellulase

A technology of cellulase and Bacillus subtilis, applied in the field of bioengineering, can solve problems such as low production efficiency, low cellulase output, and difficult operation, and achieve environmental protection, good generation stability, and simple and easy process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the screening of bacterial strain

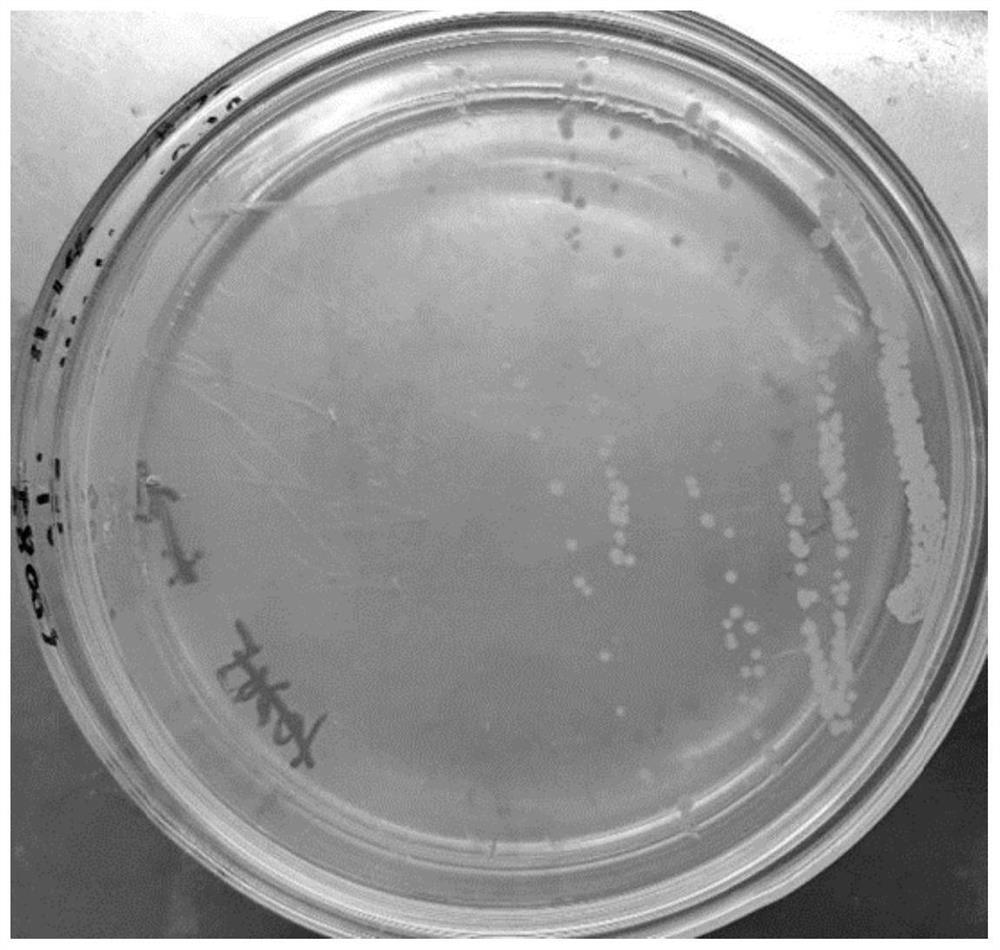

[0041] (1) Screening of Bacillus subtilis producing cellulase

[0042] Preliminary screening process: Take an appropriate amount of animal feces samples, dissolve them in 100mL of sterilized distilled water, put them in a shaker, shake at 30°C and 200r / min for 30min for enrichment culture. Take the supernatant for ten-fold dilution, draw 10 -4 、10 -5 、10 -6 、10 -7 、10 -8They were respectively coated on CMC-Na screening plates and incubated in a 30°C incubator for 24 hours. Since non-cellulase-producing strains do not produce transparent circles, cellulase-producing strains will appear transparent circles. Therefore, the range of potential strains is determined according to whether there is a cellulose-degrading transparent circle;

[0043] Re-screening process: Use the basal medium to isolate and select the strains with potential cellulose degrading ability. Because the ratio of the diameter of the transparent ci...

Embodiment 2

[0055] Embodiment 2: Bacillus subtilis FMME ZK002 shake flask fermentation

[0056] Step 1: Prepare medium

[0057] Carboxymethylcellulose sodium (CMC-Na) screening medium (g / L): CMC-Na 10, (NH 4 ) 2 SO 4 4. Peptone 1, MgSO 4 ·7H 2 O 0.5, KH 2 PO 4 1. Sterilize at 121°C for 15 minutes;

[0058] Solid activation medium (g / L): sodium chloride 5, beef extract 10, peptone 10, agar 20, distilled water 1.0L.

[0059] Liquid seed medium (g / L): sodium chloride 5, beef extract 10, peptone 10, distilled water 1.0L.

[0060] Liquid fermentation medium (g / L): sodium chloride 5, beef extract 10, peptone 10, distilled water 1.0L.

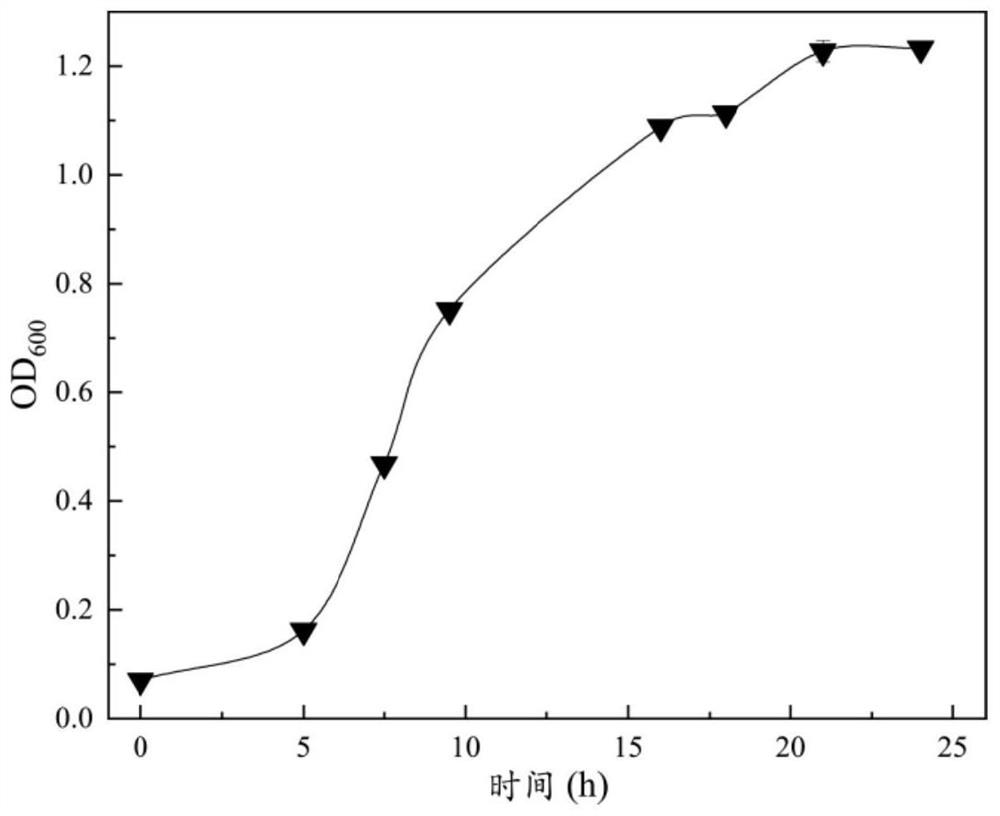

[0061] Step 2: Seed Preparation

[0062] Dip the bacterial suspension of the strain, streak it on the solid medium, cultivate it in a constant temperature incubator at 30°C for about 24 hours to obtain a single colony, pick a single colony and put it into a 100mL conical flask containing 25mL of liquid seed medium, Cultivate overnight at 30° C. in a ...

Embodiment 3

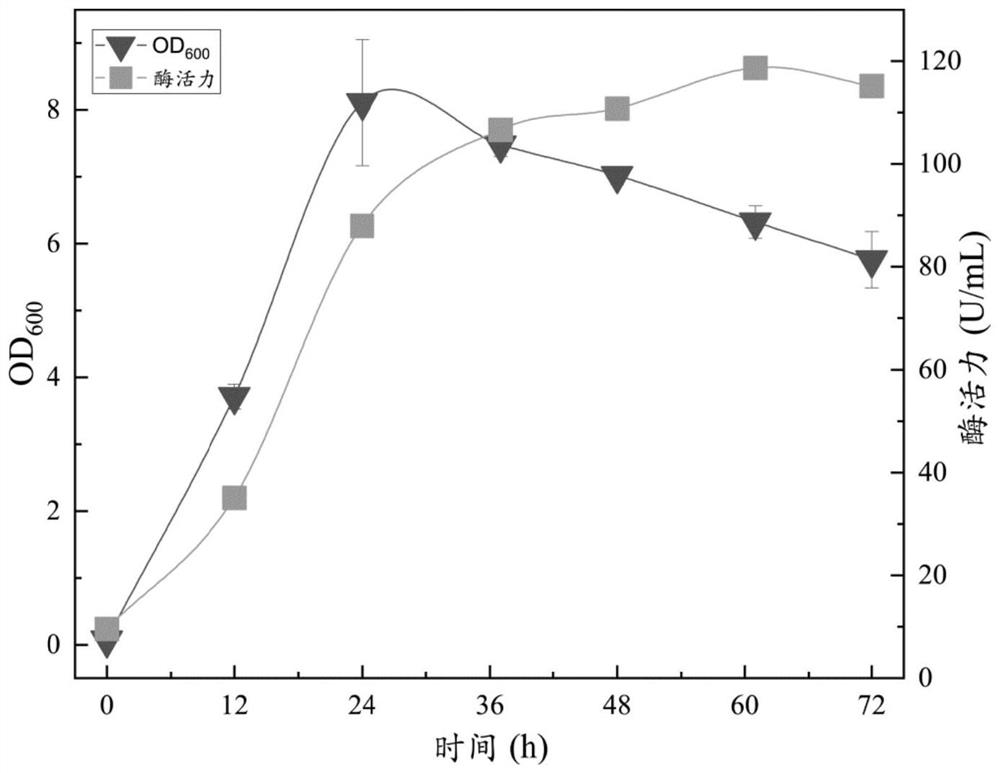

[0065] Embodiment 3: subtilis Bacillus subtilisFMME ZK002 passage stability

[0066] For specific embodiments, referring to Example 2, the screened Bacillus subtilis FMMEZK002 was subcultured for 12 generations, and the strains of each generation were inoculated into the fermentation medium for shake-flask fermentation. After the fermentation, the cellulase activity was measured. After the subculture, the cellulase activity was shown in Table 2, and the enzyme activity was maintained at 108-118.67U / mL, which indicated that Bacillus subtilisFMME ZK002 has high passage stability.

[0067] The cellulase activity of table 2 subculture strain

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com