Steel wheel heat treatment system and method

A heat treatment system and heat treatment method technology, applied in the field of steel wheel heat treatment system, can solve the problems of quenching medium pollution, wheel deformation, affecting quenching and heat preservation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the specific structure and layout of the steel wheel heat treatment system of the present application will be described in detail with reference to the accompanying drawings.

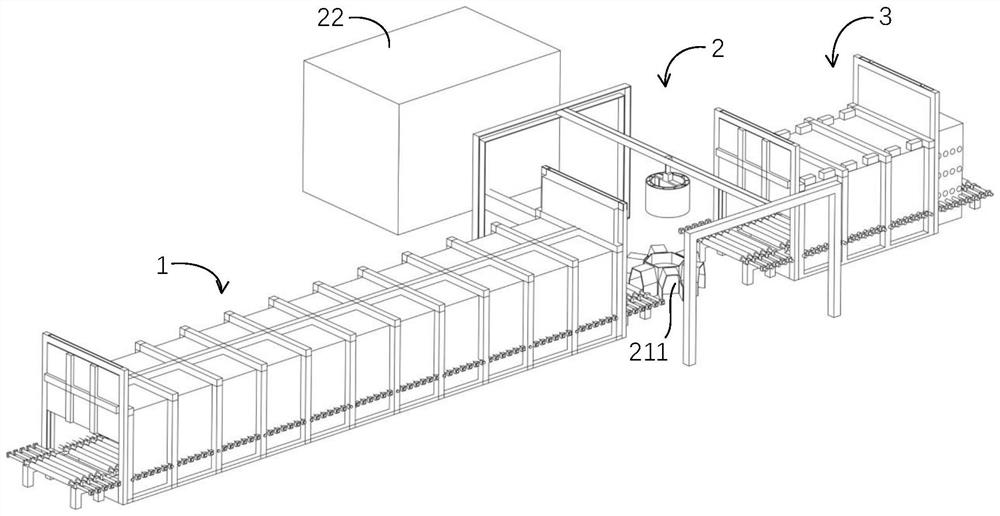

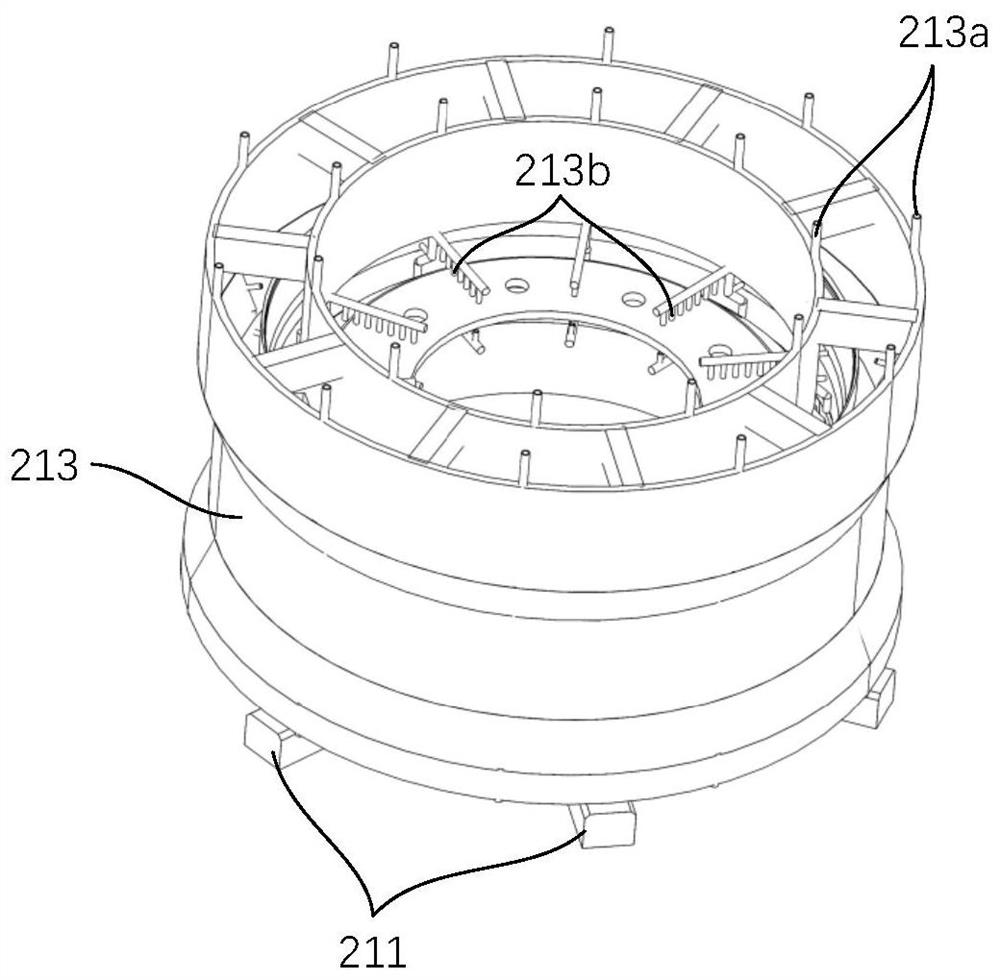

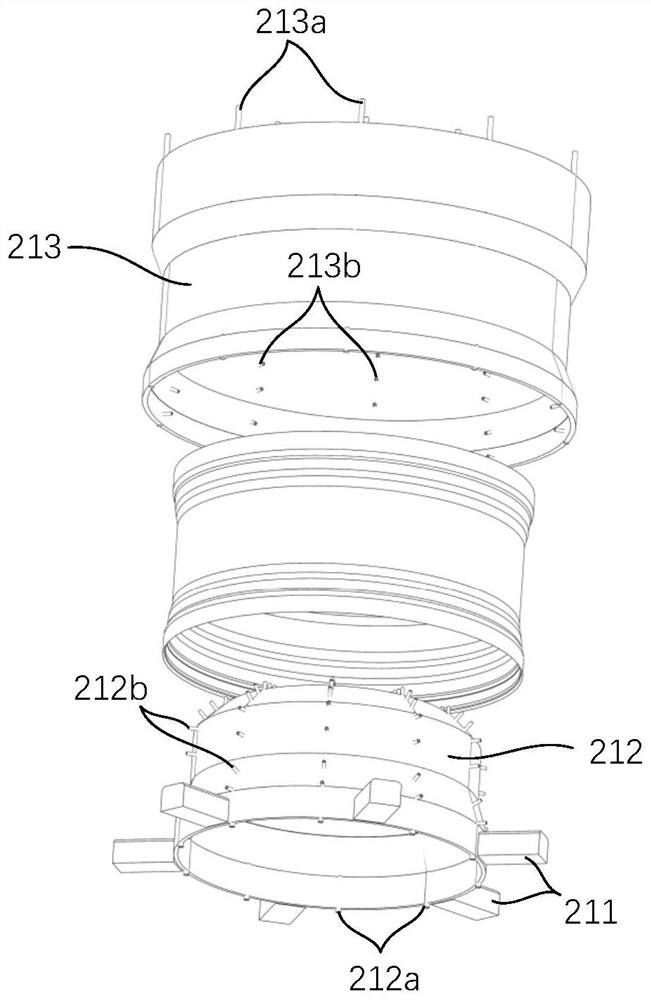

[0032] figure 1 It is a schematic diagram of the distribution of the steel wheel heat treatment system of the present application. Such as figure 1 As shown, the steel wheel heat treatment system of the present application includes: the first heating furnace 1 (roller hearth heating furnace in the figure, can also adopt forms such as walking heating furnace), cooling device 2, second heating furnace 3 (figure The middle is a roller hearth heating furnace, and a walking heating furnace can also be used) in three parts. Among them, the first heating furnace 1 is used to heat the steel wheel, so that the inner structure of the steel wheel is completely transformed into austenite; The steel wheel is uniformly cooled by a controllable jet flow, so that the cooling rate of each part of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com