Pre-ignition chamber fuel supply system and engine

A technology of fuel supply system and pre-combustion chamber, which is applied in the direction of combustion engine, internal combustion piston engine, machine/engine, etc. It can solve the problems of increased uncertainty of flame development, difficulty in cold start, and large engine cycle changes, so as to avoid coking and soot generation, improve ignition stability, and reduce the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

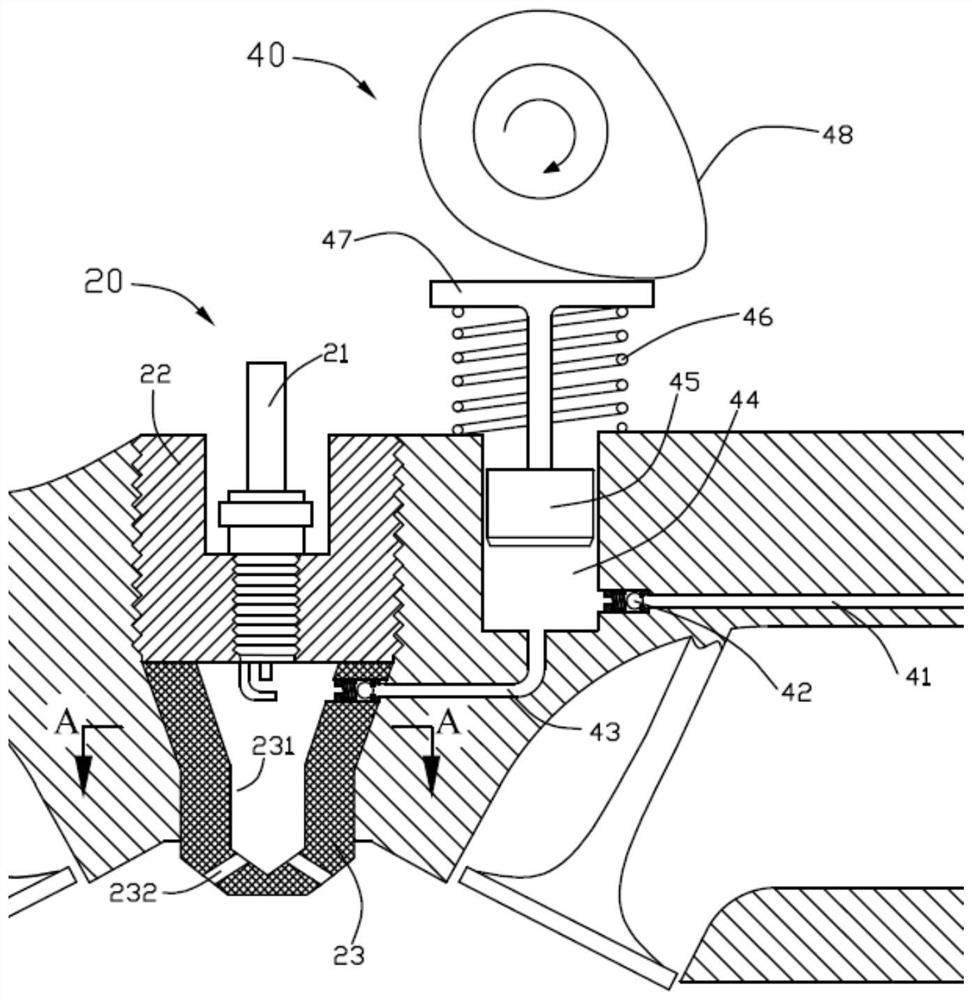

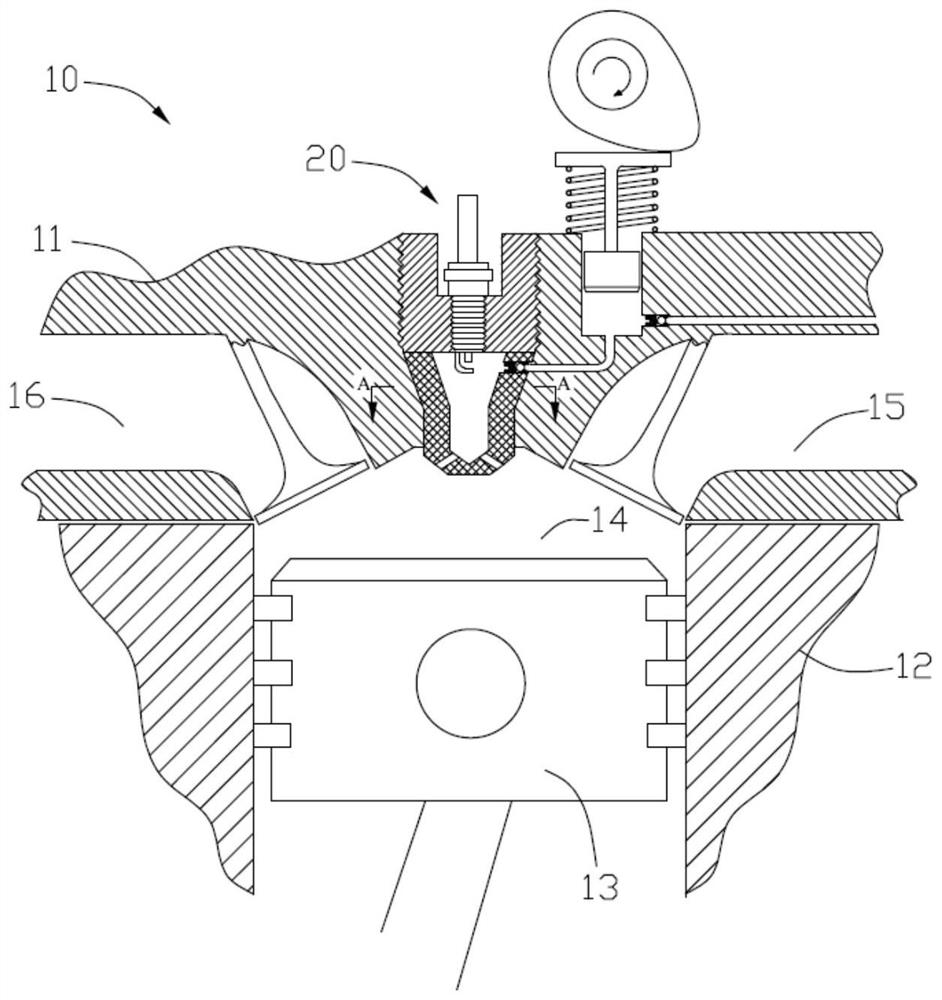

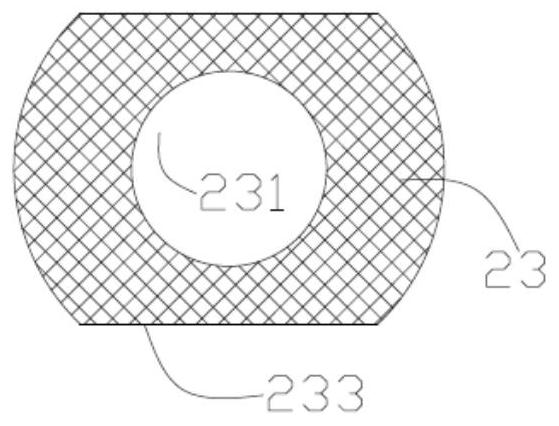

[0029] Please refer to Figure 1 to Figure 5 , the pre-chamber fuel supply system of the embodiment of the present invention is used for the engine 10, including the pre-chamber device 20 and the air intake device, the front end of the air intake device communicates with the throttle valve 51, the rear end communicates with the pre-chamber device 20, and the pre-combustion chamber The chamber device 20 communicates with the engine 10 . The intake device includes an intake pipe 52 , a first compression device 53 , a gasification mixing device 54 , a second compression device 40 and a pre-chamber check valve 30 . The intake pipe 52 communicates with the first compression d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com