Preparation method of whey protein

A whey protein and seed technology, applied in the field of microbial fermentation, can solve the problems of reducing the nutritional value of protein, reducing allergenicity, reducing milk protein allergenicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

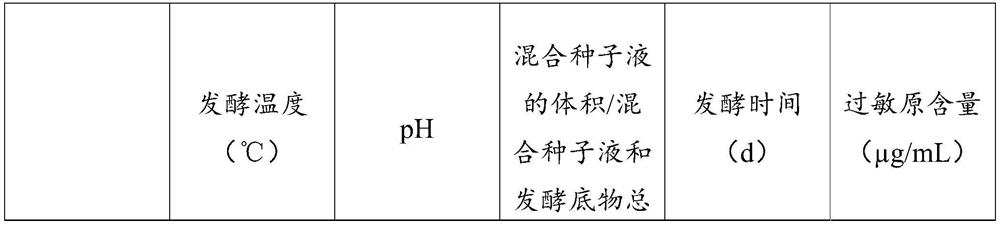

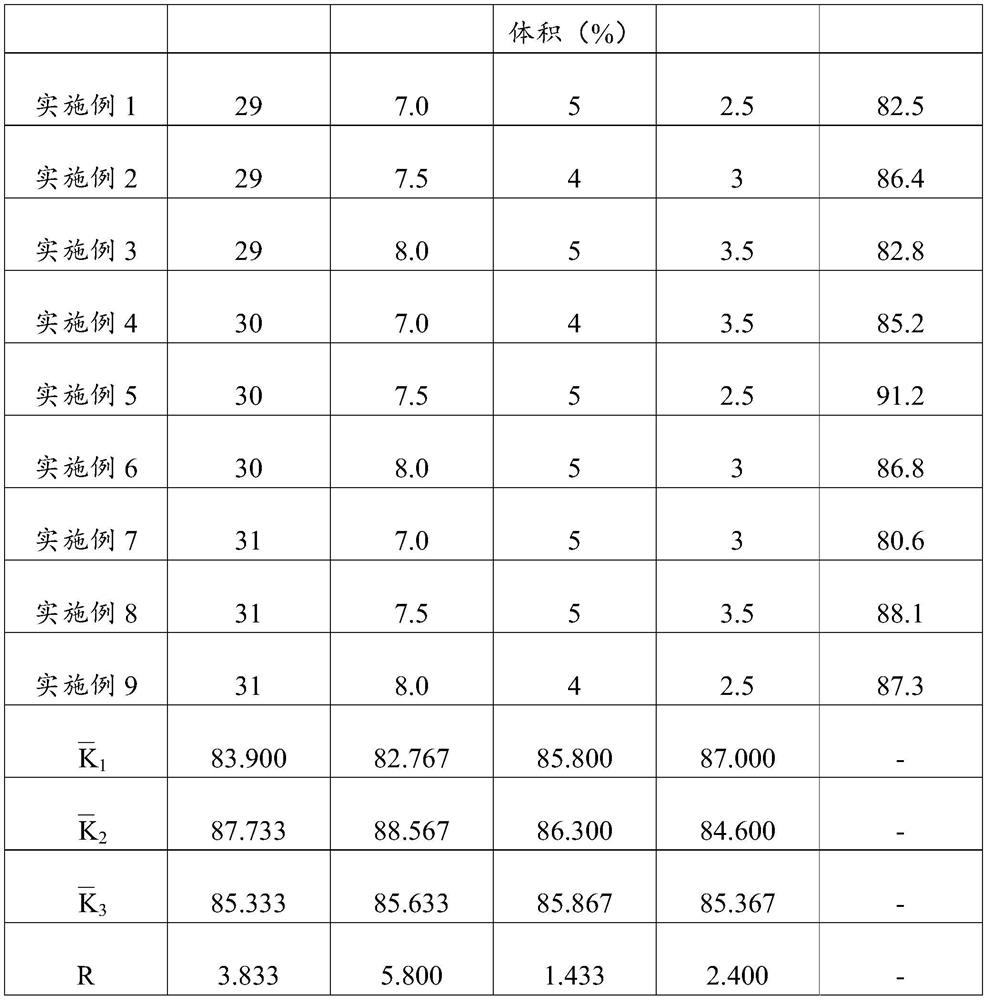

Examples

Embodiment 10

[0038] An embodiment of the present application, the technical solution adopted in this embodiment is: a preparation method of whey protein, comprising the following steps:

[0039] (1) Prepare mixed seed liquid; take Bifidobacterium lactis strain and Streptococcus acidophilus strain respectively, carry out constant temperature culture first, then inoculate in seed culture medium and carry out expansion culture, shake culture again, obtain Bifidobacterium lactis seed liquid respectively and Streptococcus acidophilus seed liquid, mixing Bifidobacterium lactis seed liquid and Streptococcus acidophilus seed liquid to obtain mixed seed liquid, the mass ratio of Bifidobacterium lactis and Streptococcus acidophilus in the mixed seed liquid is: Bifidobacterium lactis Bacillus: Streptococcus acidophilus = 1:1;

[0040] The temperature of constant temperature culture is 25°C; the temperature of expansion culture is 25°C, and the time of expansion culture is 24h; the temperature of shak...

Embodiment 11

[0043] An embodiment of the present application, the technical solution adopted in this embodiment is: a preparation method of whey protein, comprising the following steps:

[0044] (1) Prepare mixed seed liquid; take Bifidobacterium lactis strain and Streptococcus acidophilus strain respectively, carry out constant temperature culture first, then inoculate in seed culture medium and carry out expansion culture, shake culture again, obtain Bifidobacterium lactis seed liquid respectively and Streptococcus acidophilus seed liquid, mixing Bifidobacterium lactis seed liquid and Streptococcus acidophilus seed liquid to obtain mixed seed liquid, the mass ratio of Bifidobacterium lactis and Streptococcus acidophilus in the mixed seed liquid is: Bifidobacterium lactis Bacillus: Streptococcus acidophilus = 1:1;

[0045] The temperature of constant temperature culture is 28°C; the temperature of expansion culture is 28°C, and the time of expansion culture is 36h; the temperature of shak...

Embodiment 12

[0048] An embodiment of the present application, the technical solution adopted in this embodiment is: a preparation method of whey protein, comprising the following steps:

[0049] (1) Prepare mixed seed liquid; take Bifidobacterium lactis strain and Streptococcus acidophilus strain respectively, carry out constant temperature culture first, then inoculate in seed culture medium and carry out expansion culture, shake culture again, obtain Bifidobacterium lactis seed liquid respectively and Streptococcus acidophilus seed liquid, mixing Bifidobacterium lactis seed liquid and Streptococcus acidophilus seed liquid to obtain mixed seed liquid, the mass ratio of Bifidobacterium lactis and Streptococcus acidophilus in the mixed seed liquid is: Bifidobacterium lactis Bacillus: Streptococcus acidophilus = 1:1;

[0050] The temperature of constant temperature culture is 30°C; the temperature of expansion culture is 30°C, and the time of expansion culture is 48h; the temperature of shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com