Equipment and production process for purifying montmorillonite from high-grade bentonite ore through dry method

A technology of dry purification and bentonite, which is used in cyclone devices, grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

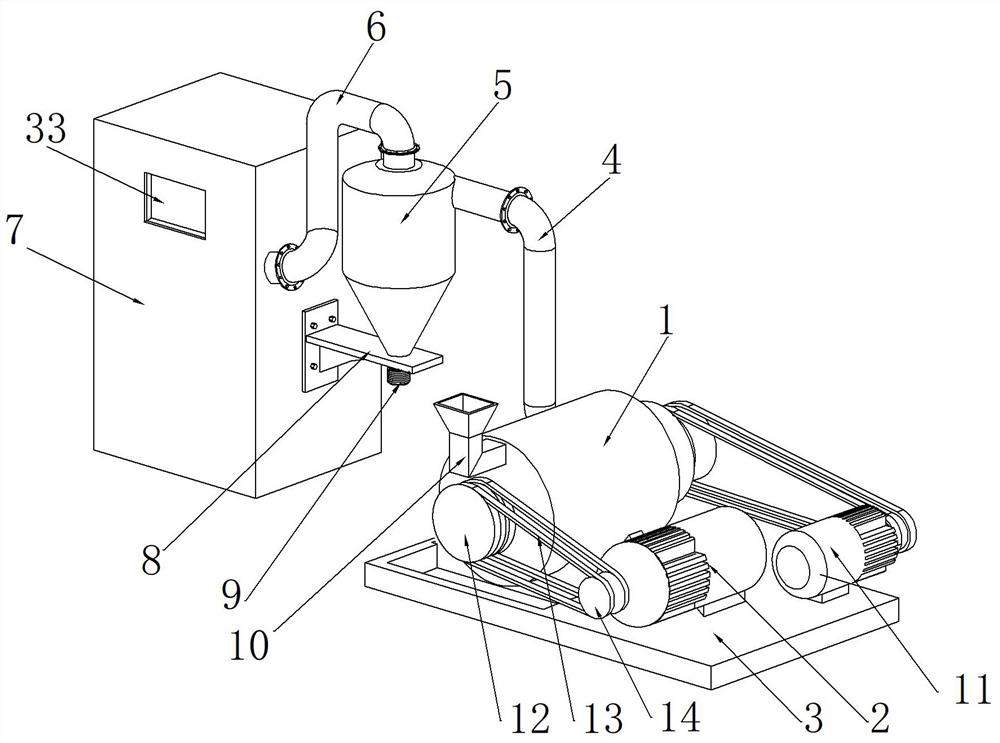

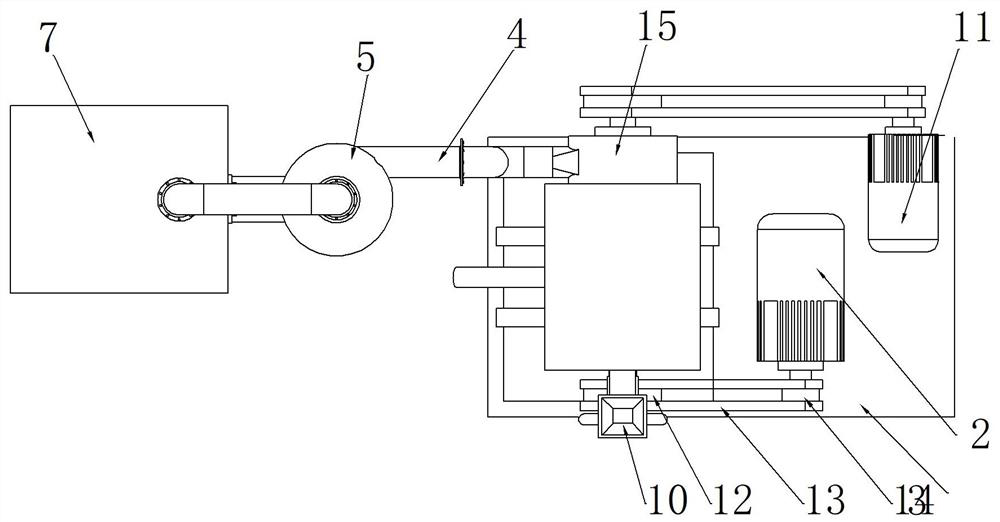

[0025] Embodiment 1: as attached Figure 1-5 As shown, a kind of equipment for dry purification of montmorillonite from high-grade bentonite ore includes an equipment mounting base 3, and a bentonite material crushing device 1 and a drive motor 2 are fixedly installed on the equipment mounting base 3, and the drive motor 2 and Bentonite material crushing device 1 transmission connection, described bentonite material crushing device 1 comprises crushing device shell 17, propulsion shaft 20, spiral crushing knife 21, crushing reamer 22, barrel wall reamer 19 and air-sent material cover 15, and the wind sends The material cover 15 is connected with an air supply purification system, the propulsion shaft 20 is rotated and placed in the shell 17 of the crushing device through a bearing 27, the spiral crushing knife 21 and the crushing reamer 22 are fixedly installed on the propulsion shaft 20 in sequence, and the barrel The wall reamer 19 is arranged on the inner wall of the crushi...

Embodiment 2

[0031] Embodiment 2: a kind of production technology of high-grade bentonite ore dry purification montmorillonite, adopts the equipment processing of above-mentioned high-grade bentonite ore dry purification montmorillonite, comprises the following operation steps:

[0032] S1: First, start the drive motor 2, the air blower motor 11 and the vibration motor 34, the drive motor 2 drives the bentonite material crushing device 1 through the drive belt 13, the motor drive turntable 14 and the crushing device drive turntable 12, and the bentonite raw material is fed through the raw material The bucket 10 is put into the bentonite material crushing device 1, and the propulsion shaft 20 rotating inside drives the spiral crushing knife 21 to rotate. The spiral crushing knife 21 initially crushes the larger bentonite block and drives the raw material to the direction of the crushing reamer 22. The crushed bentonite raw material enters the crushing gap between the crushing reamer 22 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com