Solid oxidability testing device, testing method and sampler thereof

A sampler and oxidation technology, applied in the field of chemical hazard detection, can solve the problems of low accuracy and reproducibility of solid oxidation test results, low efficiency of solid oxidation test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

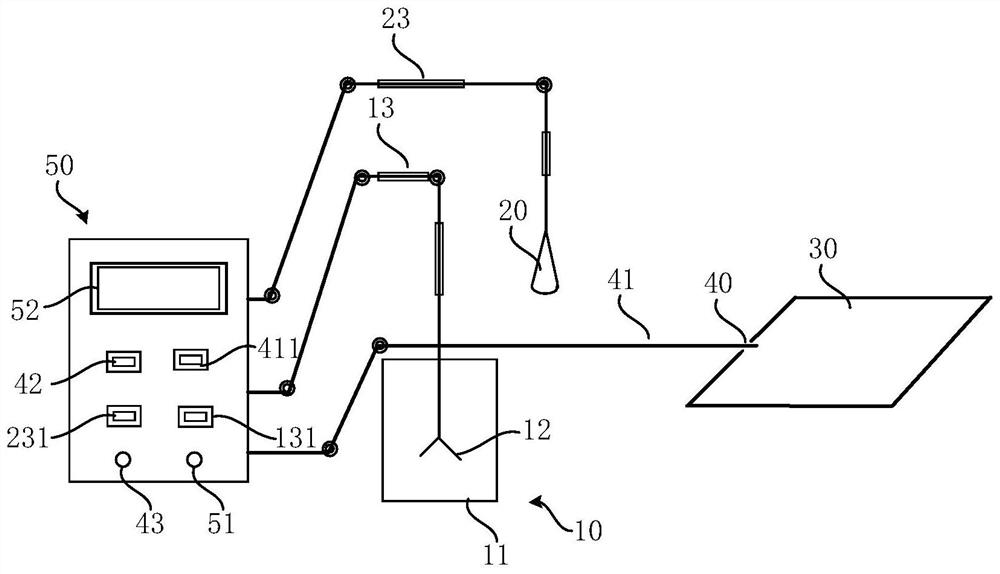

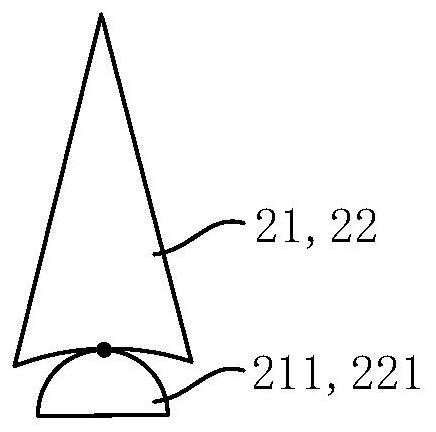

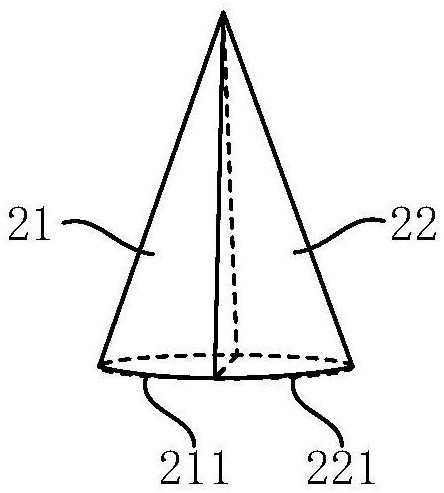

[0053] The oxidizability of the sodium nitrate particles is tested by using the solid oxidizability test device of the present invention, and the reference substance is potassium bromate. The device of this embodiment is placed in a ventilated area, and the test is carried out under atmospheric pressure and an ambient temperature of 20°C±5°C. refer to Figure 1~4 shown. The generatrix of the conical container of the sampler 20 is 70mm long, and the cone angle is 60°.

[0054] (1) Prepare the reference substance potassium bromate (nominal particle size 0.15-0.30mm), dry it to a constant weight (at least 12 hours) at 65°C, and then put it in a desiccator (with desiccant) until it cools down before use. Prepare the cellulose and dry it at 105°C to a constant weight (at least 4 hours), and then put it in a desiccator (with a desiccant) until it cools down before use, ensuring that the moisture content should be less than 0.5% by dry weight.

Embodiment 2

[0070] In this embodiment, the solid oxidizing property test device of the present invention is used to test the oxidizing property of sodium nitrite particles, and the reference substance is potassium bromate. The test procedure is the same as in Example 1.

[0071] The test results show that the sodium nitrite particles measured in this embodiment are "oxidizing solids, category 2". The entire test process of this embodiment takes 50 minutes, and the test results are the same as the example classification of the oxidative test results of solid oxidizing sodium nitrite particles in the "Test and Standard Manual", and the standard deviation of each group of tests is less than 5, and the test accuracy is high , good repeatability.

Embodiment 3

[0073] In this embodiment, the oxidizability of calcium nitrate tetrahydrate (granular) is tested by using the solid oxidizing test device of the present invention, and the reference substance is potassium bromate. The test procedure is the same as in Example 1.

[0074] The test results show that the calcium nitrate tetrahydrate measured in this embodiment is "oxidizing solid, category 3". The whole test process of this embodiment takes 60 minutes, and the test result is the same as the "Test and Standard Manual" solid oxidizable calcium nitrate (water of crystallization) oxidation test result example classification, and the standard deviation of each group of tests is all less than 6, and the test is accurate High accuracy and good repeatability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com