Composite lithium supplementing diaphragm and secondary battery thereof

A separator and lithium replenishment technology, applied in secondary batteries, secondary battery repair/maintenance, battery pack components, etc., can solve the problems of active lithium deactivation, no protective layer, safety risks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

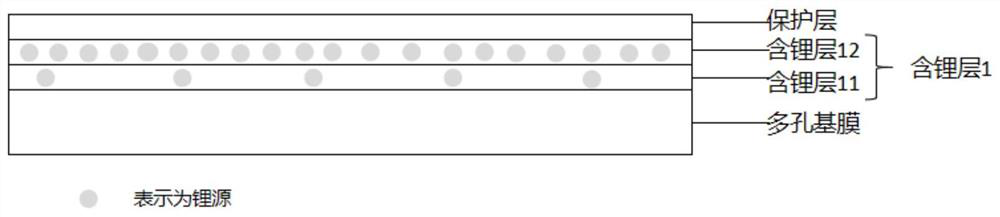

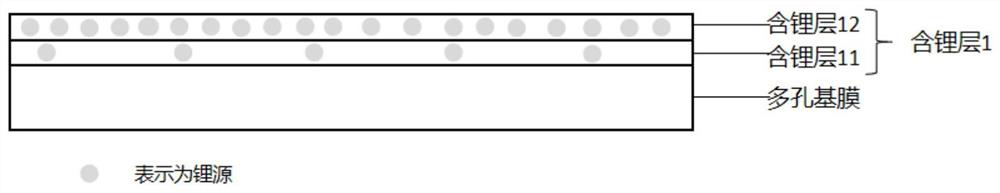

[0028] Such as figure 1 As shown, the composite lithium-supplementing diaphragm porous base membrane (PP film, 9 μm); a lithium-containing layer 1 is provided on one side of the base membrane, and the lithium-containing layer 1 is composed of a lithium-containing layer 11 and a lithium-containing layer 12, and is close to the base membrane. The mass proportion of the lithium source in the lithium-containing layer 11 is 10%, and the thickness is 2 μm; the mass proportion of the lithium source in the lithium-containing layer 12 away from the porous base film is 50%, and the thickness is 2 μm; An inorganic ceramic protective layer is provided with a thickness of 2 μm and a porosity of 30%.

[0029] 1) The preparation method of lithium-replenishing composite diaphragm, comprises the following steps:

[0030] a) Preparation and coating of lithium-containing layer 11 slurry

[0031] The lithium powder SLMP, styrene-butadiene rubber, silicon dioxide and NMP are mixed according to t...

Embodiment 2

[0038] Such as figure 1 As shown, the composite lithium-supplementing diaphragm porous base membrane (PP film, 9 μm); a lithium-containing layer 1 is provided on one side of the base membrane, and the lithium-containing layer 1 is composed of a lithium-containing layer 11 and a lithium-containing layer 12, and is close to the base membrane. The mass proportion of the lithium source in the lithium-containing layer 11 is 20%, and the thickness is 2 μm; the mass proportion of the lithium source in the lithium-containing layer 12 away from the porous base film is 60%, and the thickness is 3 μm; An inorganic ceramic protective layer is provided with a thickness of 1 μm and a porosity of 15%.

[0039] 1) The preparation method of lithium-replenishing composite diaphragm, comprises the following steps:

[0040] a) Preparation and coating of lithium-containing layer 11 slurry

[0041] The lithium supplement material Li 2 O, PVDF, Al 2 o 3 Mix with NMP according to the ratio of 2:...

Embodiment 3

[0048] Such as figure 1 As shown, the porous base membrane (PE film, 12 μm) of the composite lithium-supplementing separator; a lithium-containing layer 1 is provided on one side of the base membrane, and the lithium-containing layer 1 is composed of a lithium-containing layer 11 and a lithium-containing layer 12, and is close to the base membrane. The mass proportion of the lithium source in the lithium-containing layer 11 is 15%, and the thickness is 2 μm. The mass proportion of the lithium source in the lithium-containing layer 12 away from the porous base film is 45%, and the thickness is 2 μm; An inorganic ceramic protective layer is provided with a thickness of 1 μm and a porosity of 25%.

[0049] 1) The preparation method of lithium-replenishing composite diaphragm, comprises the following steps:

[0050] a) Preparation and coating of lithium-containing layer 11 slurry

[0051] The lithium powder SLMP, styrene-butadiene rubber, silicon dioxide and NMP are mixed accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com