Preparation method of pepper-flavor slow-release salt

A slow-release salt and flavor technology, which is applied in the forming of food, food ingredients as odor modifiers, and food ingredients as taste modifiers, etc., can solve the problems of not long-lasting numbness, difficult preservation, and unstable fragrance substances, etc. Achieve the effect of ensuring quality, ensuring stability, and outstanding emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] A pepper flavor slow-release salt, made of the following raw materials in proportion by weight

[0092] Concentrated whey protein 0.27g, pectin 0.12g, chitosan 0.18g, pepper oleoresin 3g, salt 39g, distilled water 90g.

[0093] (1) Dissolve 0.27g of concentrated whey protein in 30g of saturated sodium chloride aqueous solution at 100°C, add 3g of Zanthoxylum bungeanum oleoresin, adjust the pH to 7, and use a high-speed shearing machine at 10000r / min to homogeneously stir for 2min to obtain a grade emulsion;

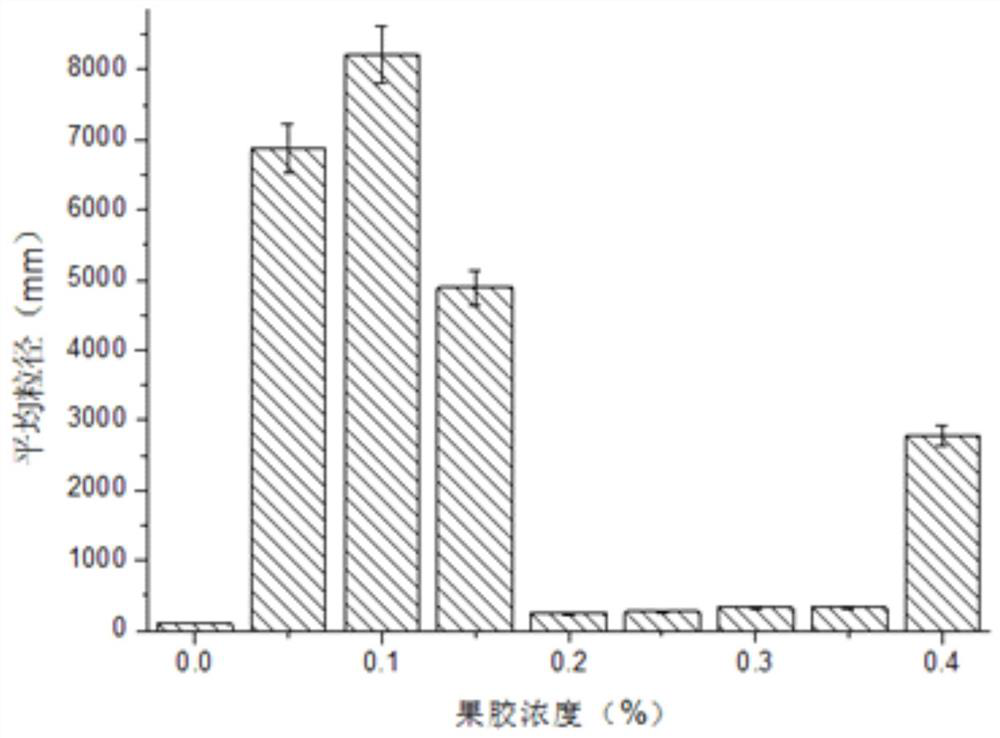

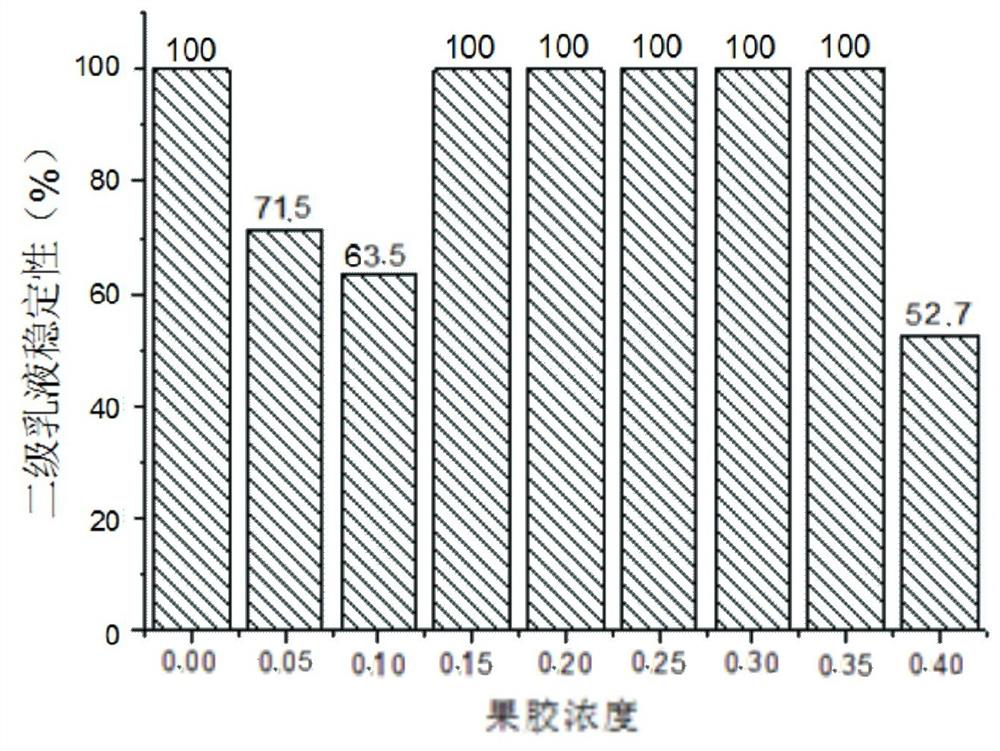

[0094] (2) Add 30g of saturated sodium chloride aqueous solution at 100°C to the first-grade emulsion, then add 0.12g of pectin, add acetic acid buffer to adjust the pH to 3.5 with a plastic dropper, and treat with 1000W ultrasonic for 5min to destroy the flocculation , to obtain a secondary emulsion;

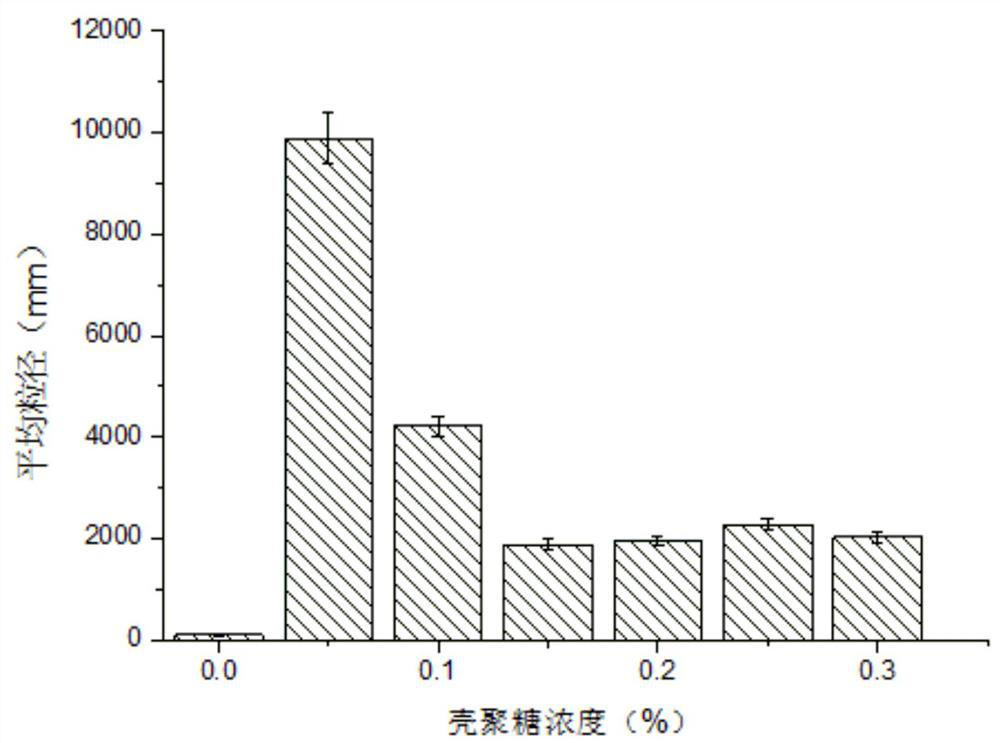

[0095] (3) Add 30g of saturated sodium chloride aqueous solution at 100°C to the secondary emulsion, then add 0.18g of chitosan, and add acetic acid buffer dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com