Elevated cargo automatic grabbing and placing loading and unloading robot

An overhead, robotic technology, applied in loading/unloading, packaging, stacking of objects, etc., can solve the problems of manual handling safety hazards, increased grasping, difficulty, etc., to reduce personnel consumption and labor costs, and improve the application. Scope and flexibility, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

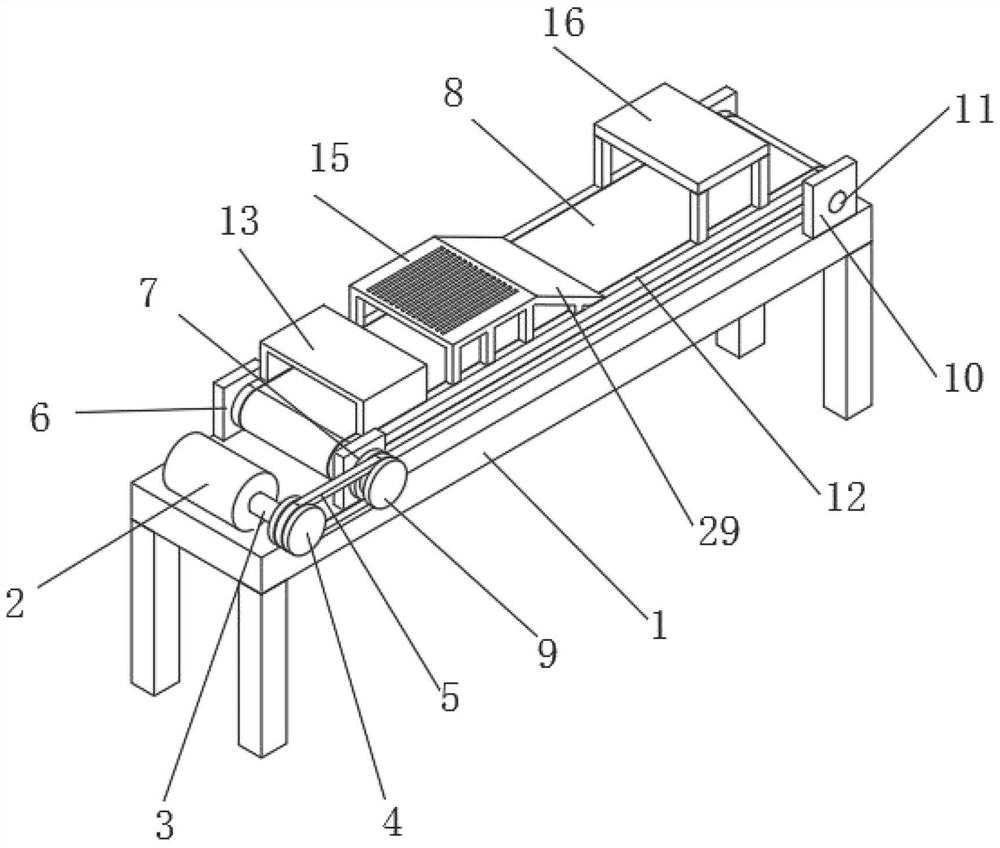

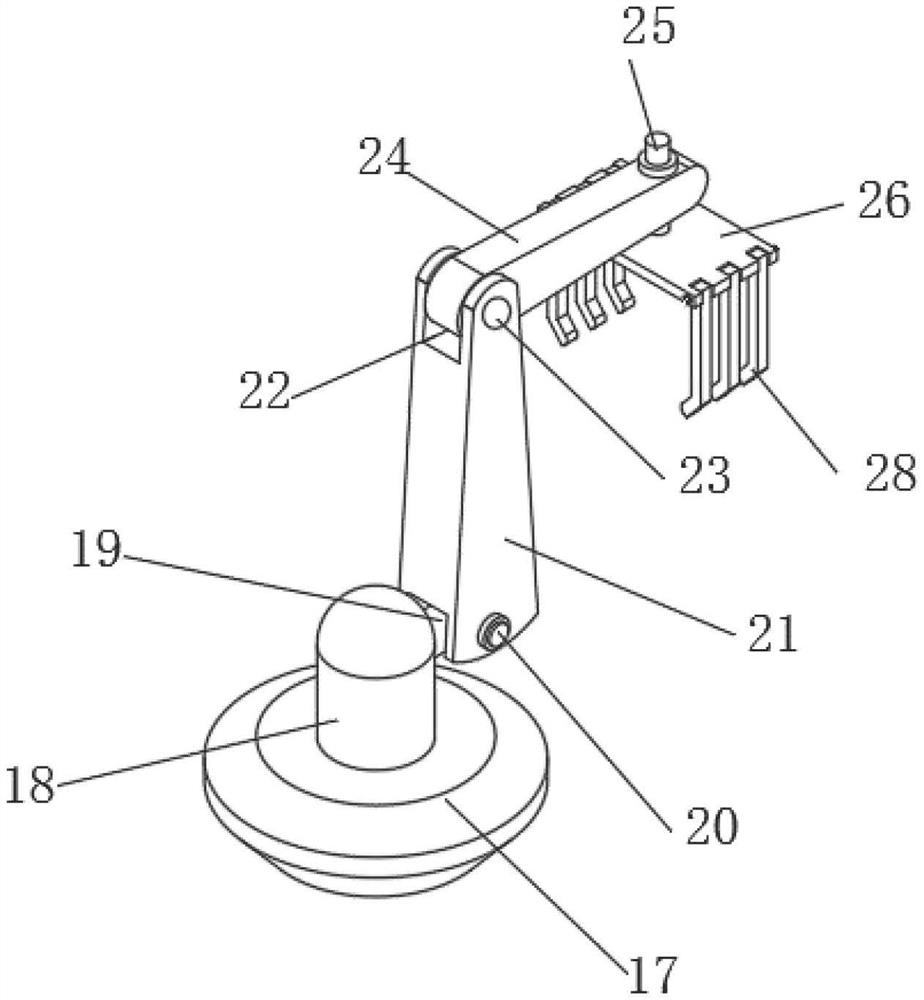

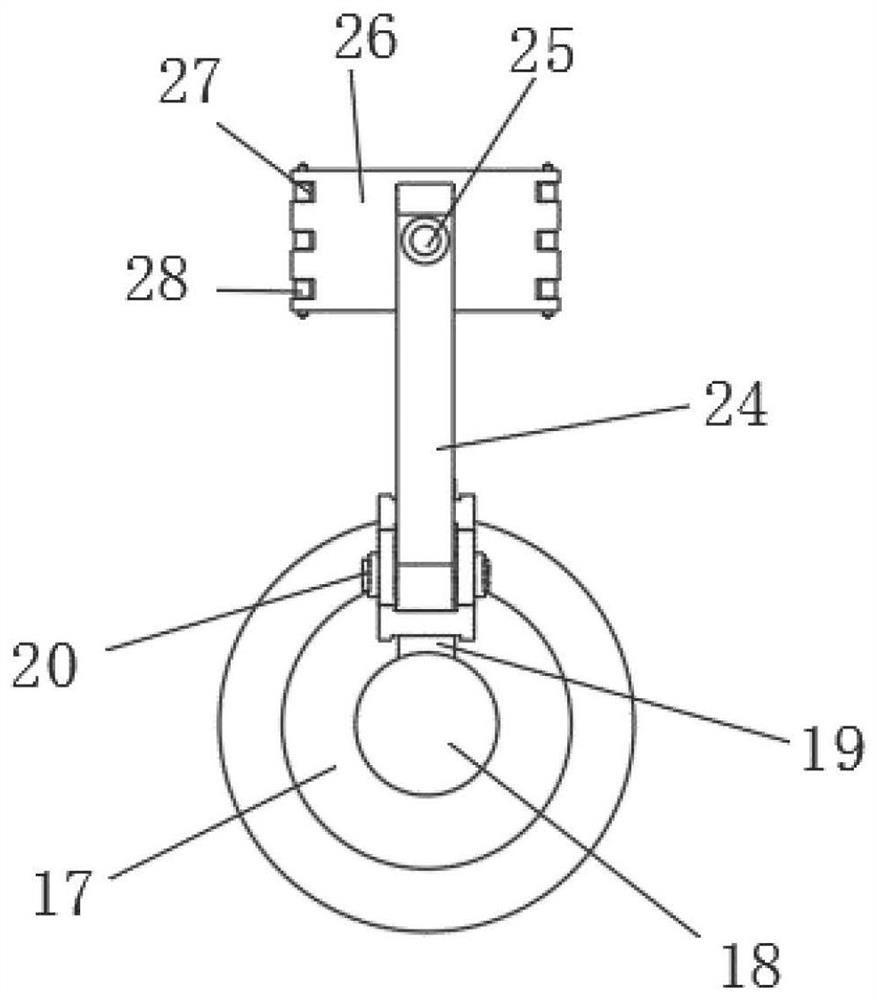

[0022] Example: see Figure 1-4 , the present invention provides a technical solution: an elevated cargo automatic grab and place loading and unloading robot, comprising a bracket 1, a motor 2 is arranged on the left side of the top of the bracket 1, and a rotating shaft 3 is fixedly connected to the front of the motor 2, and the rotation The outer ring of the shaft 3 is covered with a first sprocket 4, the outer ring of the first sprocket 4 is covered with a belt 5, and the side opposite to the left side of the top of the bracket 1 is provided with a side plate 6, and a connecting shaft is fixedly connected between the side plates 6 7. The outer ring of the connecting shaft 7 is covered with a conveyor belt 8, the front of the outer ring of the connecting shaft 7 is covered with a second sprocket 9, and the opposite side on the right side of the top of the bracket 1 is provided with a riser 10, and the stand of the riser 10 is fixedly connected There is a horizontal axis 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com