Environment-friendly anti-freezing concrete and preparation method thereof

A kind of concrete and environmental protection technology, applied in the field of concrete, can solve the problems of reducing the durability of concrete, reducing the strength of concrete, affecting the quality of construction and normal use, etc., and achieve the effect of suppressing micro-cracks, low porosity, high integrity and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

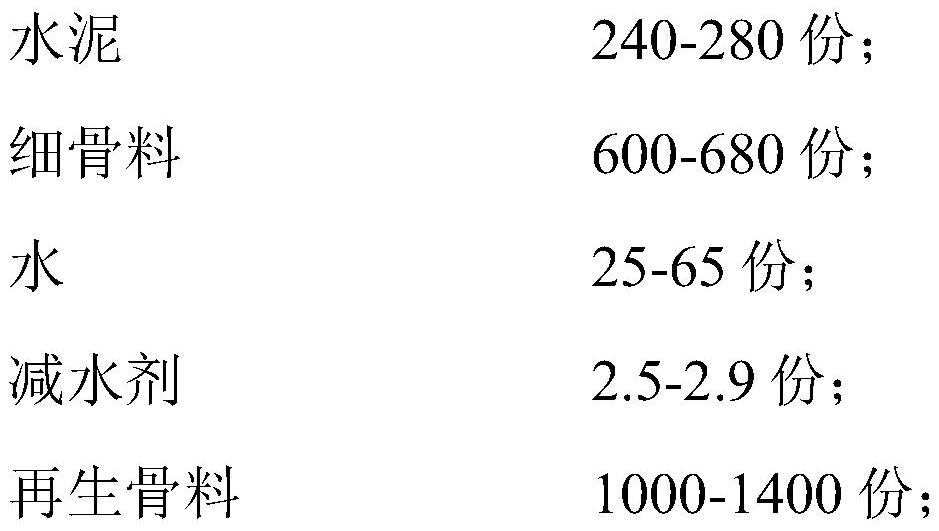

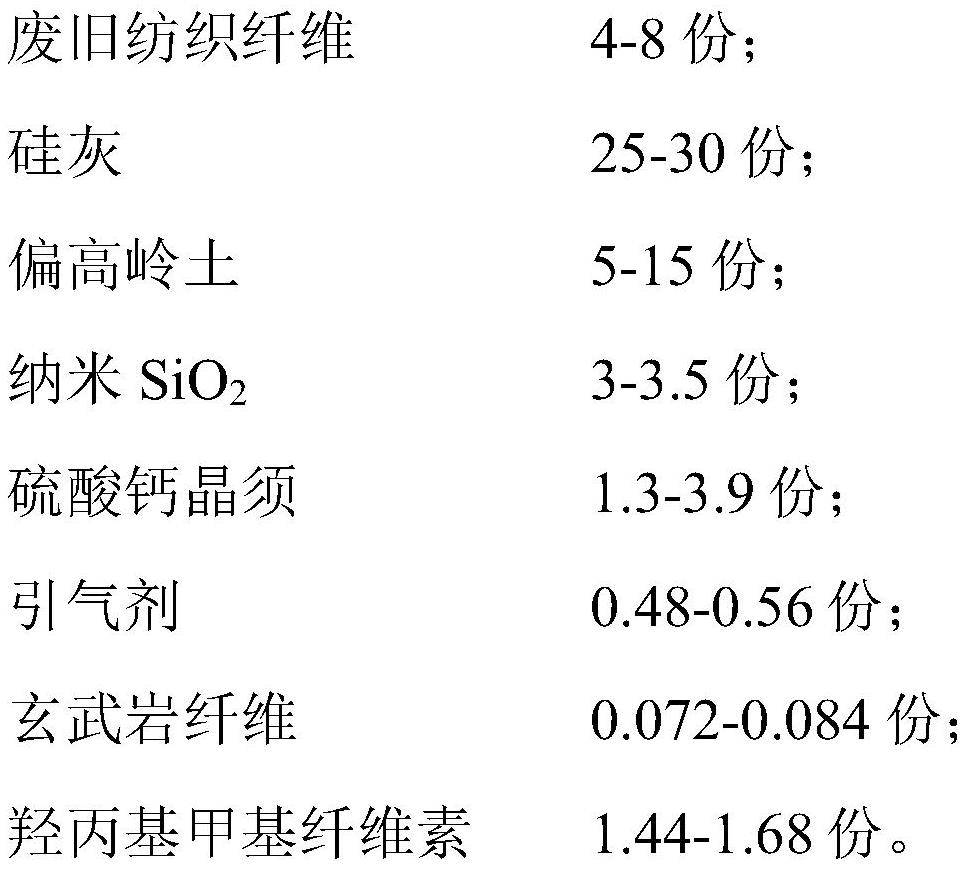

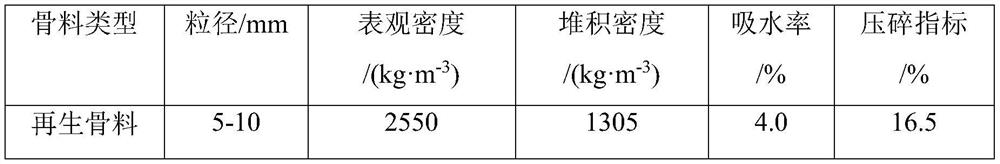

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of environment-friendly frost-resistant concrete, comprising the following steps:

[0057] S1. First mix cement, river sand, polycarboxylate superplasticizer, recycled aggregate, waste textile fiber, silica fume, metakaolin, and nano-SiO 2 , calcium sulfate whiskers, air-entraining agent, and basalt fiber were mixed and stirred for 2 minutes to obtain a premix; wherein, waste textile fibers included waste cotton fibers, waste polyester fibers, and waste glass fibers; nano-SiO 2 The particle diameter is 100-120nm;

[0058] S2. Then sprinkle the hydroxypropyl methylcellulose in the premix while stirring, stir for 5 minutes, and finally add water and mix and stir for 30 minutes to obtain environmentally friendly frost-resistant concrete.

Embodiment 2

[0060] A preparation method of environment-friendly frost-resistant concrete, comprising the following steps:

[0061] S1. First mix cement, river sand, polycarboxylate superplasticizer, recycled aggregate, waste textile fiber, silica fume, metakaolin, and nano-SiO 2 , calcium sulfate whiskers, air-entraining agent and basalt fiber were mixed and stirred for 3.5min to obtain a premix; wherein, waste textile fibers included waste cotton fibers, waste polyester fibers and waste glass fibers; nano-SiO 2 The particle diameter is 5-13nm;

[0062] S2. Then sprinkle the hydroxypropyl methylcellulose in the premix while stirring, stir for 7.5 minutes, and finally add water and mix and stir for 35 minutes to obtain environmentally friendly frost-resistant concrete.

Embodiment 3

[0064] A preparation method of environment-friendly frost-resistant concrete, comprising the following steps:

[0065] S1. First mix cement, river sand, polycarboxylate superplasticizer, recycled aggregate, waste textile fiber, silica fume, metakaolin, and nano-SiO 2 , calcium sulfate whiskers, air-entraining agent, and basalt fiber were mixed and stirred for 5 minutes to obtain a premix; wherein, waste textile fibers included waste cotton fibers, waste polyester fibers, and waste glass fibers; nano-SiO 2 The particle diameter is 70-90nm;

[0066] S2. Then sprinkle the hydroxypropyl methylcellulose in the premix while stirring, stir for 10 minutes, and finally add water and mix and stir for 40 minutes to obtain environmentally friendly frost-resistant concrete.

[0067] The consumption of each component in above-mentioned embodiment 1-3 is as shown in table 2:

[0068] Table 2 The usage scale of each component

[0069]

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com