Method for synthesizing polyolefin from alpha-olefin prepared from coal and product

A technology of polyolefins and olefins, which is applied in the field of continuous synthesis of high molecular weight and high branched polyolefins from coal-based α-olefins, which can solve the problems of lack of process methods and achieve high-efficiency preparation, excellent olefin polymerization ability, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

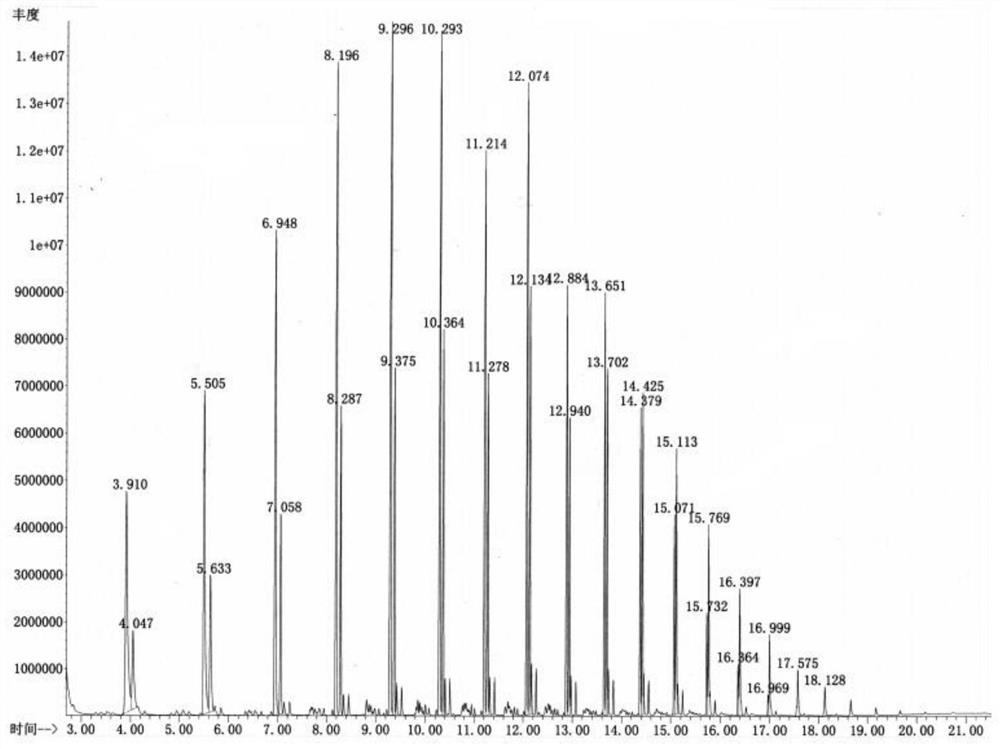

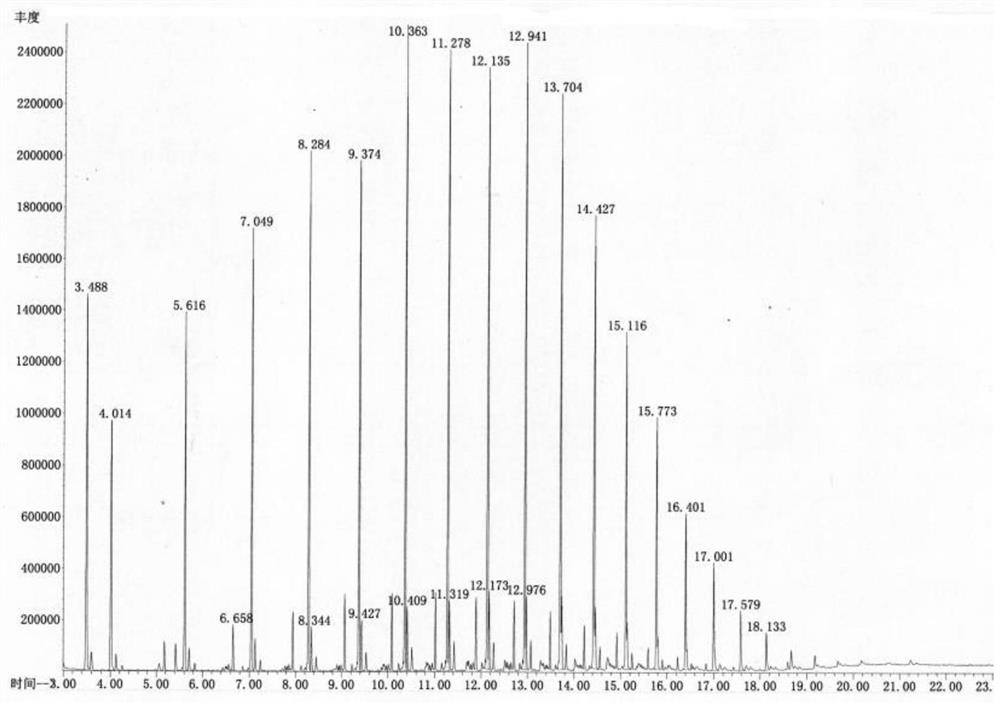

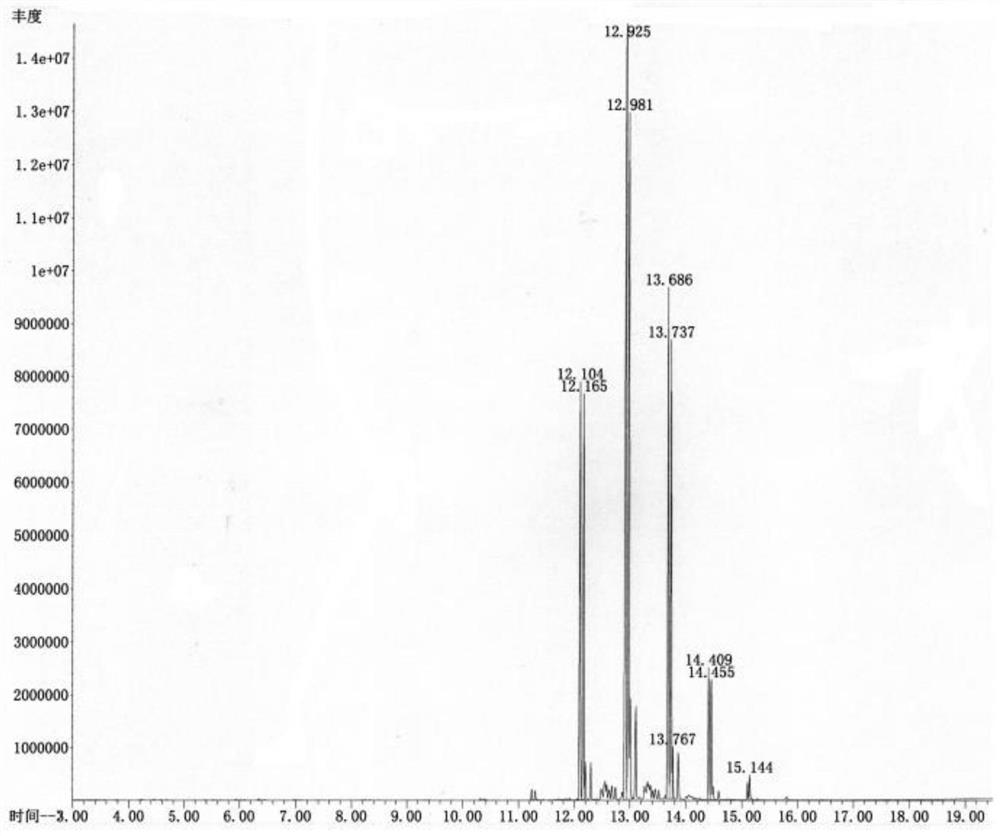

Image

Examples

Embodiment 1

[0103] Preparation of Ziegler-Natta catalyst:

[0104] (1) Under the protection of nitrogen, add 12mmol of triethylaluminum (1M n-hexane solution) 12mL dropwise to 21mmol of anhydrous magnesium chloride in tetrahydrofuran suspension (2g / 50mL) under an ice-water bath, return to room temperature after the dropwise addition, After heating to 70°C to activate the reaction for 3 hours, let it stand still, absorb the tetrahydrofuran solution in the upper layer, and obtain a slurry liquid; wherein, the molar ratio of the magnesium halide and the alkylaluminum compound is 1:0.57;

[0105] (2) Add 0.6mL tetrafluoropropanol (6.72mmol) and 0.7mL (5.99mmol) hexafluorobutanol mixture to the above slurry, and mix and react at 70°C for 3 hours; wherein, the moles of magnesium halide and fluoroalcohol The ratio is 1:0.6

[0106] (3) Then add 30mL TiCl 4 (273.6mmol, the molar ratio of magnesium halide and transition metal compound is 1:13), reflux at 80°C for 5 hours, let stand to cool to ro...

Embodiment 2

[0108] Except that the fluoroalcohol of embodiment 1 is replaced by 0.6mL tetrafluoropropanol (6.72mmol), 0.6mL octafluoropentanol (4.31mmol), 0.6mL hexafluoromethylpentanol (4.23mmol), other parameters and The conditions were all carried out according to Example 1 (21 mmol anhydrous magnesium chloride), and the Ziegler-Natta catalyst was prepared. Among them, the molar ratio of magnesium halide and fluoroalcohol is 1:0.72

Embodiment 3

[0110] Preparation of Ziegler-Natta catalyst:

[0111] (1) Under the protection of nitrogen, add 12mL of triethylaluminum (1M n-hexane solution) dropwise to 12mmol (2g / 50mL) of 21mmol of anhydrous magnesium chloride in n-hexane suspension in ice-water bath, return to room temperature after the dropwise addition , after being heated to 70°C for 3 hours to activate the reaction, let it stand, and after sucking off the n-hexane solution in the upper layer, wash it three times with 50mL of n-hexane (anhydrous treatment) respectively to obtain a slurry; wherein, the magnesium halide and the alkylaluminum compound The molar ratio is 1:0.57;

[0112] (2) Add 0.6mL trifluoroethanol (7.95mmol), 0.6mL hexafluoropentanol (4.54mmol), 0.6mL hexafluoroisopropanol (5.70mmol) mixed solution to the above slurry, mix and react at 70°C for 3 hours , wash the slurry with n-hexane (anhydrous treatment); wherein, the molar ratio of magnesium halide and fluoroalcohol is 1:0.86;

[0113] (3) Then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com