Azine-connected benzotrithienyl covalent organic framework material as well as preparation method and application thereof

A benzotrithienyl, covalent organic framework technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, inorganic chemistry, etc., can solve harsh conditions, covalent organic framework materials Poor crystal shape and other problems, to achieve the effect of strong applicability, easy promotion and utilization, and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

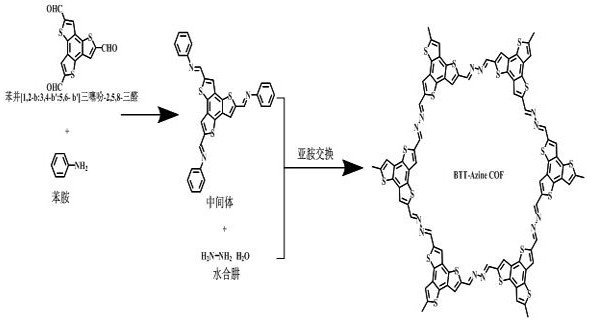

[0025] Add benzo[1,2-b:3,4-b′:5,6-b′]trithiophene-2,5,8-trialdehyde (BTT: 165 mg, 0.5 mmol) into the pressure bottle, Aniline (230 μL, 2.5 mmol), 1,4-dioxane (15 mL) and glacial acetic acid (0.15 mL) were placed in an oil bath at 120°C under reflux for 12 hours. Then a yellow solid was precipitated in ice methanol, and the solid was collected by suction filtration, washed three times with methanol, and dried under vacuum at 60°C overnight to obtain an intermediate.

[0026] Put the intermediate (33.1 mg, 0.06 mmol), hydrazine hydrate (5 μL, 0.1 mmol) and 1 mL o-dichlorobenzene / 1,4-dioxane (volume ratio 1:1) mixed solution in a Pyrex tube , sonicate for 10 minutes to obtain a uniform dispersion, then add acetic acid (0.1 mL, 6M). Freeze-thaw cycle degassing in a liquid nitrogen bath for 3 times, and react at 120 °C for 3 days after vacuum sealing, cool to room temperature, collect the solid by suction filtration, wash with methanol, dichloromethane and acetone three times resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com