Preparation method of snow-melting agent and prepared snow-melting agent

A snow-melting agent and mixture technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of chlorine salt-based snow-melting agents that are not environmentally friendly, high in cost, and complicated in the preparation method of snow-melting agents, and achieve good protection and fertilization. The effect of high stability, low freezing point and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

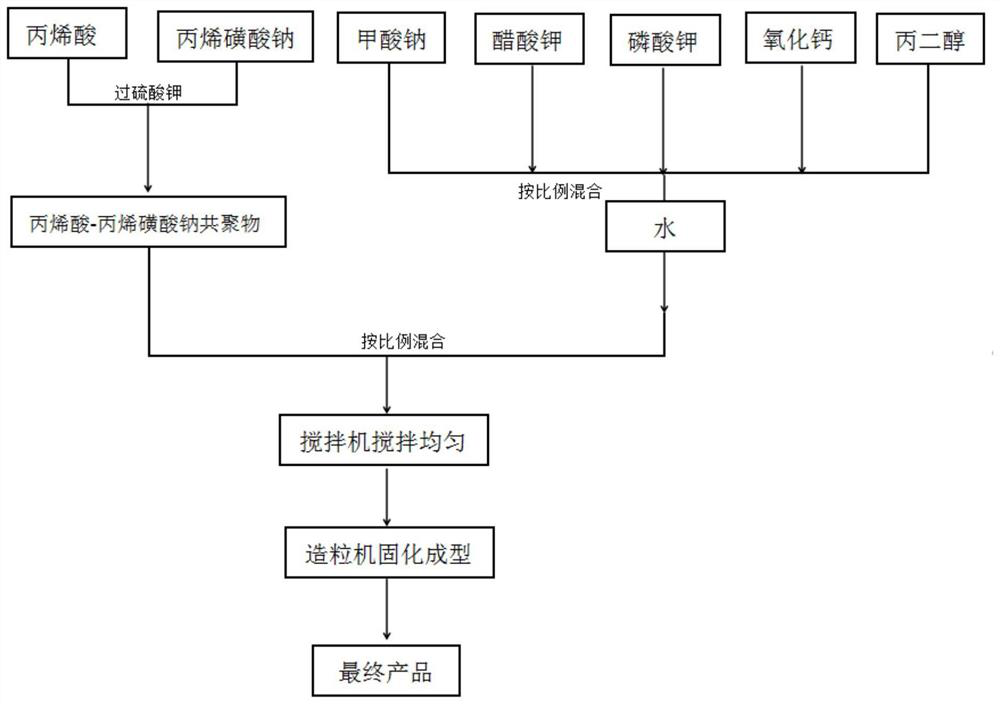

[0043] The present embodiment provides a kind of preparation method of deicing agent, specifically implement according to the following steps:

[0044] Step 1, synthesis of acrylic acid and sodium propylene sulfonate copolymer: According to the mass ratio of 2:2:1, first add 8g of water, 8g of acrylic acid, and 4g of sodium propylene sulfonate, stir to dissolve, heat to 70°C, and dissolve 0.6g of The aqueous solution of potassium sulfate initiator was added dropwise into the bottle, and reacted at constant temperature for 4 hours to obtain a colorless or light yellow transparent viscous liquid;

[0045] Step 2, adding the following mass percentage raw materials into the mixer for mixing and stirring: 30% sodium formate, 20% potassium acetate, 9% potassium phosphate, 9% calcium oxide, 12% propylene glycol and 10% water to obtain the primary mixture;

[0046] Step 3, continue to add 10% by mass of acrylic acid and sodium propylene sulfonate copolymer to the primary mixture, and ...

Embodiment 2

[0049] The present embodiment provides a kind of preparation method of deicing agent, specifically implement according to the following steps:

[0050] Step 1, synthesis of acrylic acid and sodium propylene sulfonate copolymer: According to the mass ratio of 2:2:1, first add 8g of water, 8g of acrylic acid, and 4g of sodium propylene sulfonate, stir to dissolve, heat to 70°C, and dissolve 0.6g of The aqueous solution of potassium sulfate initiator was added dropwise into the bottle, and reacted at constant temperature for 4 hours to obtain a colorless or light yellow transparent viscous liquid;

[0051] Step 2, adding the following mass percentage raw materials into the mixer for mixing and stirring: 35% sodium formate, 15% potassium acetate, 10% potassium phosphate, 8% calcium oxide, 13% propylene glycol and 8% water to obtain the primary mixture;

[0052] Step 3, continue to add 10% by mass of acrylic acid and sodium propylene sulfonate copolymer to the primary mixture, and ...

Embodiment 3

[0055] The present embodiment provides a kind of preparation method of deicing agent, specifically implement according to the following steps:

[0056] Step 1, synthesis of acrylic acid and sodium propylene sulfonate copolymer: According to the mass ratio of 2:2:1, first add 8g of water, 8g of acrylic acid, and 4g of sodium propylene sulfonate, stir to dissolve, heat to 70°C, and dissolve 0.6g of The aqueous solution of potassium sulfate initiator was added dropwise into the bottle, and reacted at constant temperature for 4 hours to obtain a colorless or light yellow transparent viscous liquid;

[0057] Step 2, adding the following mass percentage raw materials into the mixer for mixing and stirring: 40% sodium formate, 10% potassium acetate, 8% potassium phosphate, 10% calcium oxide, 13% propylene glycol and 9% water to obtain the primary mixture;

[0058] Step 3, continue to add 10% by mass of acrylic acid and sodium propylene sulfonate copolymer to the primary mixture, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com