Movable tensile shear stress rock breaking equipment system

A shear stress and mobile technology, applied in the field of mechanical rock breaking, can solve the problems of not resisting tensile shear, etc., and achieve the effects of being easy to master, protecting the environment, and solving low energy utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

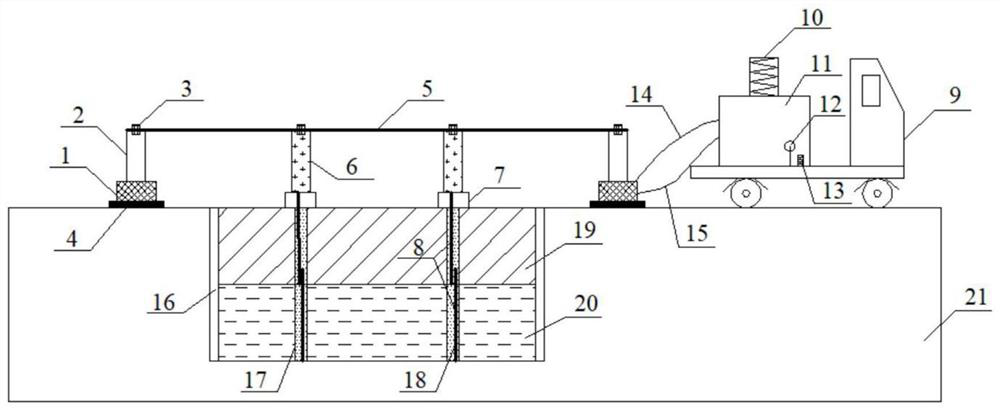

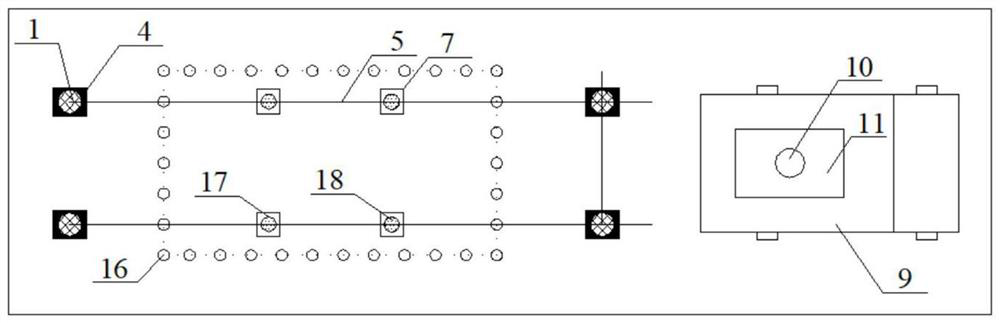

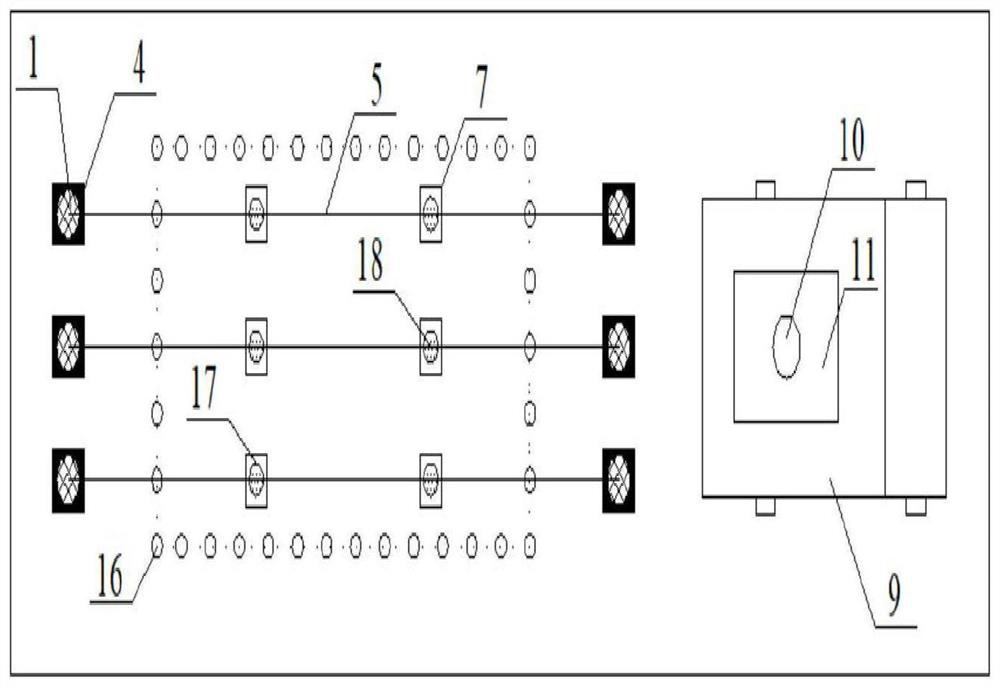

[0026] In order to better describe the present invention, a mobile tension-shear stress rock breaking equipment system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Depend on figure 1 Shown is a schematic diagram of a longitudinal section of a mobile tension-shear stress rock breaking equipment system of the present invention combined with figure 2 , image 3 It can be seen that a mobile tension-shear stress rock-breaking equipment system of the present invention is composed of a hydraulic power mechanism and a pulling-out rock-breaking mechanism connected by an oil delivery pipeline 14 and an oil return pipeline 1 .

[0028] Described hydraulic power mechanism comprises movable power car 9, the hydraulic oil tank 11 that is assembled on the power car 9, and hydraulic oil tank 11 is provided with driving motor 10, pressure gauge 12, the manipulator 13 that controls hydraulic oil tank 11 to send oil....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com