A nanoporous al/au/mno 2 Electrode materials and supercapacitors prepared therefrom

A supercapacitor and nanoporous technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor adhesion and no discovery, and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

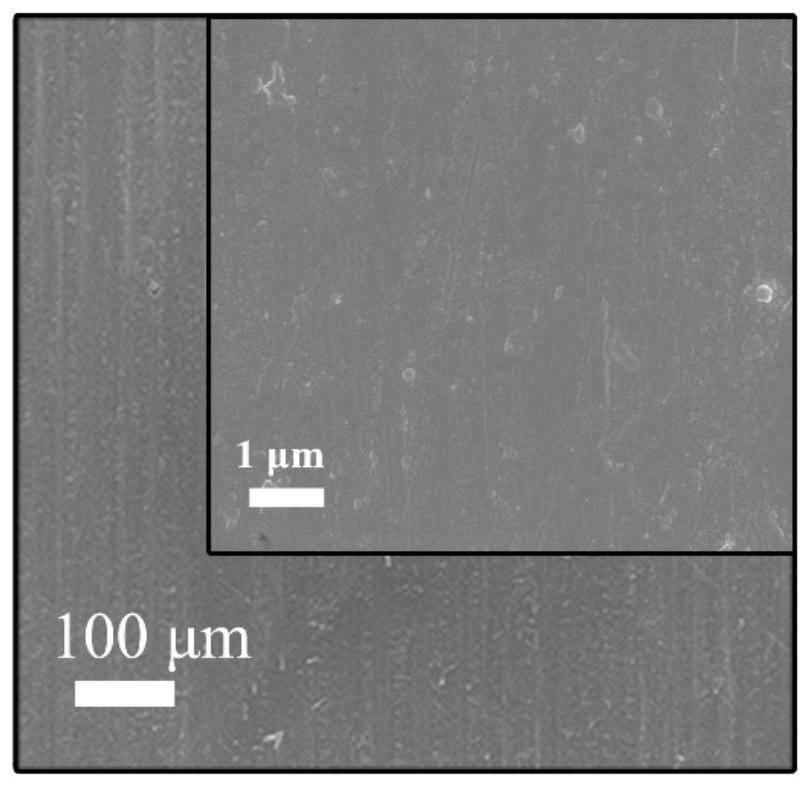

[0039] (1) First cut the original aluminum foil into an area of 2.0×1.5cm 2 Then immerse these flakes of aluminum foil in acetone and alcohol solution to remove the grease on the surface, then use alcohol and deionized water to fully wash the aluminum foil, rinse it, and dry it for later use.

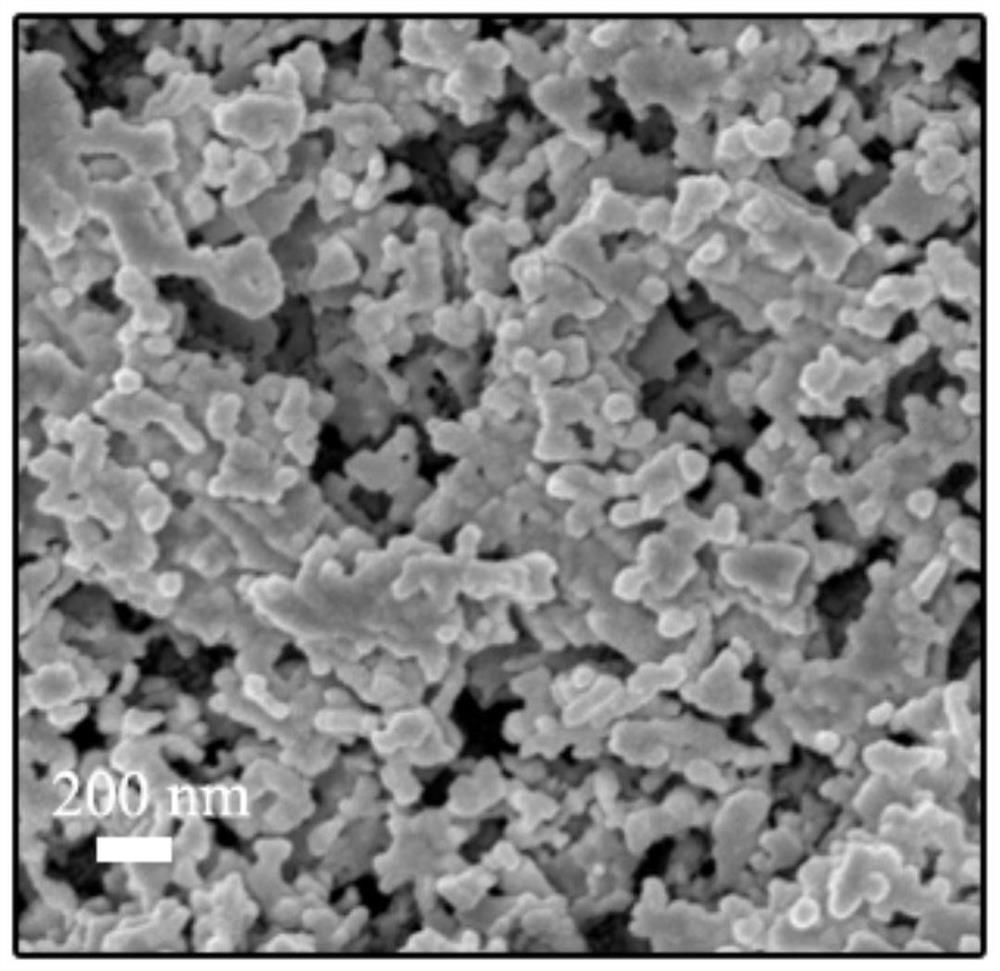

[0040] (2) Spray-plating on the aluminum foil for 5 minutes using ion plating equipment, forming an ultra-thin gold layer on the surface to obtain an Al / Au current collector. MnO 2 It is obtained by direct deposition on Al / Au current collector by electrochemical deposition three-electrode system. The deposition solution is 0.1mol / L Mn(CH 3 COO) 2 4H 2 O and 0.1mol / L Na 2 SO 4 mixture. The deposition is constant voltage deposition, the deposition voltage is +0.8V, and the deposition time is 400s. After deposition, the resulting Al / Au / MnO 2 The electrodes were fully washed with deionized water to remove residual electrolyte and dried at 80 °C for 30 min. The prepared electrode...

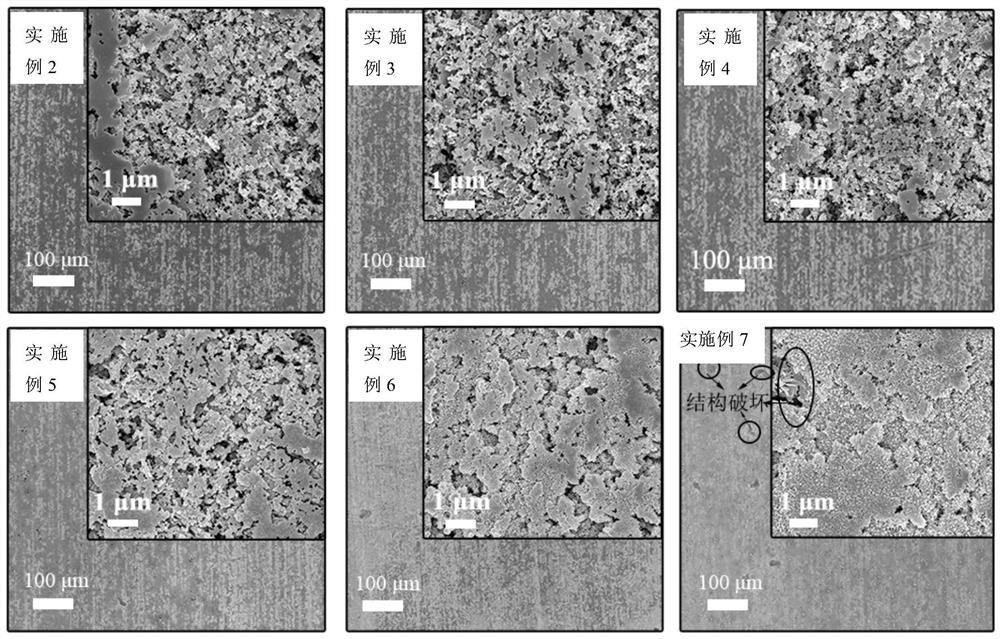

Embodiment 2

[0043] (1) First cut the original aluminum foil into an area of 2.0×1.5cm 2 The size of the sheet, and then dip these sheets of aluminum foil in acetone and alcohol solution to degrease the surface. Subsequently, the aluminum foil was immersed in a mixed acid solution with a molar ratio of hydrochloric acid and sulfuric acid of 1:1 for corrosion, and the corrosion time was 10s. Finally, the corroded aluminum foil is fully washed with alcohol and deionized water to remove residual acid, and dried for later use.

[0044] (2) Spray-plating on the corroded aluminum foil for 5 minutes by ion plating equipment, forming an ultra-thin gold layer on the surface to obtain an Al / Au current collector. MnO 2 It is obtained by direct deposition on Al / Au current collector by electrochemical deposition three-electrode system. The deposition solution is 0.1mol / L Mn(CH 3 COO) 2 4H 2 O and 0.1mol / L Na 2 SO 4 mixture. The deposition is constant voltage deposition, the deposition voltag...

Embodiment 3

[0047] (1) First cut the original aluminum foil into an area of 2.0×1.5cm 2 The size of the sheet, and then dip these sheets of aluminum foil in acetone and alcohol solution to degrease the surface. Subsequently, the aluminum foil was immersed in a mixed acid solution with a molar ratio of hydrochloric acid and sulfuric acid of 1:1 for corrosion, and the corrosion time was 20s. Finally, the corroded aluminum foil is fully washed with alcohol and deionized water to remove residual acid, and dried for later use.

[0048] (2) Spray-plating on the corroded aluminum foil for 5 minutes by ion plating equipment, forming an ultra-thin gold layer on the surface to obtain an Al / Au current collector. MnO 2 It is obtained by direct deposition on Al / Au current collector by electrochemical deposition three-electrode system. The deposition solution is 0.1mol / L Mn(CH 3 COO) 2 4H 2 O and 0.1mol / L Na 2 SO 4 mixture. The deposition is constant voltage deposition, the deposition voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com