Ultraviolet LED and manufacturing method thereof

A stress and balance layer technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of expanding and increasing the demand for ultraviolet LEDs, so as to improve the radiation recombination efficiency, reduce the quantum confinement Stark effect, reduce the The effect of the polarization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

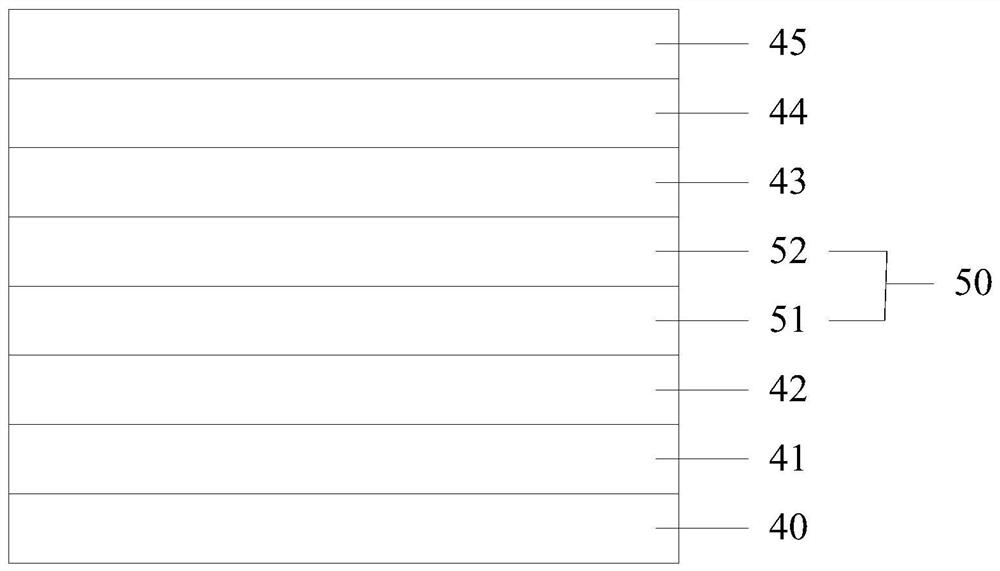

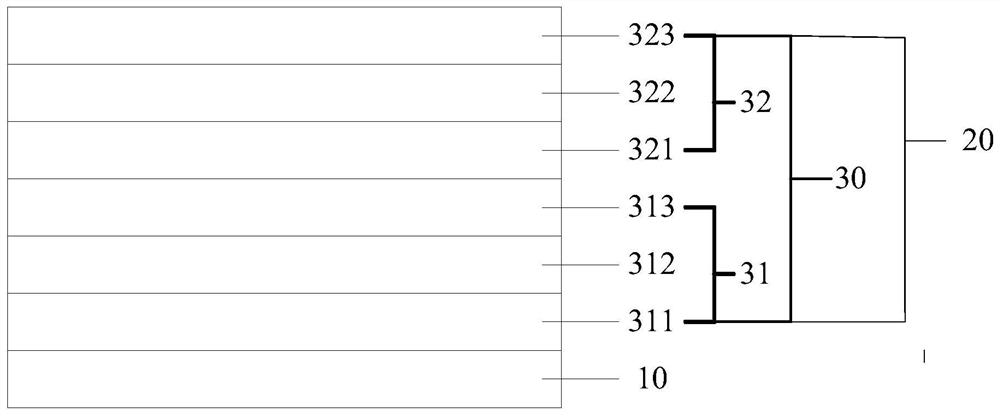

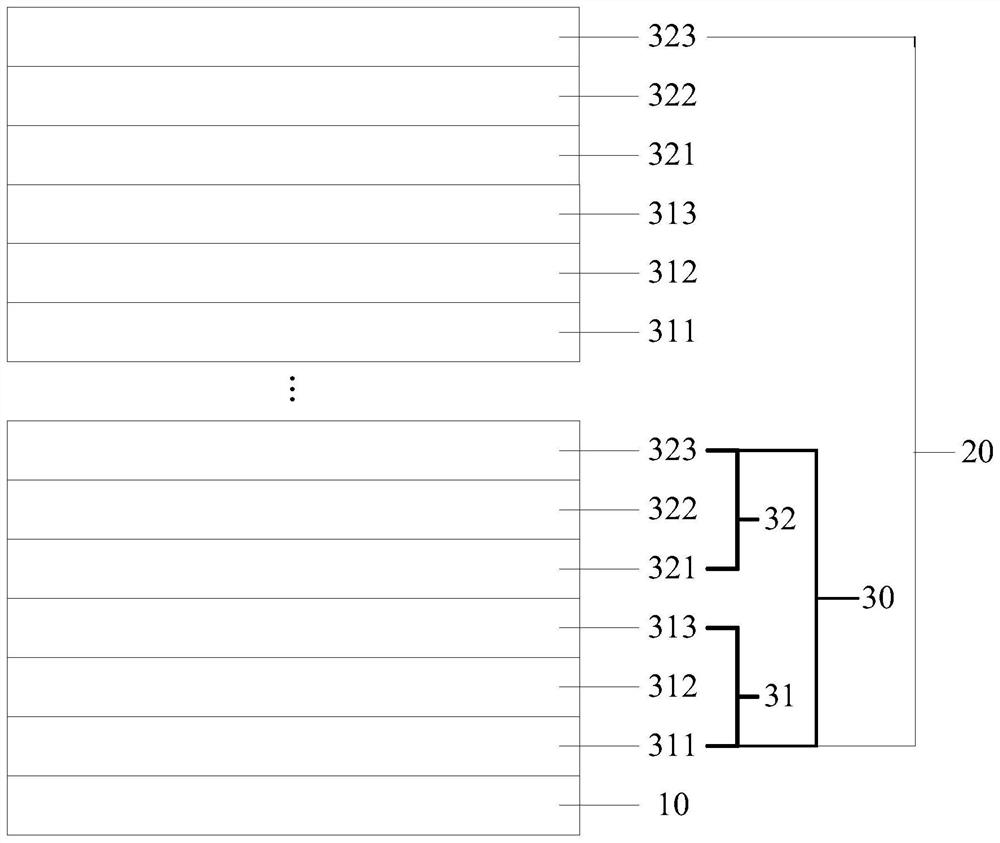

[0070] Specifically, such as Figure 5 As shown, the ultraviolet LEDs include: substrate 60, AlN buffer layer 61, Aln / AlGaN stress release layer 62, N-AlGaN electron supply layer 63, light-emitting layer 70, AlGan barrier layer 64, P-AlGa hole supply layer 65 The Gan ohmic contact layer 66, wherein the light-emitting layer 70 includes 2 to 12 laminated units 71, and the first stress balance layer 712 in each of the lamination units 71 is in. x GA 1-x N stress balance layer, the second stress balance layer 715 is in x GA 1-x N-stress balancing layer, the first quantum layer 711 is Al a GA 1-a N quantum barrier layer, the second quantum barrier 713 is Al a GA 1-a N quantum barrier layer, the first quantum well layer 714 is Al b In c GA 1-b-c N quantum well layer, the second quantum well layer 716 is Al b In c GA 1-b-c N quantum well layer.

Embodiment 2

[0072] Specifically, such as Figure 6 As shown, the ultraviolet LEDs include: substrate 80, AlN buffer layer 81, Aln / AlGaN stress release layer 82, N-AlGaN electron supply layer 83, light emitting layer 90, AlGaN barrier layer 84, P-AlGan hole supply layer 85 The GaN ohmic contact layer 86, wherein the light-emitting layer 90 includes 2 to 12 laminated units 91, and the first stress balancing layer 912 in each of the laminate unit 91 is a GaN stress balancing layer, a second stress balance layer. 915 is the GaN stress balance layer, the first quantum barrier layer 911 is Al a GA 1-a N quantum barrier layer, the second quantum barrier 913 is Al a GA 1-a N quantum barrier layer, the first quantum well layer 914 is Al b In c GA 1-b-c N quantum well layer, the second quantum well layer 916 is Al b In c GA 1-b-c N quantum well layer.

[0073]It should be noted that in the ultraviolet LED provided in Embodiments One and Example 2, the lattice constant of the first stress balance layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com