Fruit wine production crusher

A crusher and fruit wine technology, applied in presses, manufacturing tools, grain processing, etc., can solve problems such as inability to separate self-flowing juice, poor fruit crushing efficiency and crushing quality, and decline in fruit wine quality, so as to improve crushing efficiency and crushing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

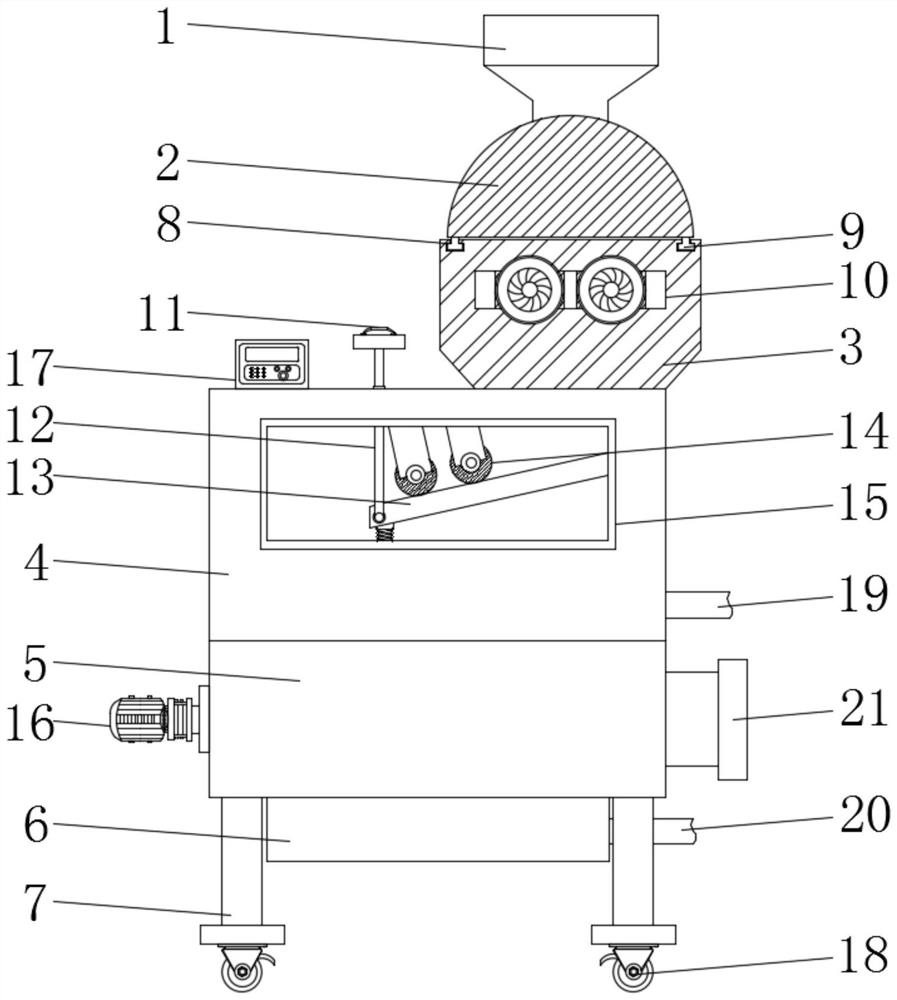

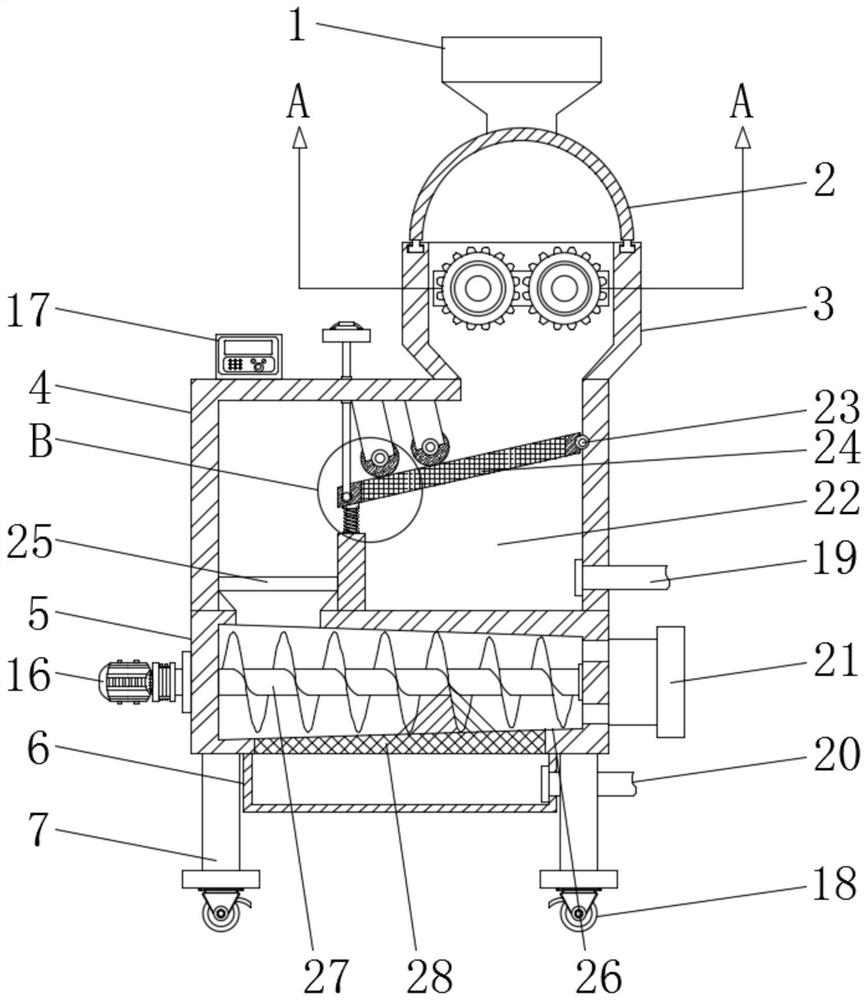

[0042] Example 1, a fruit wine production crusher, including a broken bun 3, a filter juice 4, and a juicard bin 5, broken cartridge 3 bottom communication filter juice 4 inner cavity, and cut off the broken bun 3 or fixed mounting The bin juice box 22 of the juice 4, and the self-sufficient juice box 22 is provided with a filter plate 13 between the broken coatings 3, and the filter plate 13 is mounted on the side wall of the filter juice 4 in the filter juice 4 by the first rotating shaft 23. The filter plate 13 is lowered by a plurality of spring 44, and a screen 24 is attached to the filter plate 13 in the center of the filter plate 13, and the filter juice 4 is mounted on one side of the lower body 25, and The lower hopper 25 bottom communication juice 5 inner cavity, the juice bun 5 is fixedly mounted, and press spiral 27 is mounted in the spiral tube 26, and the press spiral 27 is connected to a servo located outside the juice bin 5. The motor 16 outputs, which can be separ...

Embodiment 2

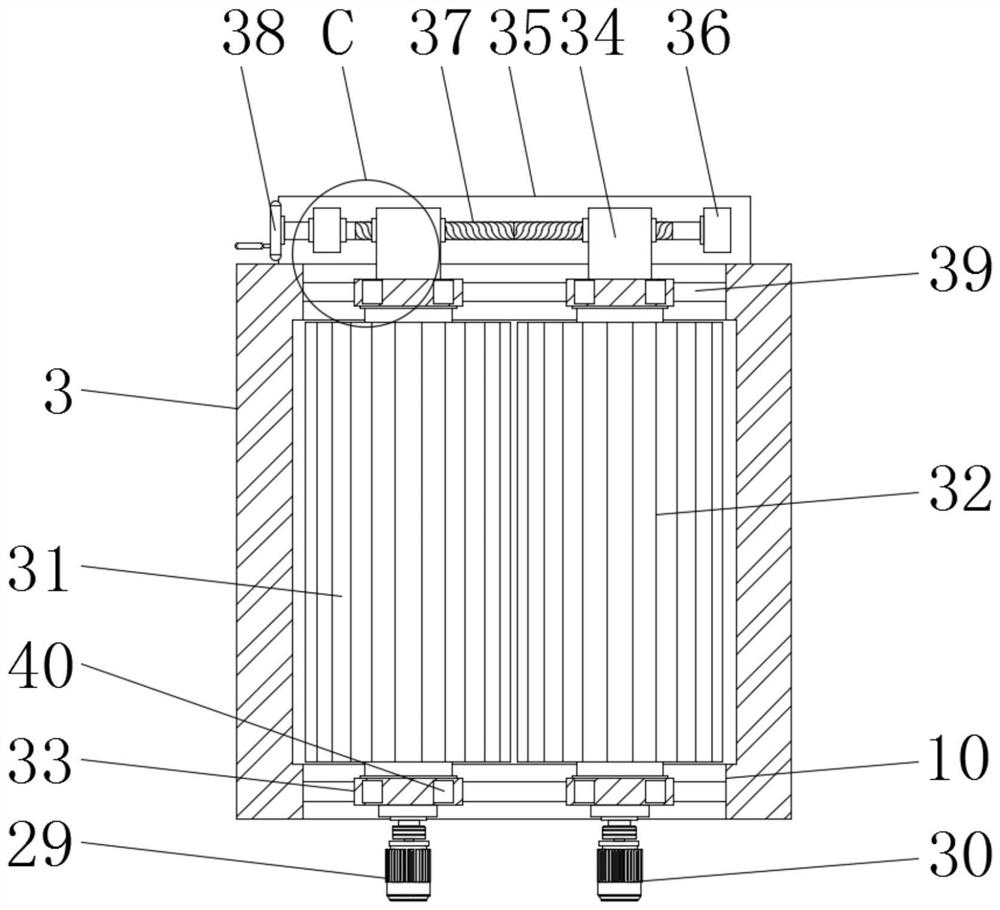

[0043] In an Example 2, the side of the broken bun 3 is configured to open an adjustment window 10, and the adjustment window 10 is symmetrically opened, and the moving rail 39 is opened, and the movement rail 39 is mounted in the mounting plate 33 on the upper and lower ends of the mounting plate 40. The first broken roller 31 and the second broken roller 32 are respectively mounted between the four mounting plates 33, and the first broken roller 31 is connected to the first broken down motor 29, and the second broken roller 32 is connected to the second broken motor 30 output. The effect of crushing the fruits in the broken crushing roller 31 and the second broken roller 32 are used in the broken crux 3.

Embodiment 3

[0044] Example I. Example 3. The side surface of the broken bun 3 is fixedly mounted and attached to the top of the adjustment window 10, and the top of the support plate 35 is symmetrically mounted having a bearing 36, and the shaft 46 is mounted in the bearing 36, and the rotating shaft 46 is fixedly connected to adjustment The hand wheel 38, and the center of the shaft 46 is attached to the bidirectional threaded rod 37, and the two side mounting plates 33 are respectively fixed, and the connection block 34 is fixed, and there is a nut 45 inside the two connecting blocks 34. Two-way threaded rod 37 two The end is mounted in two nuts 45, which enables the adjustment of the spacing between the first broken roller 31 and the second broken roller 32, to apply to the crushing requirements of different kinds of fruit, improved fruit crushing efficiency and crushing quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com