A kind of microwave solidification method and device of water glass sand extruded microhammer 3D printing

A three-dimensional printing, water glass sand technology, applied in casting molding equipment, casting mold components, manufacturing tools, etc., can solve the problems of large use of resin sand, toxicity of resin binder, uneven mixing of binder and molding sand, etc. , to achieve the effect of low material usage, good quality of recycled sand, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

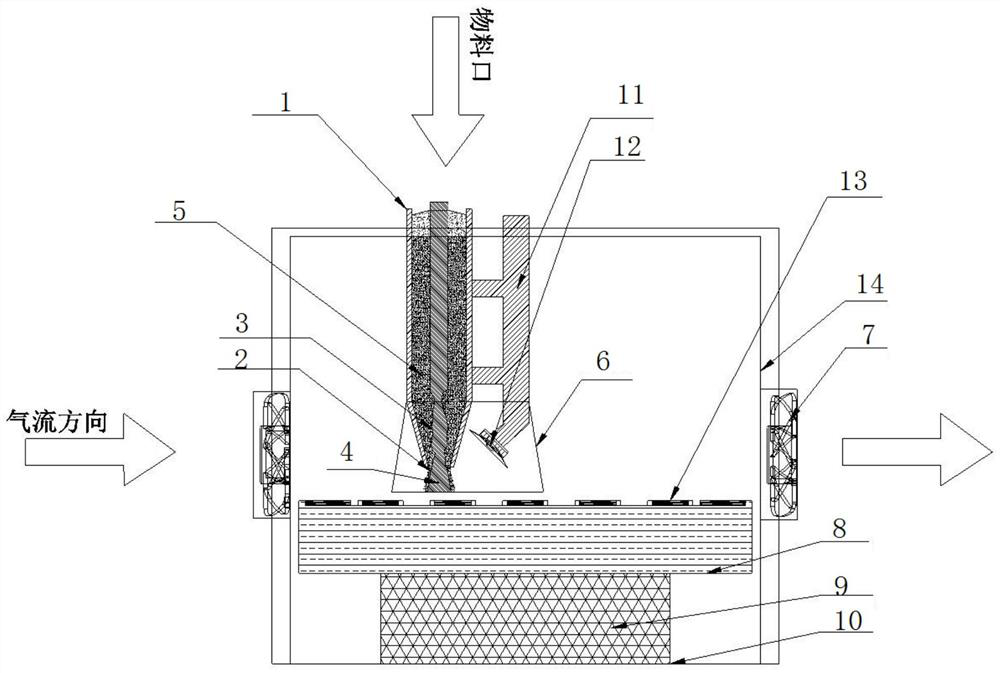

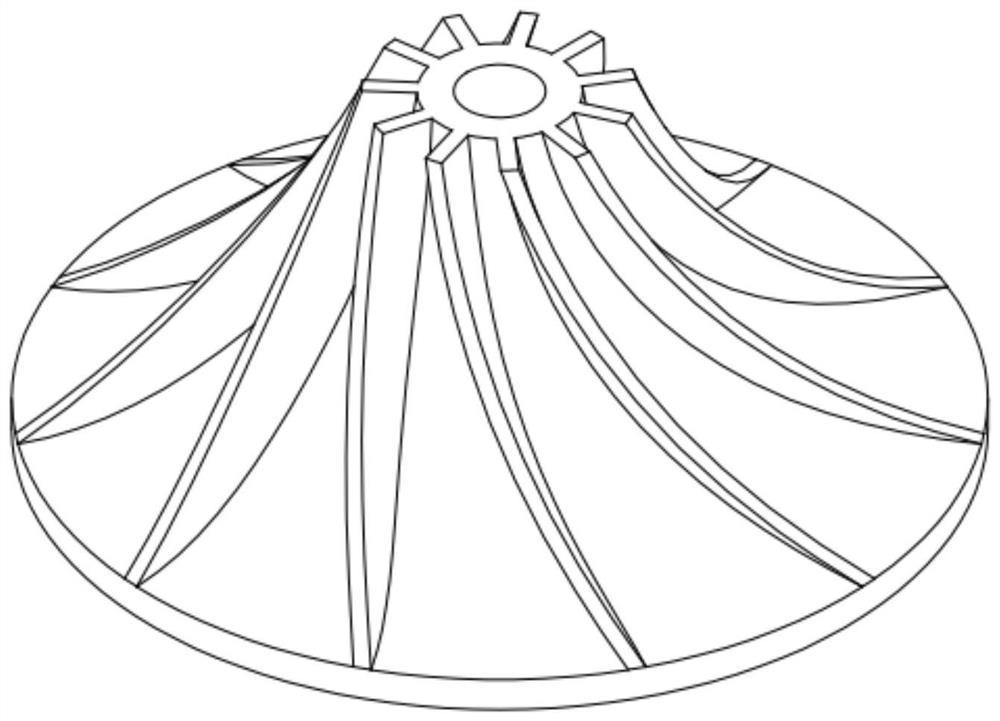

[0044]Using the apparatus and method of the present invention to form a supercharged turbine blade, blade height 45mm, top maximum outer ring 9mm, bottom diameter 48mm, hole 5mm, Figure 2 Is an embodiment of the present invention in the water glass sand supercharged turbine blade sand shape structure schematic diagram.

[0045] The specific process is as follows:

[0046] 1. According to the contour size of the water glass sand core to be formed, select the part drawings that need to be printed through the operation on the terminal.

[0047] 2. Mixed water glass binder, anti-moisture absorbent, absorbent and flow promoter, sand particles composed of mixed slurry 5.

[0048] 3, the water glass binder, anti-moisture absorbent, absorbent and flow promoter, sand particles composed of mixed abrasives through the rubber nozzle 2 extruded onto the workbench, concave and convex guide column 3 at the lower end of the micro-hammer head 4 up and down slight hammer mixing slurry 5 to form the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com