Wet viscous sludge pretreatment method suitable for heat treatment technology

A pretreatment and sludge technology, applied in the field of resources and environment, can solve problems such as wall corrosion, obvious agglomeration, manual cleaning, etc., and achieve the effect of enhancing plasticity and integrity, increasing specific surface area, and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

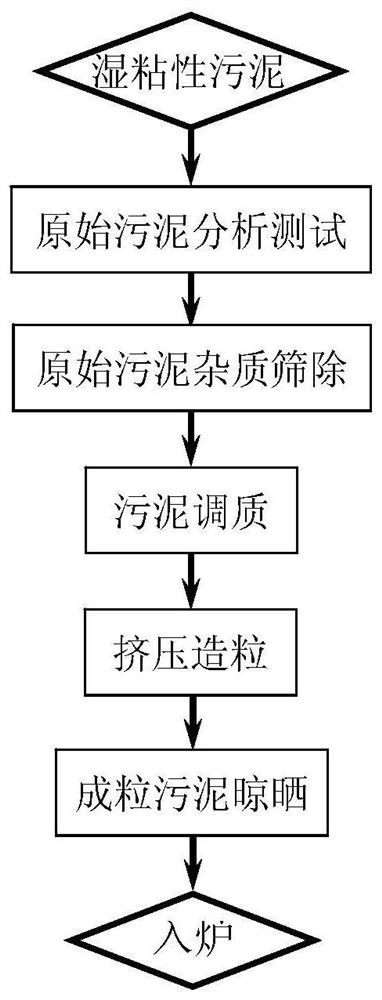

Method used

Image

Examples

Embodiment 1

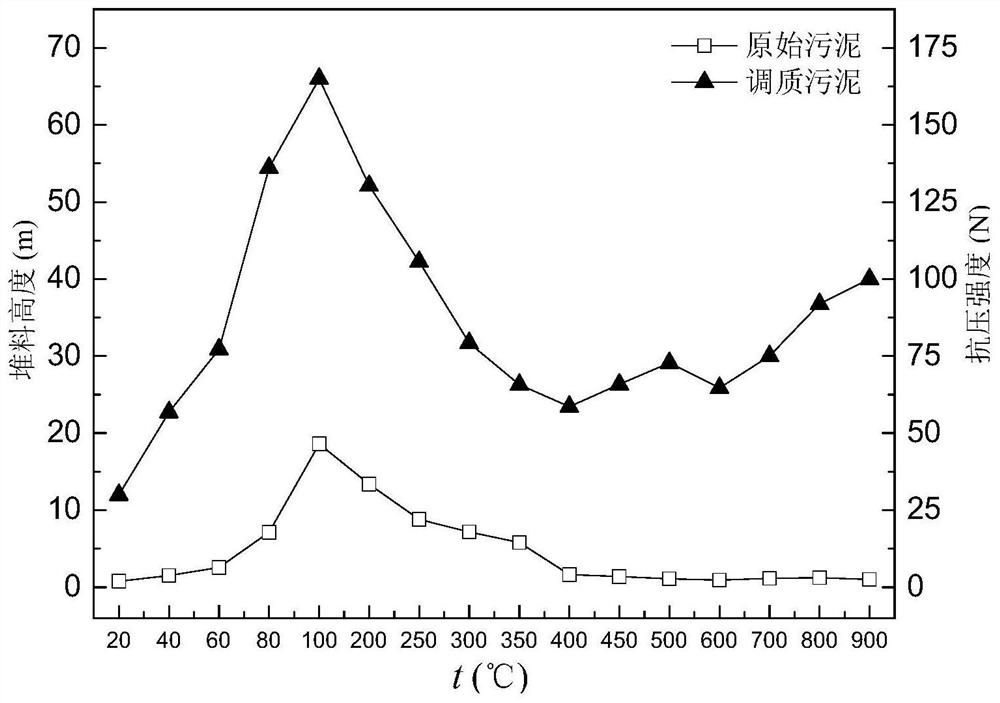

[0035]Example 1 The oily sludge produced by an oil production plant is pretreated. The described wet viscous sludge pretreatment method applicable to heat treatment technology comprises the following steps:

[0036] Step 1: Raw sludge analysis test. The composition of the raw sludge was analyzed and tested, including moisture content, organic matter content, inorganic solid phase content and other indicators, the results are shown in Table 1; according to the moisture content value, the raw sludge belongs to medium humidity (moisture content 40% ~ 50%) type.

[0037] Table 1 Raw sludge composition

[0038]

[0039] Step 2: Screen out the impurities in the original sludge. Select appropriate screening machinery and methods to screen out the large impurities with a particle size of 2 cm or more in the raw sludge in step 1.

[0040] Step 3: Conditioning of sludge. Select appropriate conveying and mixing machinery and methods, add a certain proportion of conditioner to the...

Embodiment 2

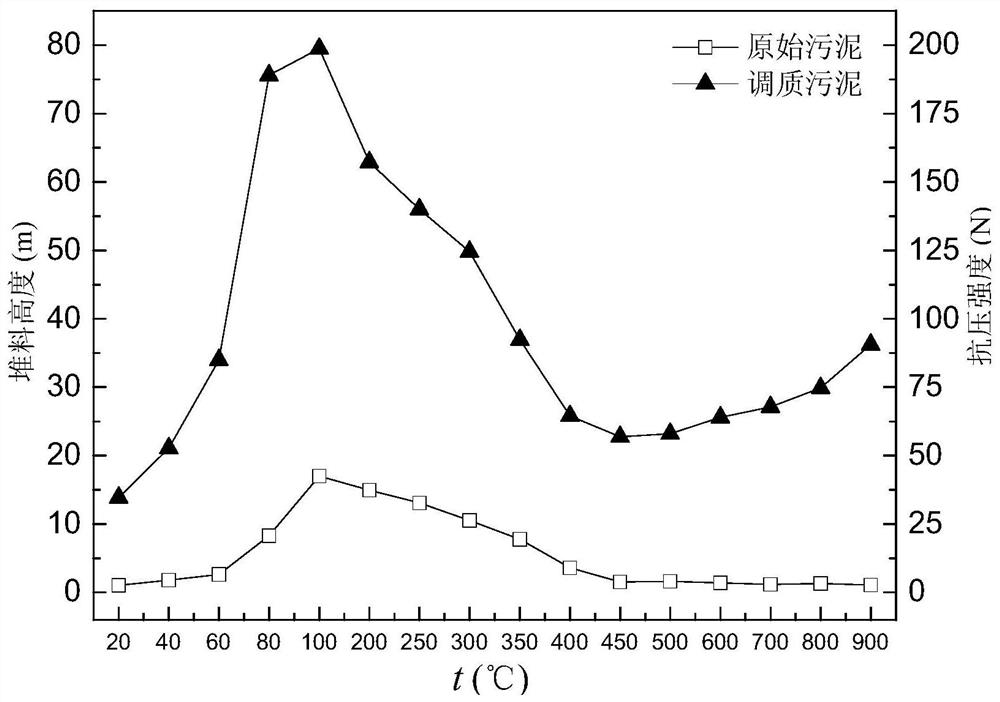

[0044] Example 2 The oily sludge produced by an oil production plant is pretreated. The described wet viscous sludge pretreatment method applicable to heat treatment technology comprises the following steps:

[0045] Step 1: Raw sludge analysis test. The composition of raw sludge was analyzed and tested, including moisture content, organic matter content, inorganic solid phase content and other indicators, the results are shown in Table 2; according to the moisture content value, the raw sludge belongs to low humidity (moisture content 35% ~ 40% %)type.

[0046] Table 2 Raw sludge composition

[0047]

[0048] Step 2: Screen out the impurities in the original sludge. Select appropriate screening machinery and methods to screen out the large impurities with a particle size of 2 cm or more in the raw sludge in step 1.

[0049] Step 3: Conditioning of sludge. Select appropriate conveying and mixing machinery and methods, add a certain proportion of conditioner to the raw ...

Embodiment 3

[0053] Example 3 The oily sludge produced by an oil production plant was pretreated.

[0054] The described wet viscous sludge pretreatment method applicable to heat treatment technology comprises the following steps:

[0055] Step 1: Raw sludge analysis test. The composition of the raw sludge was analyzed and tested, including moisture content, organic matter content, inorganic solid phase content and other indicators, the results are shown in Table 3; according to the moisture content value, the raw sludge belongs to high humidity (moisture content 50% ~ 55%) type.

[0056] Table 3 Raw sludge composition

[0057]

[0058] Step 2: Screen out the impurities in the original sludge. Select appropriate screening machinery and methods to screen out the large impurities with a particle size of 2 cm or more in the raw sludge in step 1.

[0059] Step 3: Conditioning of sludge. Select appropriate conveying and mixing machinery and methods, add a certain proportion of condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com