Negative hydrogen ion water activating material and manufacturing method thereof

A technology of living water materials and negative hydrogen ions, applied in the field of materials, can solve the problems of difficult preparation and storage, negative hydrogen ions cannot exist alone, etc., and achieve the effects of high negative potential, good reduction effect, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

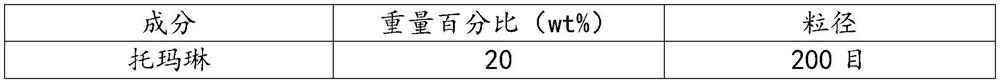

[0042] A kind of negative hydrogen ion living water material of the present embodiment, it is made up of tourmaline, ferric oxide, wood fish stone powder, iron powder, oyster shell powder, zeolite, clay, and its formula is as follows table 1:

[0043] Table 1

[0044] Element Weight percent (wt%) particle size tourmaline 20 200 mesh Iron oxide 10 200 mesh Muyu stone powder 10 500 mesh iron powder 10 500 mesh Oyster shell powder 20 900 mesh Zeolite 10 200 mesh Clay 20 200 mesh

[0045] The manufacture method of the negative hydrogen ion living water material of the present embodiment, comprises the steps:

[0046] a. Put the 7 kinds of materials into the container according to the above formula, stir evenly, add water, stir again, knead it into a cup shape with a thickness of 2mm, a diameter of 7cm, and a height of 10cm, and place it in a drying oven at a temperature of 50°C. : 24h for drying.

[0047] b...

Embodiment 2

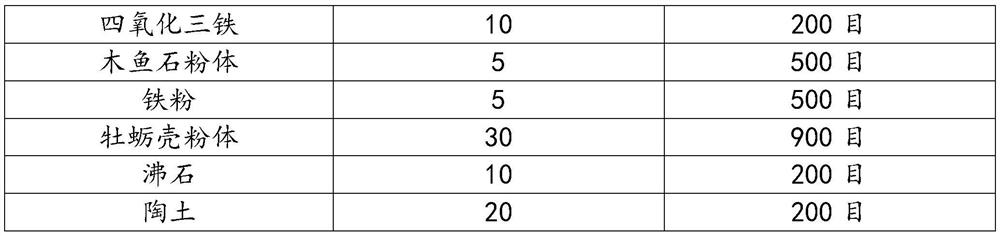

[0051] A kind of negative hydrogen ion living water material of the present embodiment, it is made up of tourmaline, ferric oxide, wood fish stone powder, iron powder, oyster shell powder, zeolite, pottery clay, and its formula is as follows table 2:

[0052] Table 2

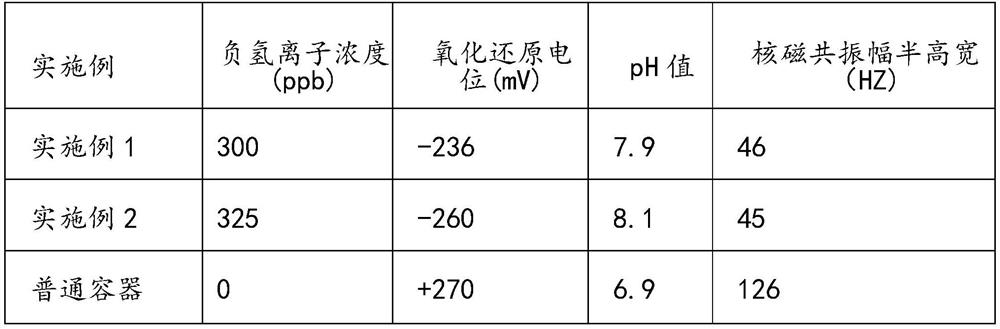

[0053]

[0054]

[0055] The manufacture method of the negative hydrogen ion living water material of the present embodiment, comprises the steps:

[0056] a. Put the 7 kinds of materials into the container according to the above formula, stir evenly, add water, stir again, knead it into a cup shape with a thickness of 2mm, a diameter of 7cm, and a height of 10cm, and place it in a drying oven at a temperature of 50°C. : 24h for drying.

[0057] b. Put the above-mentioned dried teacup-shaped container in a box-type high-temperature furnace, oxidize and sinter for 5 hours at a temperature of 600° C., and take it out after cooling.

[0058] c. Put the above-mentioned teacup-shaped container after oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com