High-hardness 316L stainless steel as well as preparation method and application thereof

A stainless steel, high-hardness technology, applied in the field of stainless steel, austenitic stainless steel, can solve problems such as unsatisfactory demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

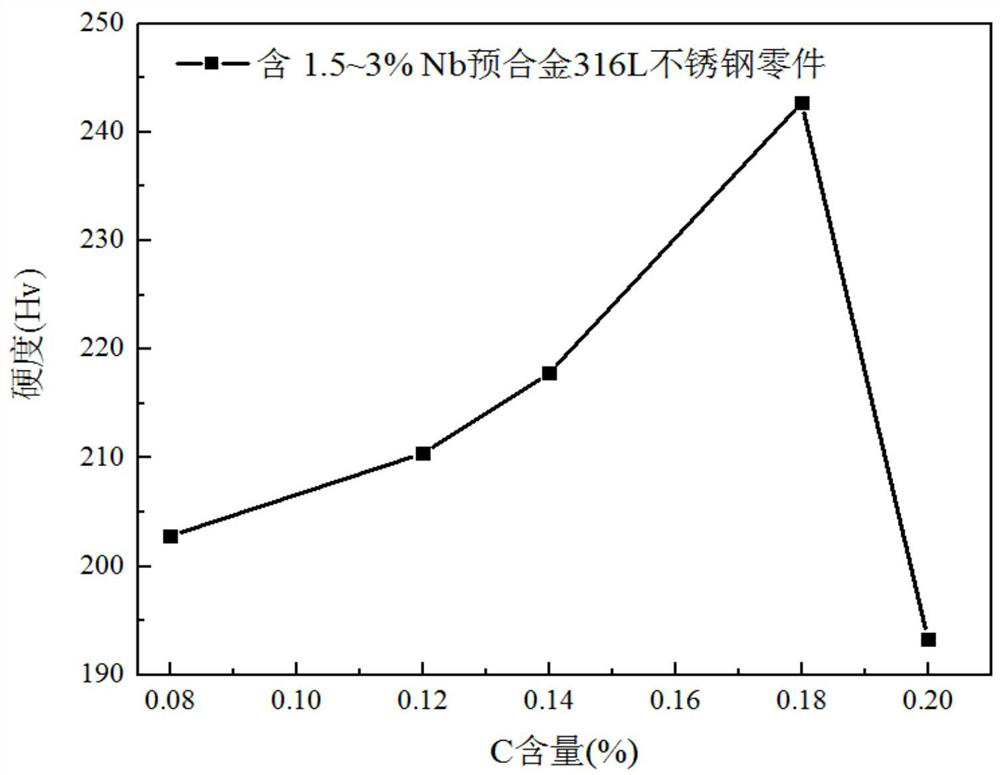

Embodiment 1

[0030] 316L stainless steel parts were made by injection molding. Specific process: 1.5% Nb pre-alloyed 316L stainless steel powder is prepared by mixing raw materials, which is composed of 17% Cr, 12% Ni, 2% Mo, 1.5% Nb, and the balance Fe. Mixed with 0.08% graphite powder. The powder is composed of graphite powder with an average particle size of 6-9 microns and Nb-containing pre-alloyed 316L stainless steel powder with an average particle size of 4-10 microns. Use paraffin wax and high-density polyethylene as the binder, mix the powder according to the volume ratio: binder = 6:4 (volume ratio); obtain the molded body through the injection molding process, and remove the organic binder through solvent degreasing and thermal degreasing . After the degreasing is completed, continue to raise the temperature for sintering in a nitrogen atmosphere (nitrogen partial pressure 80kPa), at a heating rate of 5°C / min, and keep the temperature at 1300°C for 2 hours. After the sample i...

Embodiment 2

[0032] 316L stainless steel parts were made by injection molding. Specific process: 2% Nb pre-alloyed 316L stainless steel powder is prepared by mixing raw materials, consisting of 17% Cr, 12% Ni, 2% Mo, 2% Nb, and the balance Fe. Mixed with 0.12% graphite powder. The powder is composed of graphite powder with an average particle size of 6-9 microns and Nb-containing pre-alloyed 316L stainless steel powder with an average particle size of 4-10 microns. Paraffin wax and high-density polyethylene are used as binders, according to the volume ratio, mixed powder: binder = 6:4 (volume ratio); mix the mixed powder and binder evenly to obtain feed, and inject the feed into the mold In the green body, the green body is obtained; the organic binder is removed by solvent degreasing and thermal degreasing. After the degreasing is completed, continue to raise the temperature to carry out sintering in a nitrogen atmosphere (nitrogen partial pressure 90kpa), the temperature rise rate is 5...

Embodiment 3

[0034] 316L stainless steel parts were made by injection molding. Specific process: 3% Nb pre-alloyed 316L stainless steel powder is prepared by mixing raw materials, consisting of 17% Cr, 12% Ni, 2% Mo, 3% Nb, and the balance Fe, mixed with 0.18% graphite powder. The powder is composed of graphite powder with an average particle size of 6-9 microns and Nb-containing pre-alloyed 316L stainless steel powder with an average particle size of 4-10 microns. Paraffin wax and high-density polyethylene are used as binders, according to the volume ratio, mixed powder: binder = 6:4 (volume ratio); mix the mixed powder and binder evenly to obtain feed, and inject the feed into the mold In the green body, the green body is obtained; the organic binder is removed by solvent degreasing and thermal degreasing. After the degreasing is completed, continue to raise the temperature and carry out sintering in a nitrogen atmosphere (nitrogen partial pressure 100kpa), at a heating rate of 5°C / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com