Post-treatment method of granular copper anode produced by pressing

A copper anode, granular technology, applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., to achieve the effect of good use effect, high drying efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

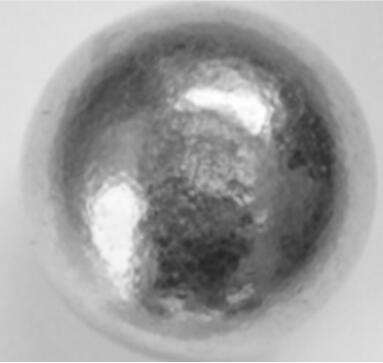

Image

Examples

Embodiment 1

[0026] This embodiment provides a post-treatment method for suppressing a particulate copper anode produced, comprising the steps of:

[0027] (1) Put the particulate copper anode into the vibrating polishing machine, add water to moisturize, then add the weight ratio of 1: 1 mixed alkyl sulfonate and sodium alkylbenzene sulfonate as a weak alkaline surfactant. The weight ratio of the particulate copper anode and the weakly alkali surfactant is 2400: 1. The vibration polishing machine is opened for 7 minutes, and the surface oil is removed, and the water is continuously flushed, rinsed into the oil-free non-foam, add 3-hydroxy-3- Carboxyxhaldic acid washing, the weight ratio of the particulate copper anode and 3-hydroxy-3-carboxylicenic acid is 2200: 1, and the vibration polishing is removed from the oxide, and finally the water is flushed to the copper anode surface light;

[0028] (2) Put the particulate copper in the step (1) into the vibrating centrifugal dewatering machine, t...

Embodiment 2

[0033] This embodiment provides a post-treatment method for suppressing a particulate copper anode produced, comprising the steps of:

[0034] (1) Put the particulate copper anode into the vibration polishing machine, add water to moisturize, then add a weak alkaline surfactant-alkylbenzene sulfonate, the weight ratio of the particulate copper anode and the weak baseive surfactant is 2500: 1, open the vibration polishing machine vibration polishing 8 minutes, remove the surface oil, continue to increase the water, rinse to the oil-free non-foam, add alkyl polysaccharide and 3-hydroxy-3-carboxylatonic acid mix (w: w = 1: 1) Weak acidic cleaning agent, weight ratio of particulate copper anode and weak acid cleaning agent is 2000: 1, vibration polishing 7min removal of oxidized skin, and finally continuously adding water to the copper anode surface light bright;

[0035] (2) Put the particulate copper in the step (1) into the vibrating centrifugal dewatering machine, then the particl...

Embodiment 3

[0040] This embodiment provides a post-treatment method for suppressing a particulate copper anode produced, comprising the steps of:

[0041] (1) Put the particulate copper anode into the vibration polishing machine, add water to moist and wet, then add a weak alkaline surfactant-alkyl sulfonate, the weight ratio of the particulate copper anode and sodium alkyl sulfonate is 2600: 1. Open the vibration polishing machine vibration and polishing 10 minutes, remove the surface oil, continue to increase the water, rinse to the oil-free non-foam, and add alkyl polysaccharide and 3-hydroxy-3-carboxylic acid (w: w = 1: 1) Mixed weak acidic cleaning agent, the weight ratio of the particulate copper anode and the weak acid cleaning agent is 2000: 1, and the vibration polishing is removed from the oxidized skin, and finally the water is flushing to the copper anode surface light;

[0042] (2) Put the particulate copper in the step (1) into the vibrating centrifugal dewatering machine, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com