Target layout correction method and mask layout forming method

A target correction and mask technology, applied in the field of correction method and mask layout formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

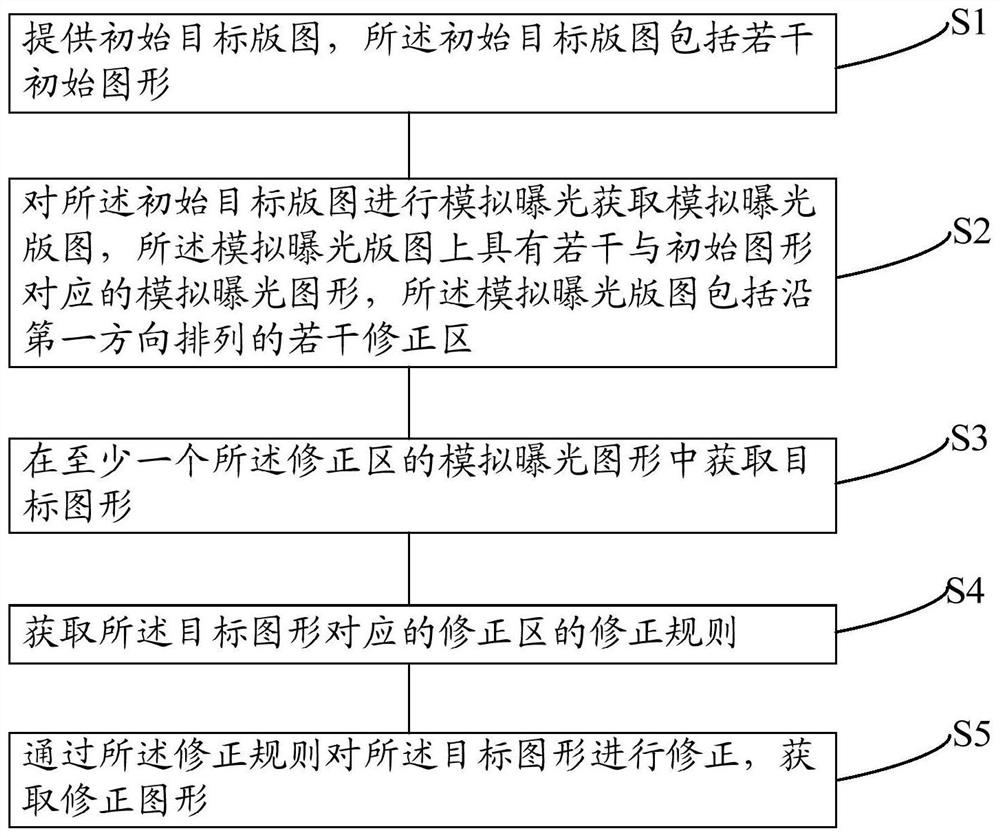

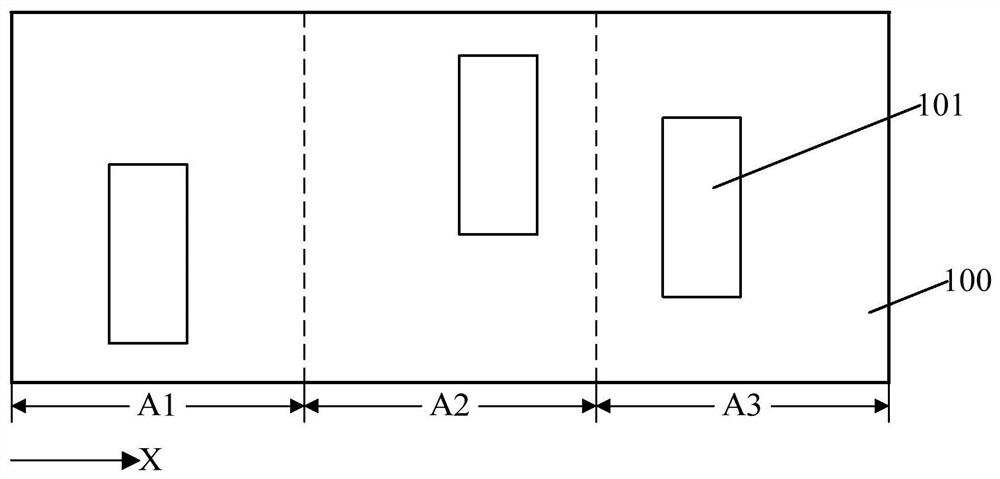

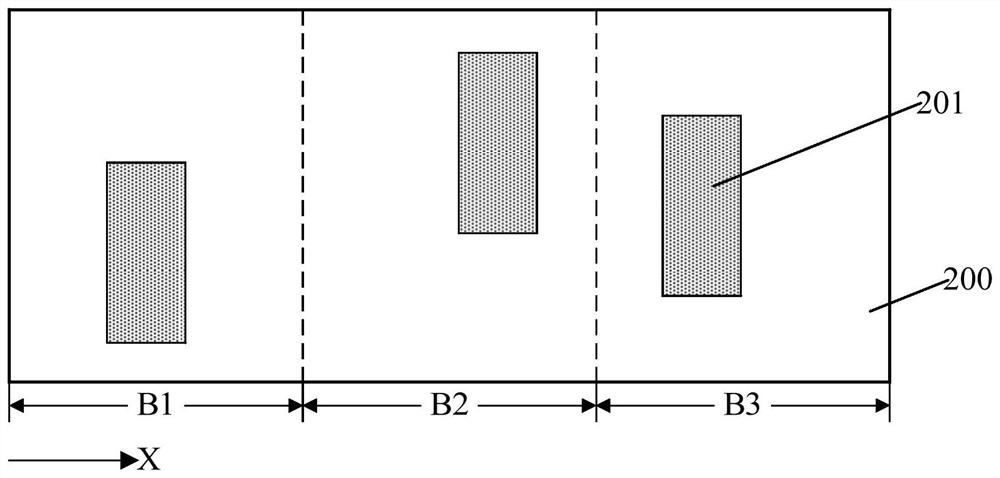

[0025] As mentioned in the background, there are still many problems in the mask plate formed by the existing extreme ultraviolet (EUV) exposure technology. Specifically, the extreme ultraviolet (EUV) exposure process is generally performed in a scanning manner. In an extreme ultraviolet (EUV) exposure system, scanning can be performed using slits that confine light to a local area of the mask, so that the mask The graphics on the plate are transferred to the substrate. The slit has a curved structure, and the curved structure enables the reflected light of extreme ultraviolet (EUV) to achieve uniform illumination distribution on the surface of the mask plate. And because the slit has a curved structure, the azimuth angles of the extreme ultraviolet light passing through different positions of the slit are different, so when the extreme ultraviolet light passes through the slit and irradiates the mask, it is reflected by the mask to the surface of the substrate Afterwards, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com