Roller mill production system suitable for tailing treatment

A production system and roller mill technology, applied in cement production, grain treatment, sustainable waste treatment, etc., can solve the problems of high energy consumption, low energy utilization rate, and scattering of ore powder in pneumatic conveying devices, and achieve the service life. The effect of long, small vibration and high-efficiency roller grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

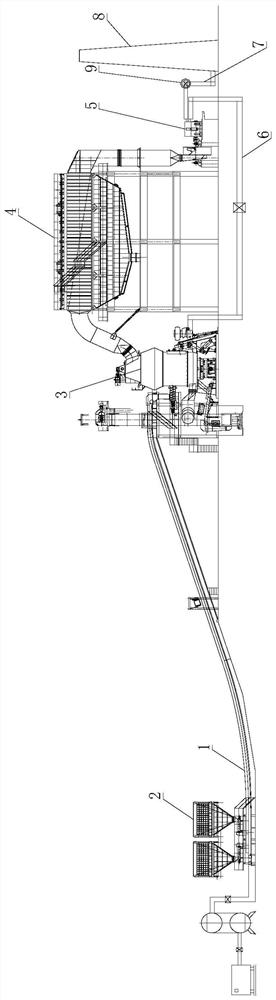

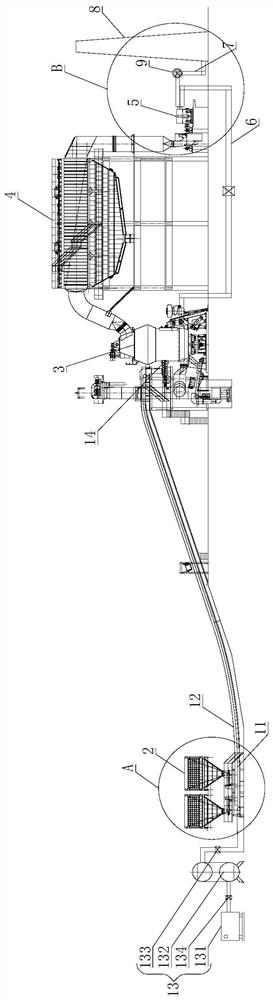

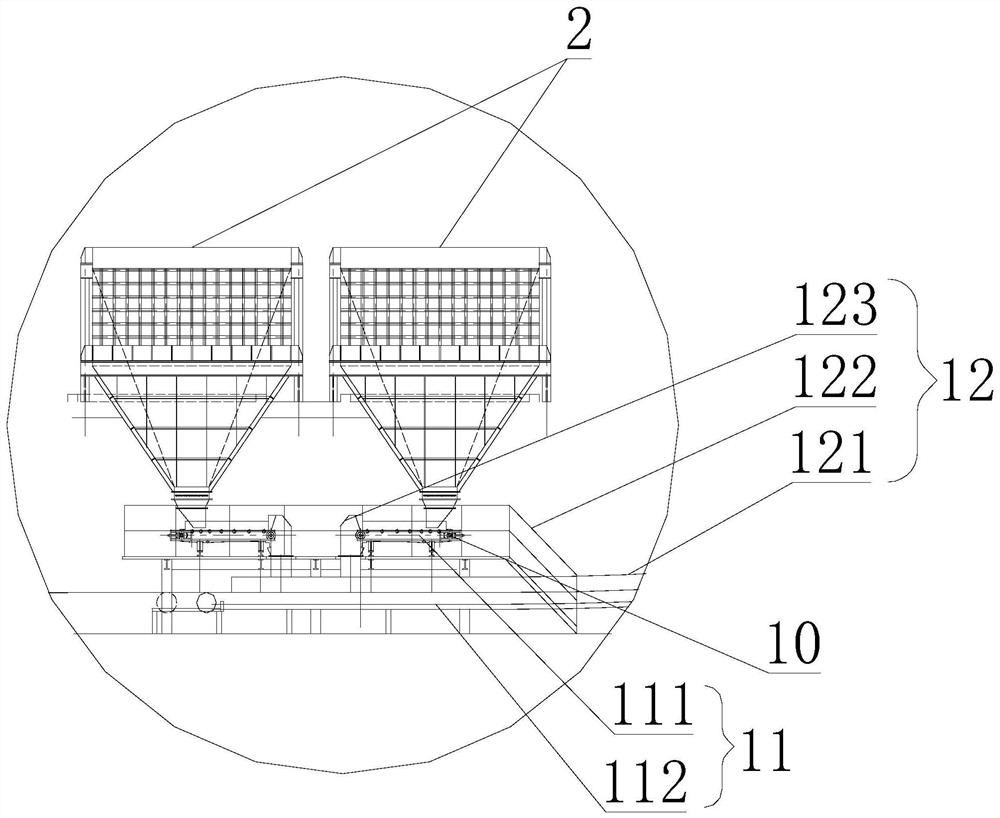

[0025] Such as Figure 1 to Figure 4 As shown, in order to enable the roller mill production system to perform efficient roller mill processing on tailings, the production process is stable and efficient, and energy-saving and environmentally friendly. Further, a roller mill production system suitable for tailings treatment provided in this embodiment , including pneumatic conveyor 1, raw material warehouse 2, vertical roller mill 3, air box pulse dust collector 4 and centrifugal fan 5, the discharge end of raw material warehouse 2 corresponds to the feed end of pneumatic conveyor 1, and the pneumatic The discharge end of the conveyor 1 corresponds to the feed end of the vertical roller mill 3, the discharge end of the vertical roller mill 3 corresponds to the feed end of the air box pulse dust coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com