Method for extracting high-purity scandium oxide from scandium-containing nickel-cobalt hydroxide through short process

A nickel-cobalt hydroxide and short-process technology, which is applied in the material field, can solve the problems of low scandium recovery rate, high production cost, and high cost, and achieve the effects of full extraction and purification, less equipment investment, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

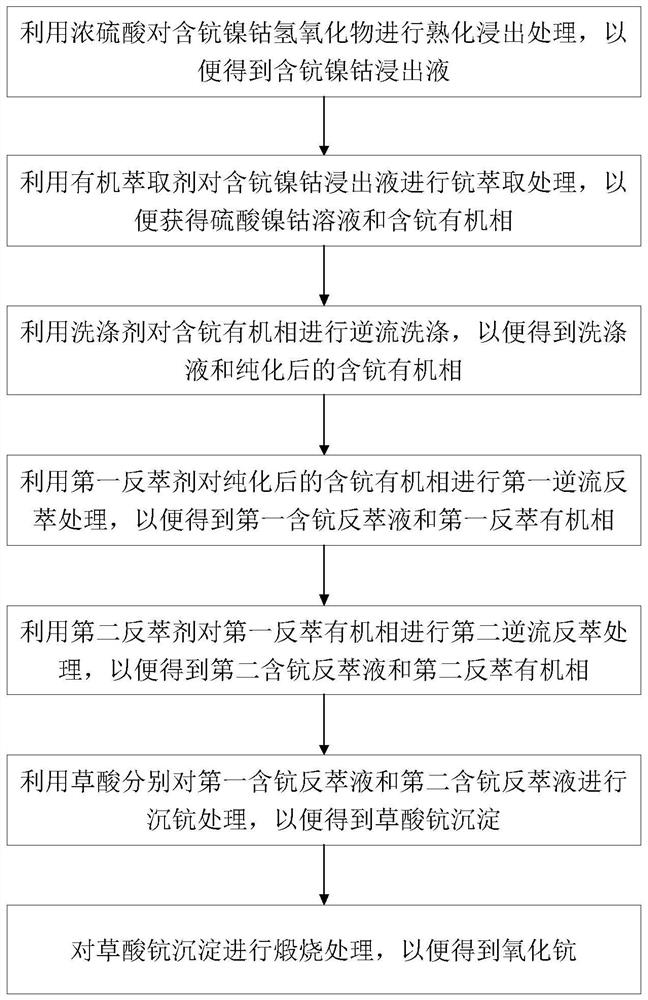

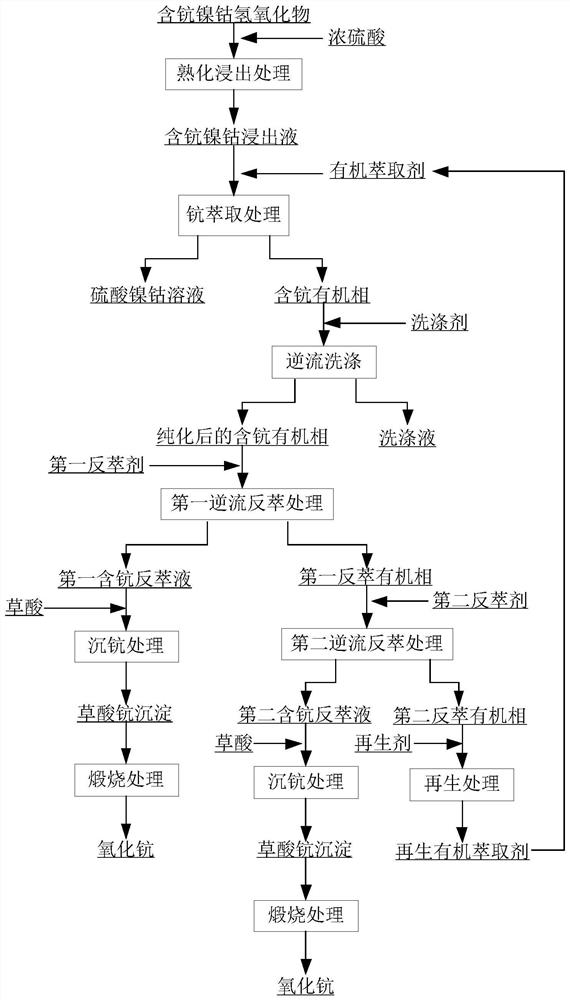

Method used

Image

Examples

Embodiment 1

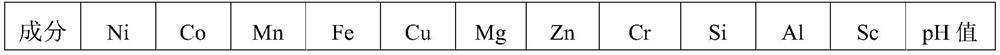

[0063] Table 1 shows the composition of the scandium-containing nickel-cobalt hydroxide raw material produced by the transformation of laterite nickel ore used in the following examples.

[0064] The composition (%) of nickel hydroxide cobalt raw material of table 1

[0065] Element Ni co mn Fe Cu Mg Zn Cr Si Al sc h 2 o

content 40.21 3.67 5.42 0.34 0.122 1.75 0.733 0.002 0.078 0.67 0.044 57

[0066] Take 100mL of nickel sulfate solution with a pH value of 1.0-2.0 as the bottom liquid, add 180mL of industrial concentrated sulfuric acid with a mass concentration of 93%, and then put it in a hot water bath at 80°C (for heat preservation, not for heating) and stir; add 1100g of scandium-containing nickel-cobalt hydroxide raw materials were aged and leached in a high-acid environment for a reaction time of 1.5 hours to obtain an aged leaching solution. The chemical composition of the scandium-nickel-cobalt solution after ag...

Embodiment 2

[0075] The difference from Example 1 is that the flow rate ratio of the organic extractant to the scandium-containing nickel-cobalt leaching solution in the mixing and clarifying extraction tank is 1:15. The extraction rate of each element is shown in Table 4.

[0076] Table 4 Example 2 The extraction rate (%) of each element in scandium-containing organic phase

[0077] element Ni co mn Fe Cu Mg Zn Cr Si Al sc Extraction rate 1.5 0.25 0.3 7 0.2 0.11 0.26 0.22 1.3 0.35 >99.9

Embodiment 3

[0079] The difference from Example 1 is that the flow rate ratio of the organic extractant to the scandium-containing nickel-cobalt leaching solution in the mixing and clarifying extraction tank is 1:25. The extraction rate of each element is shown in Table 4.

[0080] Table 5 Example 3 The extraction rate (%) of each element in scandium-containing organic phase

[0081] element Ni co mn Fe Cu Mg Zn Cr Si Al sc Extraction rate 0.8 0.14 0.21 3.7 0.11 0.1 0.15 0.19 0.85 0.26 99.6

[0082] Comparing Examples 1 to 3, it can be seen that under the same conditions, when the ratio of the flow rate of the organic extractant to the scandium-containing nickel-cobalt leaching solution in the mixing and clarifying extraction tank is 1:15, the extraction rate of scandium is higher, not less than 99%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com