A kind of preparation method of dyeable graphene-nylon composite material

A nylon composite material and composite material technology are applied in the field of graphene-nylon composite material preparation, which can solve the problem that polyamide composite materials cannot be dyed, and achieve the effects of being conducive to industrial application, simple process flow, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using dimethyl sulfoxide (DMSO) as solvent, the graphene-nylon composite material was prepared by the polymerization reaction of 20% by mass of sulfonated graphene, 78% of nylon 6 and 2% of triazine DSD acid additives. The reaction steps are as follows:

[0025] (1) Sulfonated graphene (sulfur content is 0.5%) is added to dimethyl sulfoxide (DMSO) solvent, and ultrasonically oscillated for 0.5 h to obtain sulfonated graphene-dimethyl sulfoxide with a mass concentration of 20 mg / mL, which is uniformly dispersed liquid;

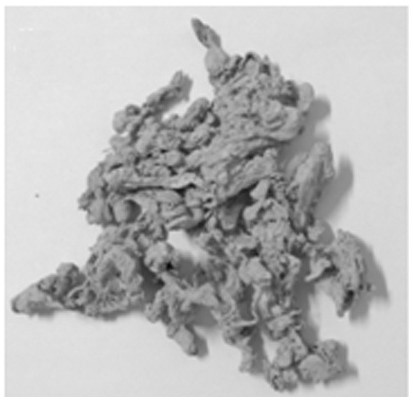

[0026] (2) Adding the uniform dispersion obtained in step (1), triazine DSD acid additives, nylon 6 and solvent DMSO to the reaction kettle, and reacting at 160 ° C for 4 hours to obtain graphene-nylon 6 composite material; figure 1 Shown is the schematic diagram of the graphene-nylon 6 composite material of the present invention, that is, the schematic diagram of the graphene-nylon 6 composite material before dyeing;

[0027] (3) adding methylene blue...

Embodiment 2

[0030] Using dimethyl sulfoxide (DMSO) as solvent, the graphene-nylon composite material was prepared by the polymerization reaction of 25% of sulfonated graphene, 72% of nylon 66 and 3% of triazine DSD acid additives. The reaction steps are as follows:

[0031] (1) Sulfonated graphene (sulfur content is 10%) is added to dimethyl sulfoxide (DMSO) solvent, and ultrasonically oscillated for 0.5 h to obtain sulfonated graphene-dimethyl sulfoxide with a mass concentration of 50 mg / mL, which is uniformly dispersed liquid;

[0032] (2) Adding the uniform dispersion obtained in step (1), triazine DSD acid additives, nylon 66 and solvent DMSO to the reaction kettle, and reacting at 160 ° C for 4 hours to obtain graphene-nylon 66 composite material;

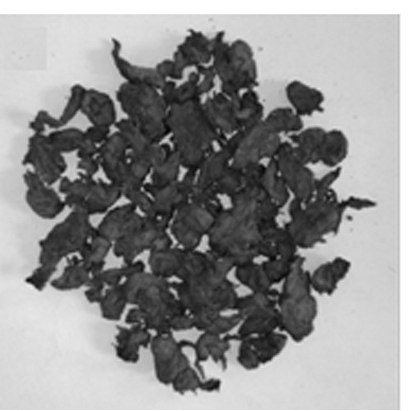

[0033] (3) Adding Rhodamine B to the prepared off-white graphene-nylon composite material to make a pink graphene-nylon composite material; image 3 Schematic diagram of the graphene-nylon 66 composite material after adding Rhodamine B ...

Embodiment 3

[0035] Using dimethyl sulfoxide (DMSO) as solvent, the graphene-nylon composite material was prepared by the polymerization reaction of 35% of sulfonated graphene, 60% of nylon 610 and 5% of stilbene biphenyl additives. The reaction steps are as follows:

[0036] (1) Sulfonated graphene (sulfur content is 30%) is added to dimethyl sulfoxide (DMSO) solvent, and ultrasonically oscillated for 0.5 h to obtain sulfonated graphene-dimethyl sulfoxide with a mass concentration of 80 mg / mL, which is uniformly dispersed liquid;

[0037] (2) Adding the uniform dispersion obtained in step (1), triazine DSD acid additives, nylon 610 and solvent DMSO to the reaction kettle, and reacting at 160 ° C for 4 hours to obtain graphene-nylon 610 composite material;

[0038] (3) Adding Rhodamine B to the prepared off-white graphene-nylon 610 composite material to make pink graphene-nylon composite material;

[0039] (4) The graphene-nylon 610 composite material was made into a standard spline with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com