Composite material, preparation method thereof and light-emitting diode

A technology of composite materials and luminescent materials, which is applied in the field of display materials and can solve problems such as low energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] On the one hand, the embodiment of the present invention provides a kind of preparation method of composite material, such as figure 1 Shown, this preparation method comprises the steps:

[0025] S01: adding the host organic light-emitting material into the solution containing the guest quantum dot material, and performing heat treatment to obtain the composite material;

[0026] Wherein, the host organic luminescent material is connected with a chemical functional group, and the chemical functional group is a binding group combined with the guest quantum dot material.

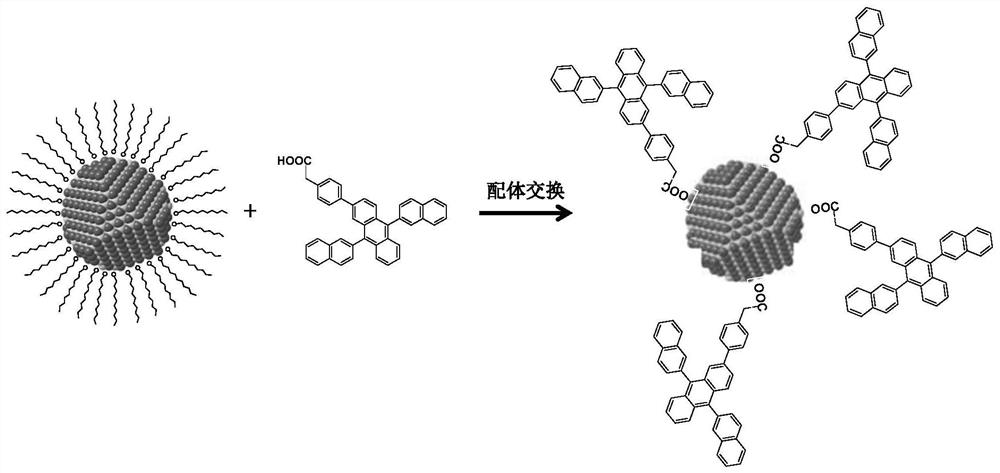

[0027] In the prior art, the host luminescent material and guest quantum dots are used as the luminescent layer. The host and guest are directly mixed. Since the surface of the quantum dots is generally attached with a layer of insulating organic ligands (ie, the initial ligands), this layer of ligands The physical length is about 0.5-1nm, which greatly exceeds the contact distance between the host and...

Embodiment 1

[0059] A kind of preparation method of composite material:

[0060] The guest quantum dots are CdZnSe / ZnSe / ZnS, and the host for ligand exchange is carboxylated anthracenyl molecules (named host A) As an example; specific steps include:

[0061] Add 20ml of host A material (concentration: 10mg / ml) to 50.0ml (concentration: 5mg / ml) of n-octane solution of CdZnSe / ZnSe / ZnS quantum dots. The mixture was stirred at room temperature for 20 minutes to 2 hours. Add 25-100ml of precipitant (ethanol) to the reaction solution to precipitate the composite material from the solution, and then separate the precipitated composite material to the bottom of the solution by spinning at 5000-7000 rpm, pour the supernatant and then add benign Solvent (n-octane). The washing step was repeated 2-3 times for better purification of the composite.

Embodiment 2

[0063] A kind of preparation method of composite material:

[0064] The guest quantum dots are CdZnSe / ZnSe / ZnS, and the host for ligand exchange is an aminated TADF material molecule (named host B) As an example; specific steps include:

[0065] Add 20ml of host B material (concentration: 10mg / ml) to 50.0ml (concentration: 5mg / ml) of n-octane solution of CdZnSe / ZnSe / ZnS quantum dots. The mixture was stirred at room temperature for 20 minutes to 2 hours. 25-100ml of precipitating agent (ethanol) is added to the reaction solution, the composite material is precipitated from the solution, and then the precipitated composite material is separated to the bottom of the solution by spinning at 5000-7000 rpm. After pouring the supernatant, add a benign solvent (n-octane). The washing step was repeated 2-3 times for better purification of the composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com