Special oil for maintenance of telescopic boom of crane and preparation method thereof

A technology for telescopic arms and cranes, which is applied in the field of special oil for crane telescopic arm maintenance and its preparation, which can solve the problems of reduced lubricating effect of telescopic arms, affecting work efficiency, short effective time, etc., achieves good shape retention effect, and prolongs the maintenance cycle , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

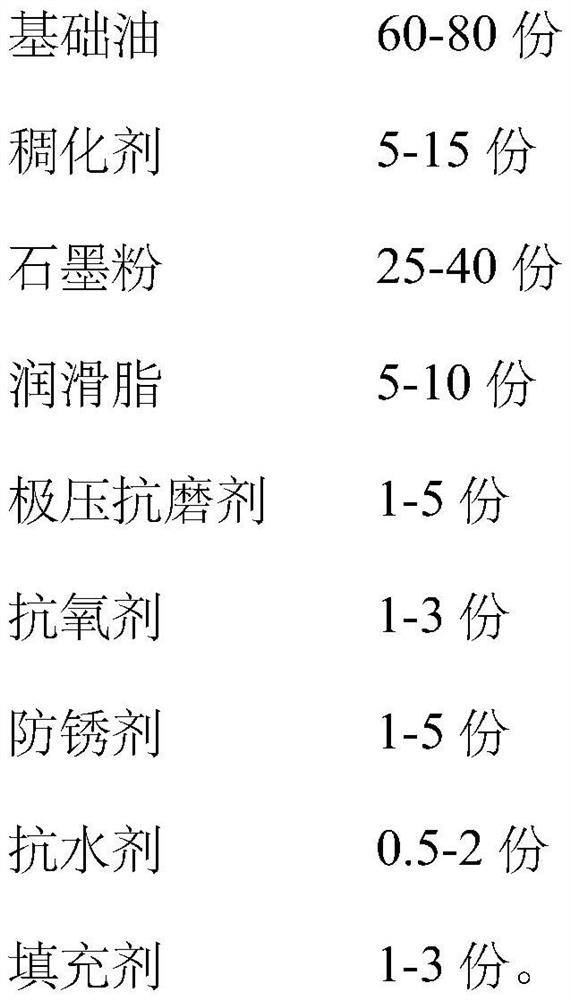

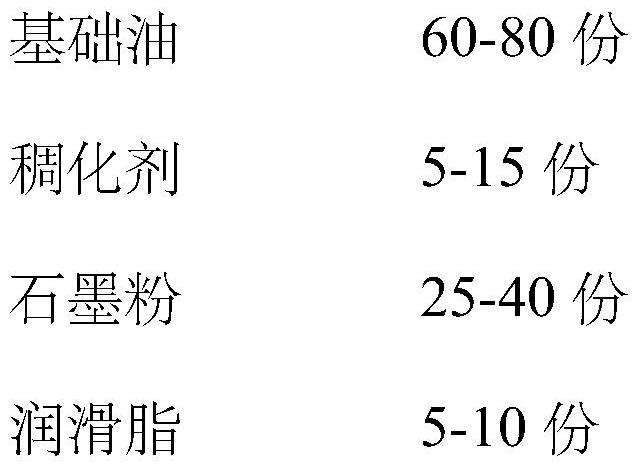

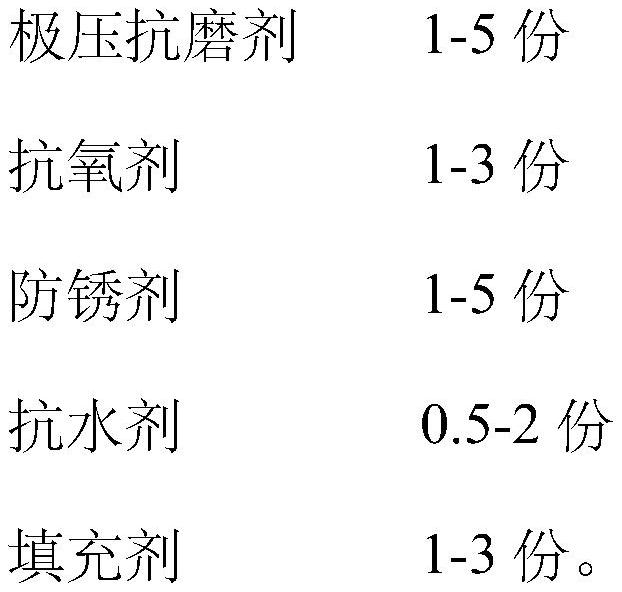

Method used

Image

Examples

Embodiment 1

[0025] A crane telescopic arm maintenance special oil, characterized in that the number of components, 38 parts of polyether, 34 parts of polyether, 10 parts of polyuretin, 32 graphite powder, 32 graphite powder, polyuretin 5 parts of methacrylate, 3 parts of extreme pressure anti-wear, 2 antioxidants, 4 rust inhibitor, 1 zirconium carbonate, 2 parts of molybdenum sulfide.

[0026] The preparation method includes the following steps, accurately weigh the components; mix the polyether to the poly alpha-olefin to form the base oil, and the partial oil is added to the reaction kettle, then the polyurea thickener and polymethyl group are added. Methyl acrylate, heating and stirring, reacting 1-2 h, resulting in initiation; adding the remaining base oil to the initiator, and graphite powder, extreme pressure anti-wear agent (borate ammonium salt and dibenzyl) Sulfide 1: 1 compound), antioxidant, rust inhibitor, zirconium carbonate and molybdenum disulfide, stir well, and reactively obt...

Embodiment 2

[0028] A crane telescopic arm maintenance dedicated oil, characterized in that the number of components, 32 parts of polyether, 33 parts of polyether, 33 polyuretins, 38 graphite powder, 38 graphite powder, 38 graphite powder, 38 graphite powder, 38 graphite powder 10 parts of acrylic, 2 electrode anti-wear agents, 2 antioxidants, 2 rust reactants, 2 zirconium carbonate, 1 bosside molybdenum sulfide.

[0029] The preparation method includes the following steps, accurately weigh the components; mix the polyether to the poly alpha-olefin to form the base oil, and the partial oil is added to the reaction kettle, then the polyurea thickener and polymethyl group are added. Acrylic acid, heating and stirring, reacting 1-2 h, preparing initiation; adding the remaining base oil to the initiator, as well as graphite powder, extreme pressure anti-wear agent (borate ammonium salt and dibenzyl disulfide 1: 1 compound), antioxidant, rust inhibitor, zirconium carbonate and molybdenum disulfide,...

Embodiment 3

[0031] A crane telescopic arm maintenance special oil, characterized in that the number of components, 38 parts of polyether, 40 parts of polyether, 5 copies, 36 parts of calcium-modified bentonite, 36 copies, polymethyl 8 parts of methacrylate, 5 parts of extreme pressure anti-wear, 3 oxygen oxygen, 3 servust, 2 parts of zirconium carbonate, and 1 diomide.

[0032] The preparation method includes the following steps, accurately weigh the components; mix the polyether to the polyalpha-olefin to form the base oil, add some base oil to the reaction kettle, then add calcium-modified bentonite and polymethyl. Methyl acrylate, heating and stirring, reacting 1-2 h, resulting in initiation; adding the remaining base oil to the initiator, and graphite powder, extreme pressure anti-wear agent (borate ammonium salt and dibenzyl) Sulfide 1: 1 compound), antioxidant, rust inhibitor, zirconium carbonate and molybdenum disulfide, stir well, and reactively obtain crane telescopic arm maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com