Sea intestine gum as well as preparation method and application thereof

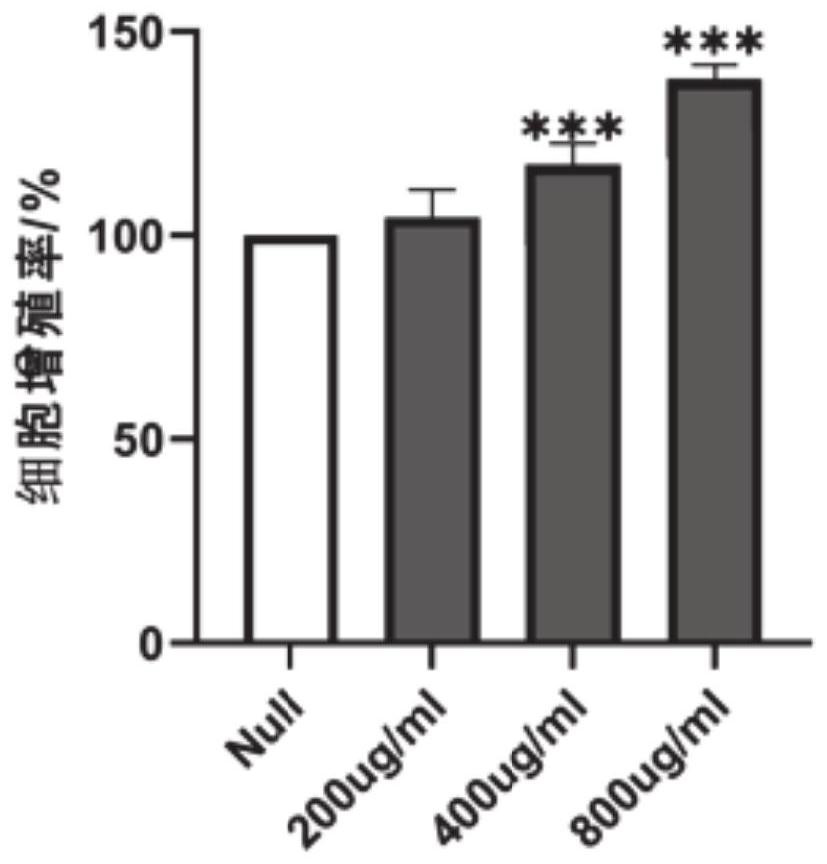

A sea intestine and buffer technology, applied in the field of sea intestine glue and its preparation, can solve the problems of unfavorable large-scale popularization or use, inability to use drugs or experimental reagents, single components and functions, etc., to promote macrophage proliferation, The effect of widening the utilization route and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In a first aspect, the present invention provides a method for preparing sea intestine gum, comprising the following steps:

[0025] The enzymolysis solution is obtained by mixing sea intestine, buffer solution and protease, heating at high temperature and drying.

[0026] The purpose of enzymatic hydrolysis of sea intestine is to increase the yield of sea intestine glue, the purpose of high temperature heating is to remove fishy smell, and the purpose of drying is to form glue, heat and dry sea intestine glue in an oven, and cut the dried glue into long strips Continue to dry, turn the rubber block regularly during the period, keep the same wind and low humidity, prevent the rubber block from getting wet, until it is completely dry and solid, that is, the finished sea intestine glue is obtained.

[0027] In order to improve the quality and purity of the sea intestine glue from the source, the sea intestine also includes a pretreatment step before mixing with the buffer...

Embodiment 1

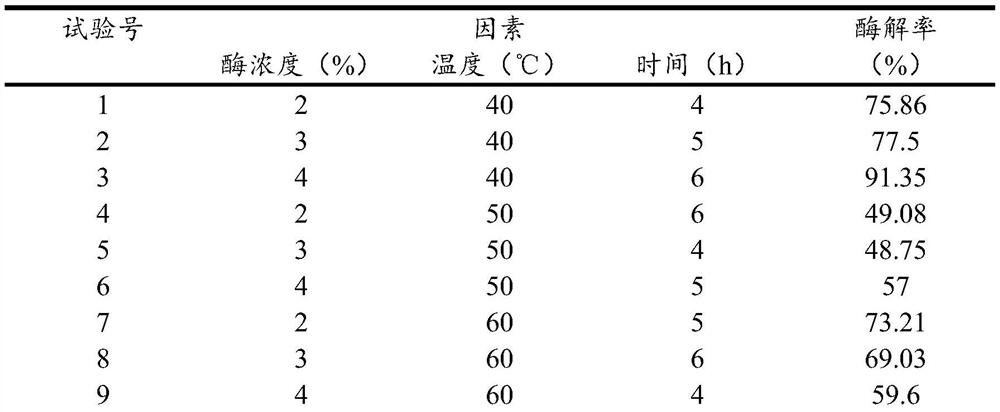

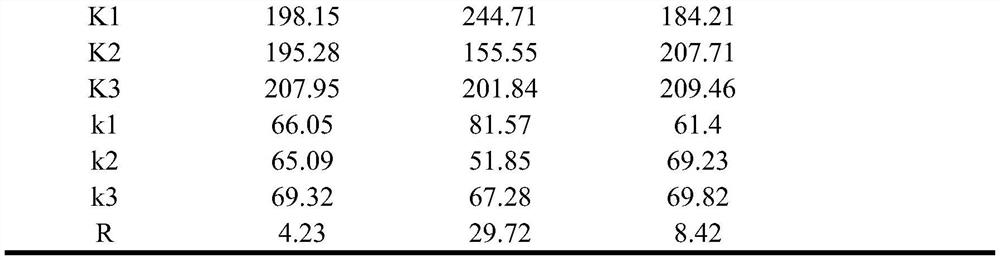

[0053] Example 1: Research on enzymatic hydrolysis conditions of sea intestine glue:

[0054] (1) Selection of hydrolase: The study was divided into three groups, using neutral protease, papain and bromelain respectively.

[0055] (2) Sea sausage pretreatment: Take 2 kg of fresh sea sausage, wash it with tap water, remove the viscera, etc., and leave the body wall muscle for later use. Then tap water and distilled water were washed repeatedly until no foam was produced, and the water in the sea intestine was dried and weighed.

[0056] (3) Enzymolysis: The research is divided into using a homogenizer to homogenate, adding phosphate buffer (pH 7.0) of 1 times the mass of sea intestine, and then adding 3% neutral protease, papain, bromelain, respectively, After stirring evenly, add the sea sausage, place in a water bath at a constant temperature of 50°C for 4 hours, and stir continuously during the whole process to obtain the enzymatic hydrolysis solution. Subsequently, the te...

Embodiment 2

[0063] (1) Sea sausage pretreatment: Take 2 kg of fresh sea sausage, wash it with tap water, remove the viscera, etc., and leave the body wall muscle for later use. Then use tap water and distilled water to elutriate repeatedly until no foam is produced, control the moisture in the sea intestine and then weigh it.

[0064] (2) Enzymolysis: Use a homogenizer to homogenate, add phosphate buffer (pH 7.0) that is 1 times the weight of sea intestine, then add 3% bromelain, stir well, add sea intestine, and place in a constant temperature water bath at 40°C 5h, stirring continuously during the whole process, to obtain the enzymatic hydrolysis solution. Subsequently, the temperature of the water bath was adjusted to 80° C. for 4 minutes to inactivate the enzyme and stop the reaction. Then, the enzymolysis solution was rapidly cooled to below 30°C and left for 30 minutes.

[0065] (3) Deodorization: Centrifuge the sea intestine hydrolyzate at room temperature (1000rpm, 20min), keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com