Dyed fabric capable of being subjected to high-temperature chlorine bleaching

A chlorine bleaching and fabric technology is applied in the field of high-temperature chlorine bleaching dyed fabrics, which can solve problems such as poor resistance to high-temperature chlorine bleaching, achieve good high temperature resistance and chlorine bleaching resistance, and increase adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

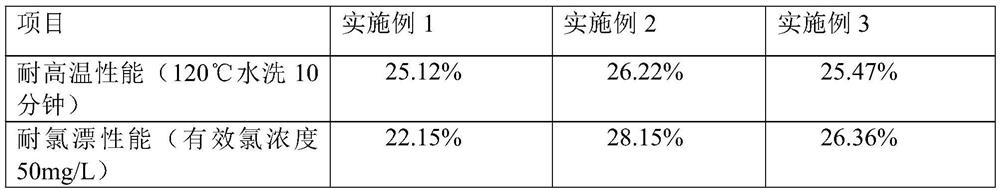

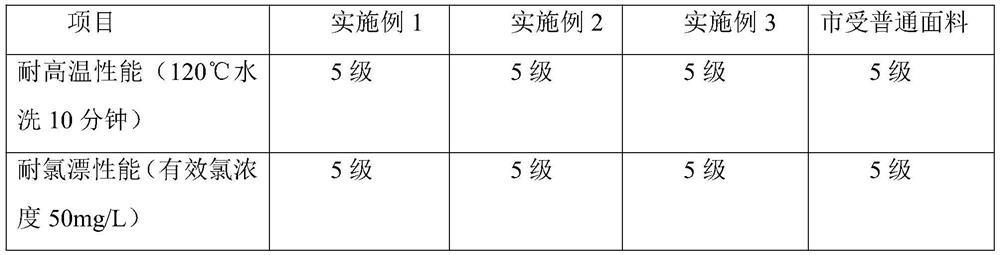

Examples

Embodiment 1

[0014] A dyed fabric capable of high-temperature chlorine bleaching, comprising the following components in parts by weight: 30 parts of coated nano-silver powder solution, 10 parts of tetraacetylethylenediamine, 10 parts of dihydropyridine, ethylenediamine di-o-hydroxybenzene 6 parts of sodium ferric acetate, 6 parts of ethylene-vinyl acetate copolymer, 20 parts of high temperature resistant stabilizer, 40 parts of polyvinylpyrrolidone, 40 parts of polyoxyethylene phenylalkylphenol ether and 40 parts of fatty alcohol polyoxyethylene ether.

[0015] The high temperature resistant stabilizer comprises: 70 parts by weight of tris(2,3-dichloropropyl) phosphate, 10 parts by weight of 5-ethylidene-2-norbornene, poly Vinyl acetate emulsion is 2 parts.

Embodiment 2

[0017] A dyed fabric capable of high-temperature chlorine bleaching, comprising the following components in parts by weight: 50 parts of coated nano-silver powder solution, 20 parts of tetraacetylethylenediamine, 16 parts of dihydropyridine, ethylenediamine di-o-hydroxybenzene 14 parts of sodium ferric acetate, 8 parts of ethylene-vinyl acetate copolymer, 30 parts of high temperature resistant stabilizer, 60 parts of polyvinylpyrrolidone, 80 parts of polyoxyethylene phenylalkylphenol ether and 60 parts of fatty alcohol polyoxyethylene ether.

[0018] The high temperature resistant stabilizer comprises: 85 parts by weight of tris(2,3-dichloropropyl) phosphate, 20 parts by weight of 5-ethylidene-2-norbornene, poly Vinyl acetate emulsion is 3.5 parts.

Embodiment 3

[0020] A dyed fabric capable of high-temperature chlorine bleaching, comprising the following components in parts by weight: 40 parts of coated nano-silver powder solution, 15 parts of tetraacetylethylenediamine, 13 parts of dihydropyridine, ethylenediamine di-o-hydroxybenzene 10 parts of sodium ferric acetate, 7 parts of ethylene-vinyl acetate copolymer, 25 parts of high temperature resistant stabilizer, 50 parts of polyvinylpyrrolidone, 65 parts of polyoxyethylene phenylalkylphenol ether and 50 parts of fatty alcohol polyoxyethylene ether.

[0021] Described high temperature resistant stabilizer comprises: the parts by weight of tris(2,3-dichloropropyl) phosphate is 78 parts by weight, the parts by weight of 5-ethylidene-2-norbornene is 15 parts by weight, poly Vinyl acetate emulsion is 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com