Post-insertion unbonded steel strand U-shaped pipe pressure-bearing type uplift pile and construction method thereof

A steel strand, non-adhesive technology, applied in foundation structure engineering, sheet pile walls, protective devices, etc., can solve the problems of difficult guarantee of grouting body strength, insufficient protective layer, low bearing capacity, etc., to achieve convenient processing, Excellent strength and quality, high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

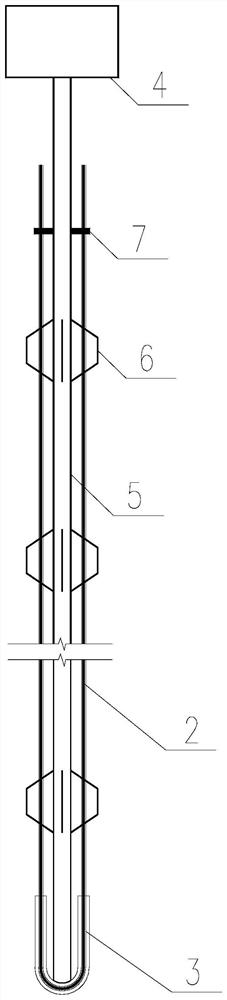

[0047] The following is attached Figure 1-9 The application is described in further detail.

[0048] The embodiment of the present application discloses a back-inserted unbonded steel strand U-shaped tube pressure-bearing uplift pile.

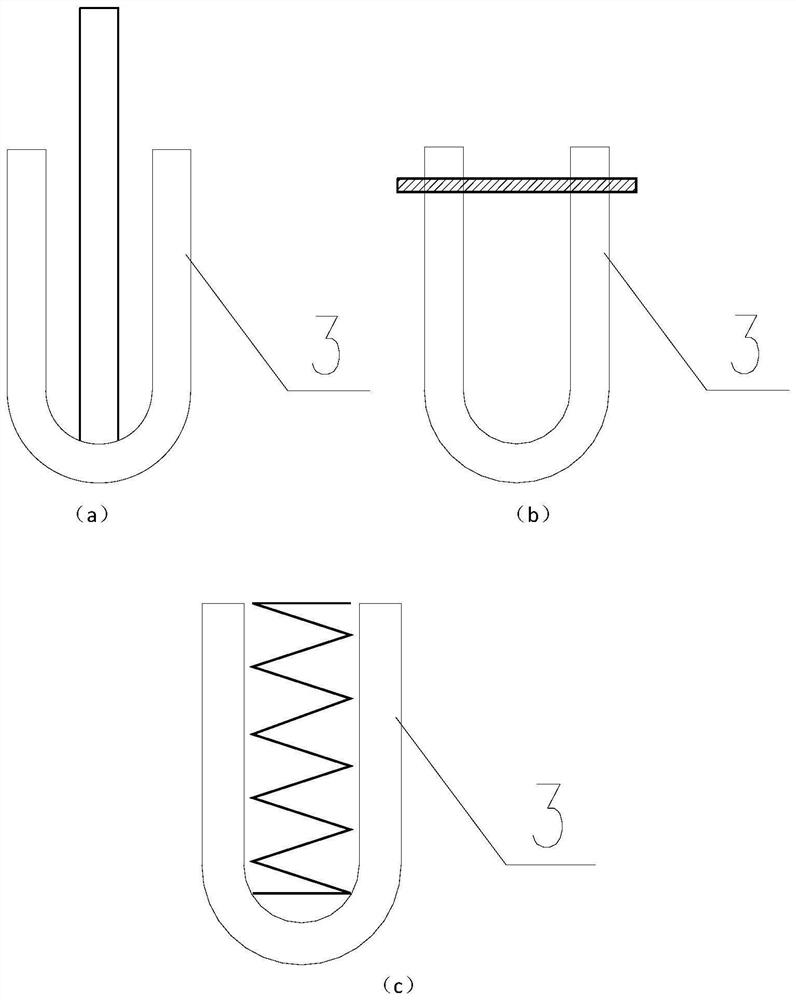

[0049] refer to Figure 1-Figure 9 , including the following components: Concrete pile body 1, unbonded steel strand 2, U-shaped tube pressure member 3, vibration or pressure device 4, hammer tube 5, positioning guide device 6, positioning fixture 7, foundation 8 , anchor plates and anchors 9, steel stirrups 10, waterproof cushion 11, extruded anchors, embossed anchors or anchors 12.

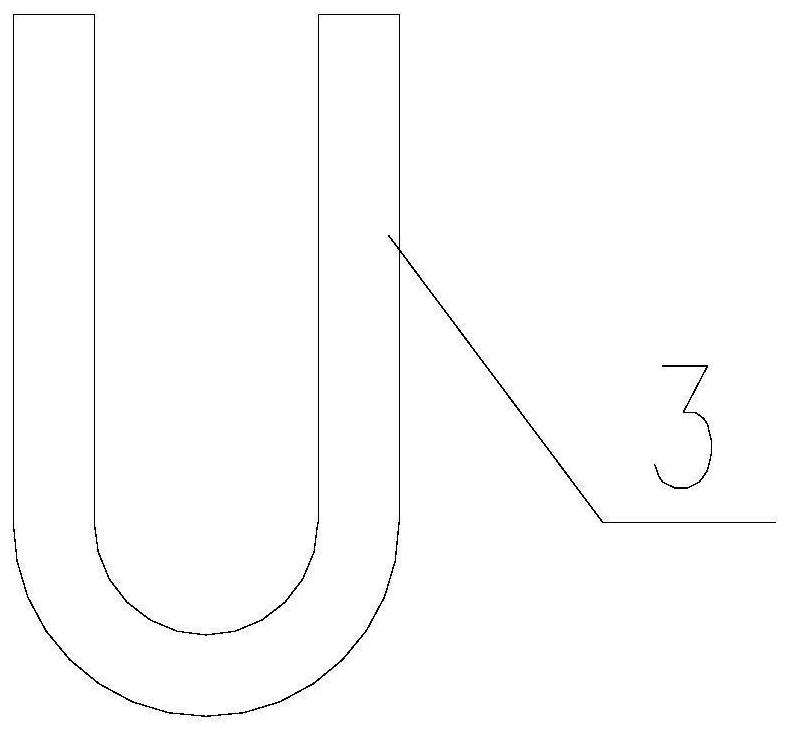

[0050] refer to figure 1 and figure 2 , The U-shaped tube in U-shaped tube pressure member 3 is made of steel pipe, galvanized pipe, welded pipe, aluminum tube, polymer material, etc., with a wall thickness of 2.5-20mm and an outer diameter of 25-100mm; the total length of the U-shaped tube and the U The vertical standpipe spacing of the type pipe is deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com