Control method of combustion system, combustion system and internal combustion engine

A combustion system and control method technology, applied in fuel injection control, electrical control, engine control, etc., can solve the problems of low air utilization, high fuel consumption of internal combustion engines, and low thermal efficiency, so as to promote rapid combustion, improve combustion efficiency, and improve The effect of burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides an internal combustion engine. The internal combustion engine includes a combustion system. The combustion system mixes fuel and air and burns in a cylinder. The released heat can generate high-temperature and high-pressure gas in the cylinder. The gas expansion pushes the piston to do work, and then the mechanical work is output through the crank connecting rod mechanism or other mechanisms to drive the driven machinery to work.

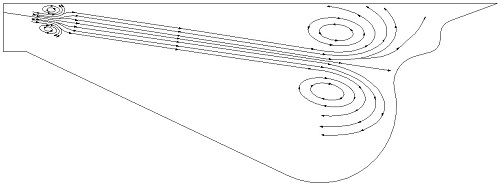

[0036] The combustion system adopted by the internal combustion engine provided in this embodiment avoids excessive concentration of fuel at one time, and utilizes the spatial superposition of the entrainment effect generated between the first-stage main fuel injection and the second-stage main fuel injection, thereby improving the combustion efficiency and reducing the The fuel consumption is improved and the economy of the internal combustion engine is improved.

[0037] This embodiment also provides a combustion sy...

Embodiment 2

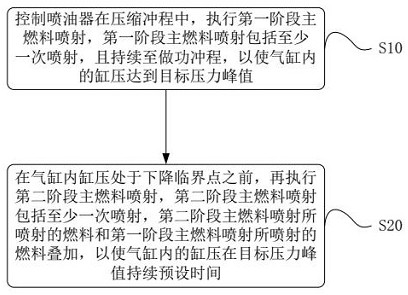

[0044] like figure 1 As shown, this embodiment provides a control method for a combustion system, and the control method for the combustion system includes:

[0045] S10. Control the injector to perform a first-stage main fuel injection during the compression stroke. The first-stage main fuel injection includes at least one injection and lasts until the power stroke, so that the cylinder pressure in the cylinder reaches the target pressure peak.

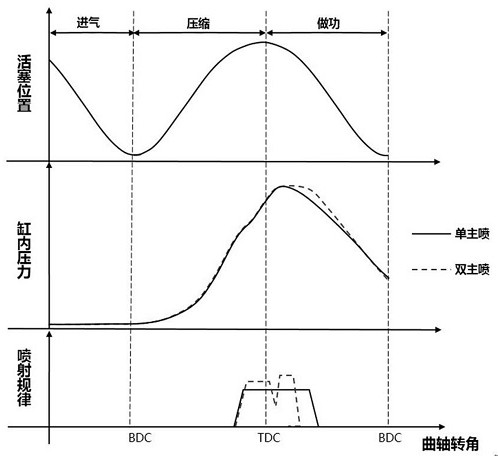

[0046] As a preferred embodiment of the control method of the combustion system, such as figure 2 As shown, the first stage main fuel injection includes a single injection that lasts from the piston compression stroke to the piston power stroke to establish a target pressure peak in the cylinder. It should be noted that in figure 2 Among them, single main injection refers to a single main fuel injection, dual main injection refers to the first stage main fuel injection and the second stage main fuel injection, TDC refers to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com