In2O3/alpha-Fe2O3 nanowire, triethylamine sensor and preparation method of In2O3/alpha-Fe2O3 nanowire

A sensor and nanowire technology, applied in nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve problems such as limitations and low sensitivity, and achieve improved sensitivity and response speed, small size, and simple device technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

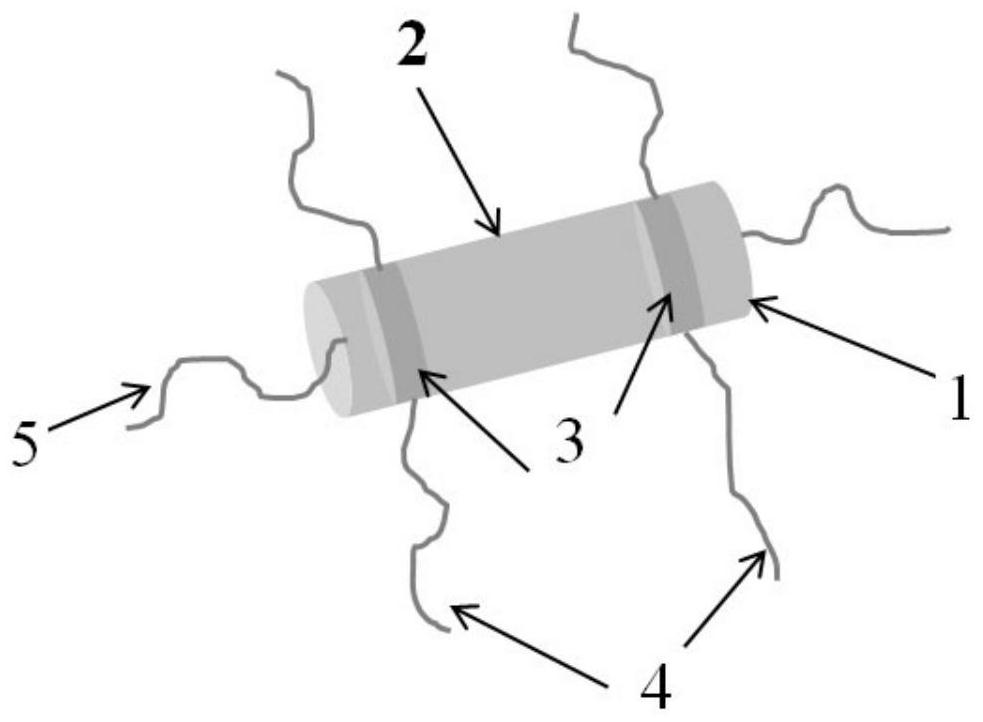

[0034] Based on 2 o 3 / α-Fe 2 o 3 A triethylamine sensor of nanowires and a preparation method thereof, comprising the following steps,

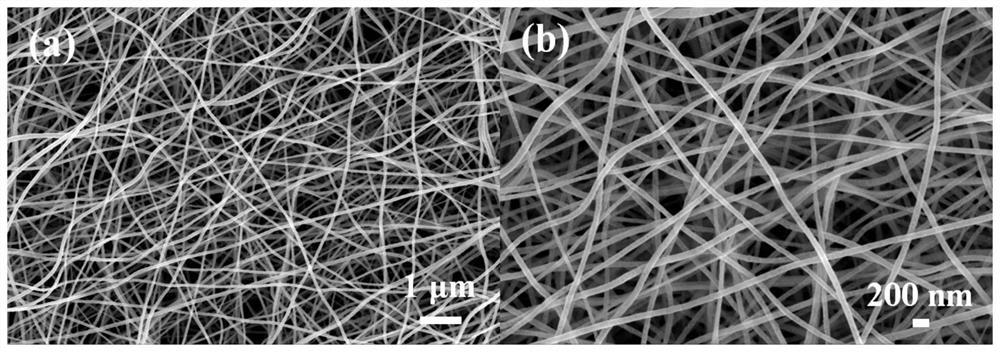

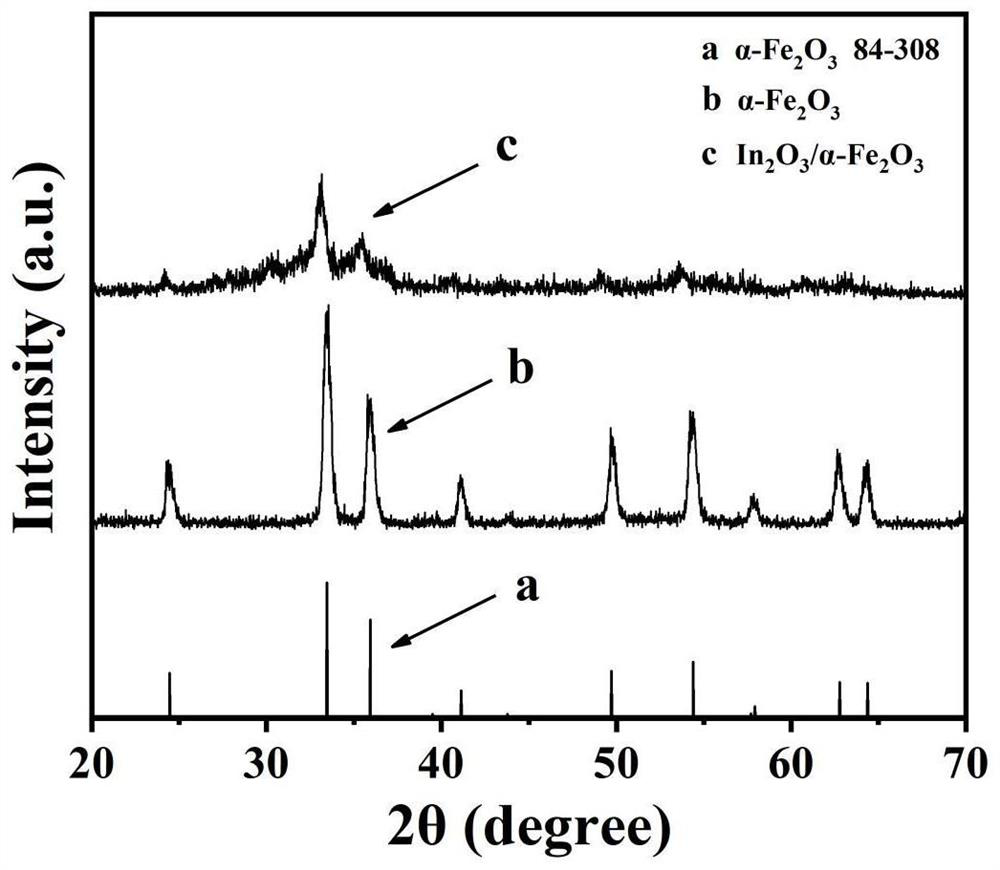

[0035] A. In 2 o 3 / α-Fe 2 o 3 Preparation method of nanowires:

[0036] a1: According to the mass ratio of 5 / 100 to 8 / 100, weigh ferric nitrate hydrate and N,N-dimethylformamide into a vessel, and then stir until the ferric nitrate is completely dissolved to obtain the first mixed solution;

[0037] a2: Based on the ferric nitrate hydrate in step a1, weigh the indium nitrate hydrate into the first mixed solution according to the molar ratio of 4:1, and stir at room temperature until the indium nitrate is completely dissolved to obtain the second mixed solution. liquid;

[0038] a3: Based on the N,N-dimethylformamide in step a1, according to the mass ratio of 10 / 100 to 20 / 100, weigh polyvinylpyrrolidone into the second mixed solution, and stir at room temperature, Finally obtain a reddish-brown viscous solution, which is recorded a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com