Etching solution, touch panel and manufacturing method of touch panel

A technology of a touch panel and a manufacturing method, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc., and can solve the problem of inability to meet the narrow frame requirements of the display, the inability to reduce the size of the lead wires in the peripheral area, and the size enlargement, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

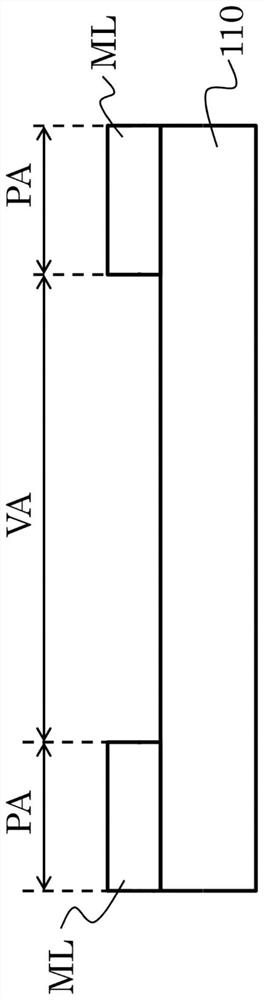

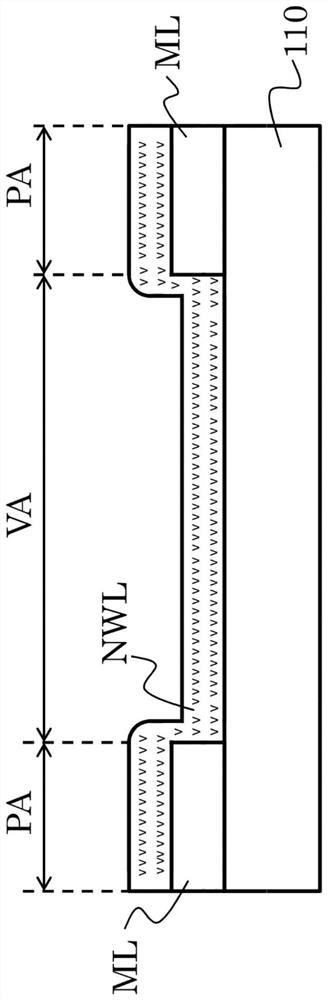

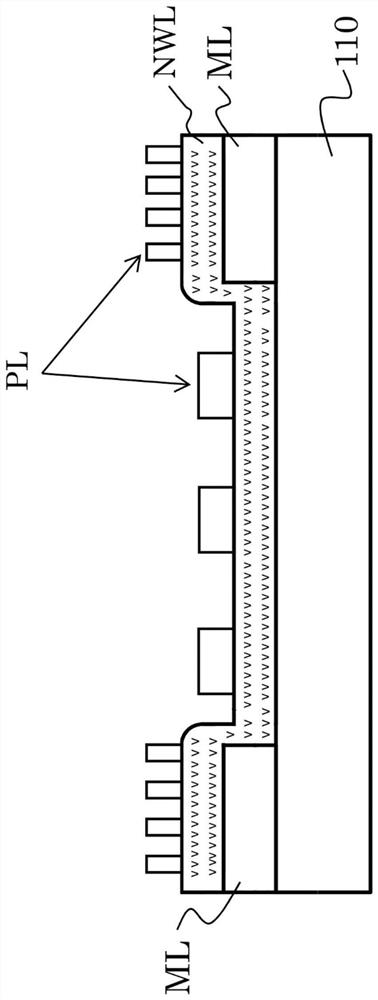

[0081] A number of embodiments of the present invention will be disclosed below with the accompanying drawings. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the present invention, these practical details are unnecessary. In addition, for the sake of simplification of the drawings, some conventional structures and components are simply shown in the drawings.

[0082] As used herein, "about", "approximately" or "approximately" generally means that the error or range of the value is within 20%, preferably within 10%, more preferably within Within five percent. If there is no explicit statement in the text, the numerical values mentioned are all regarded as approximate values, that is, there are errors or ranges indicated by "about", "approximately" or "approximately".

[0083] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com