A preparation method of a cathode material with high adsorption and catalytic performance for a lithium-sulfur battery

A technology of catalytic performance and positive electrode material, applied in battery electrodes, lithium storage batteries, positive electrodes, etc., can solve the problems of insufficiently improving the shuttle effect of polysulfides and weak physical interactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the positive electrode material with high adsorption and catalytic performance of the lithium-sulfur battery comprises the following steps:

[0027] (1) Preparation of silica sphere dispersion: adopt sol-gel method: add tetraethyl orthosilicate to the mixed solution of catalyst and alcohol solvent, and react to prepare nano-silica spheres;

[0028] (2) Preparation of highly uniform ethanol solution of phenolic resin: using aldehyde-phenol addition reaction: synthesized by phenol, formaldehyde and sodium hydroxide;

[0029] (3) Preparation of SiO 2 / AAO double template: put 1 piece of AAO template in 5mL of the silica sphere dispersion obtained in step (1), let it stand for 4 days, and then dry it naturally to obtain SiO 2 / AAO double template;

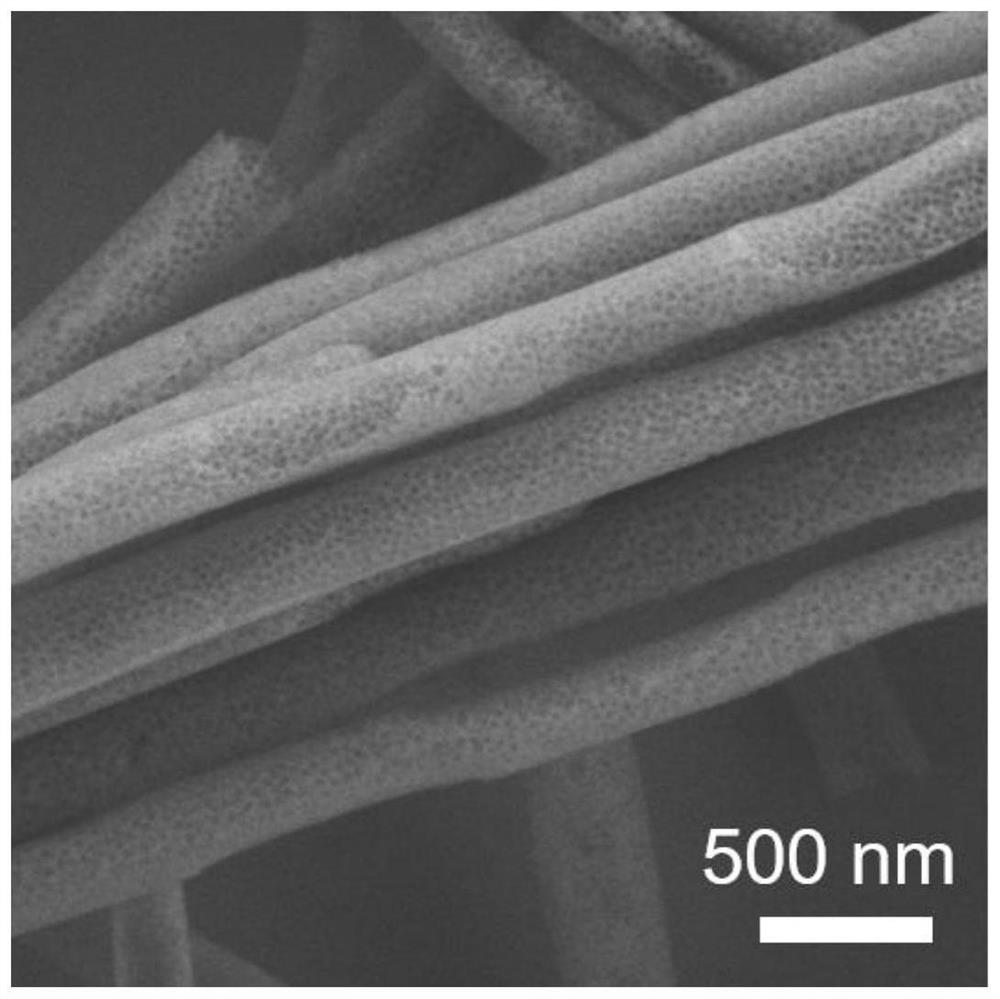

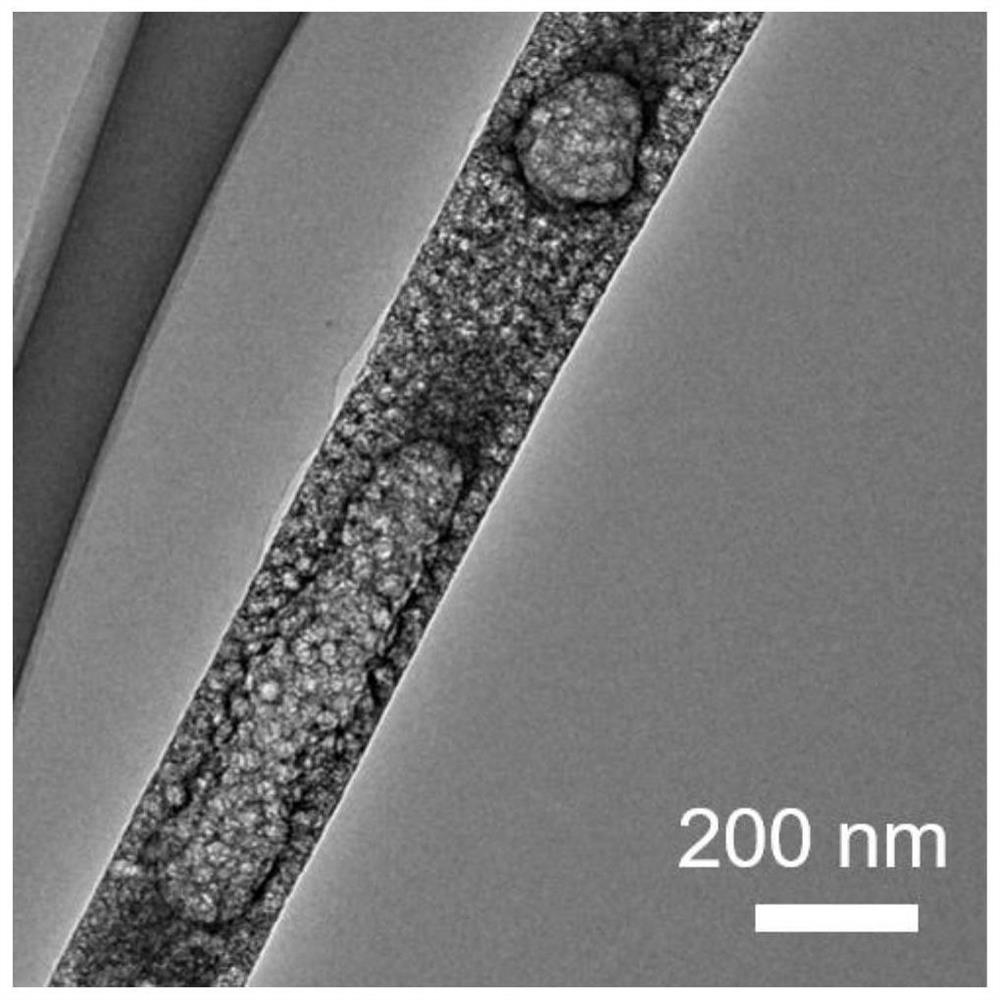

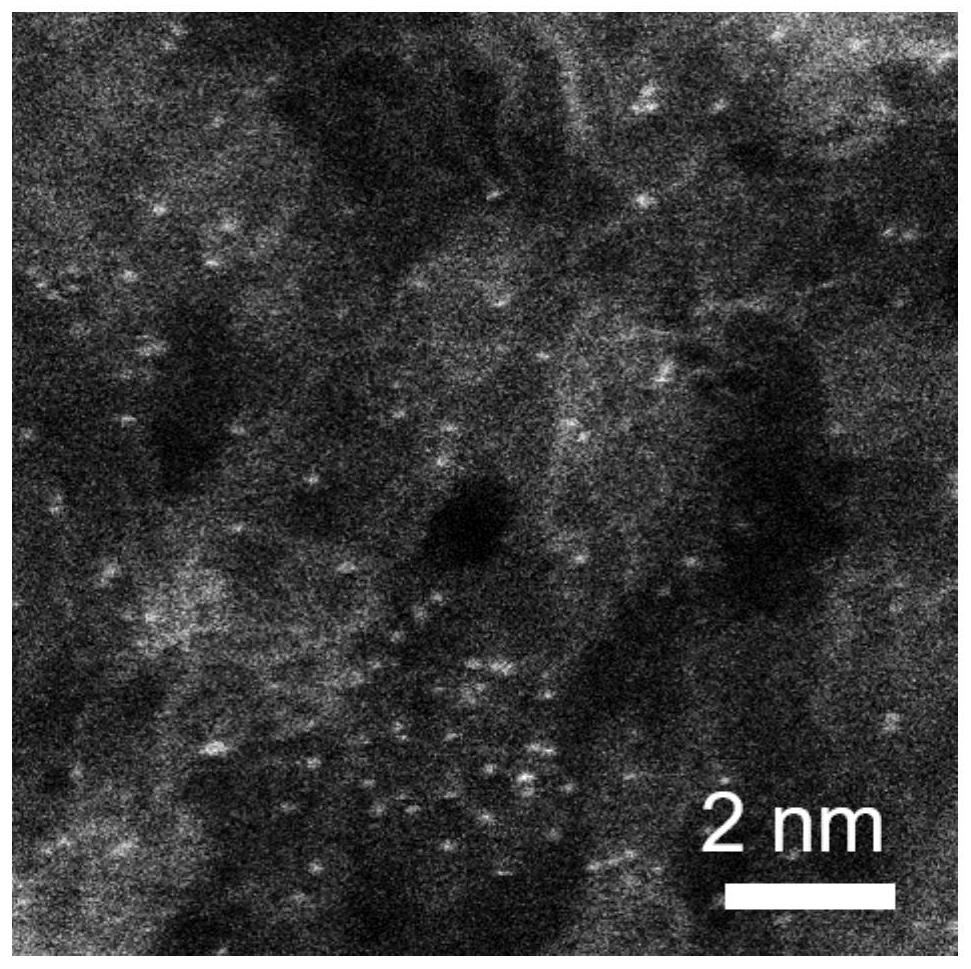

[0030] (4) Preparation of Ta / CNW: First, 100 μL of tantalum ethoxide, 500 μL of phenolic resin and 2 mL of absolute ethanol were sonicated to form a mixed solution, and then the SiO obtained in step (...

Embodiment 2

[0036] The preparation method of the positive electrode material with high adsorption and catalytic performance of the lithium-sulfur battery comprises the following steps:

[0037] (1) Preparation of silica sphere dispersion: adopt sol-gel method: add tetraethyl orthosilicate to the mixed solution of catalyst and alcohol solvent, and react to prepare nano-silica spheres;

[0038] (2) Preparation of highly uniform ethanol solution of phenolic resin: using aldehyde-phenol addition reaction: synthesized by phenol, formaldehyde and sodium hydroxide;

[0039] (3) Preparation of SiO 2 / AAO double template: put 1 piece of AAO template in 5mL of the silica sphere dispersion obtained in step (1), let it stand for 4 days, and then dry it naturally to obtain SiO 2 / AAO double template;

[0040] (4) Preparation of Ta / CNW: First, 50 μL of tantalum ethoxide, 200 μL of phenolic resin and 1 mL of absolute ethanol were ultrasonically formed into a mixed solution, and then the SiO obtained i...

Embodiment 3

[0043] The preparation method of the positive electrode material with high adsorption and catalytic performance of the lithium-sulfur battery comprises the following steps:

[0044] (1) Preparation of silica sphere dispersion: adopt sol-gel method: add tetraethyl orthosilicate to the mixed solution of catalyst and alcohol solvent, and react to prepare nano-silica spheres;

[0045] (2) Preparation of highly uniform ethanol solution of phenolic resin: using aldehyde-phenol addition reaction: synthesized by phenol, formaldehyde and sodium hydroxide;

[0046] (3) Preparation of SiO 2 / AAO double template: put 1 piece of AAO template in 5mL of the silica sphere dispersion obtained in step (1), let it stand for 4 days, and then dry it naturally to obtain SiO 2 / AAO double template;

[0047] (4) Preparation of Ta / CNW: First, 200 μL of tantalum ethoxide, 800 μL of phenolic resin and 3 mL of absolute ethanol were sonicated to form a mixed solution, and then the SiO obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com