Synthesis method of tunnel layered intergrowth phase sodium manganate serving as positive electrode material of sodium-ion battery

A technology of sodium ion battery and material sodium manganate, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the volume energy density of sodium ion batteries, difficult to mass-produce, poor cycle performance, etc., to improve the cycle performance. Effects of stability, alleviation of phase transition stress, and high charge-discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

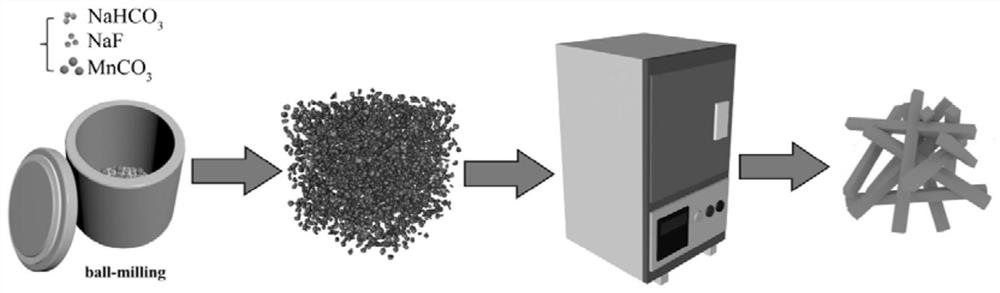

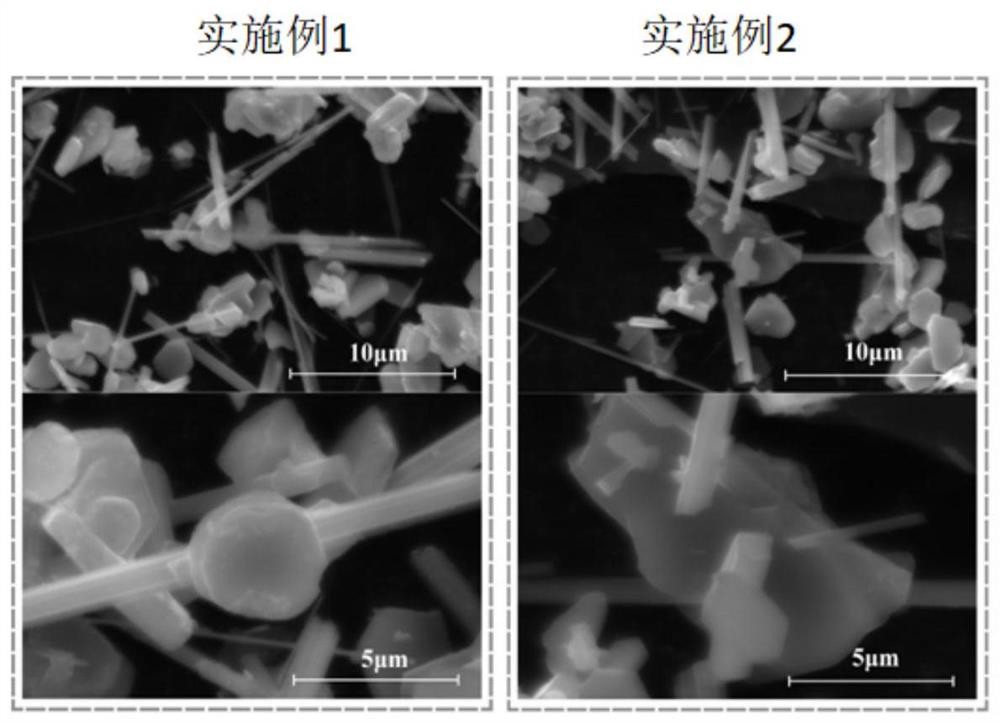

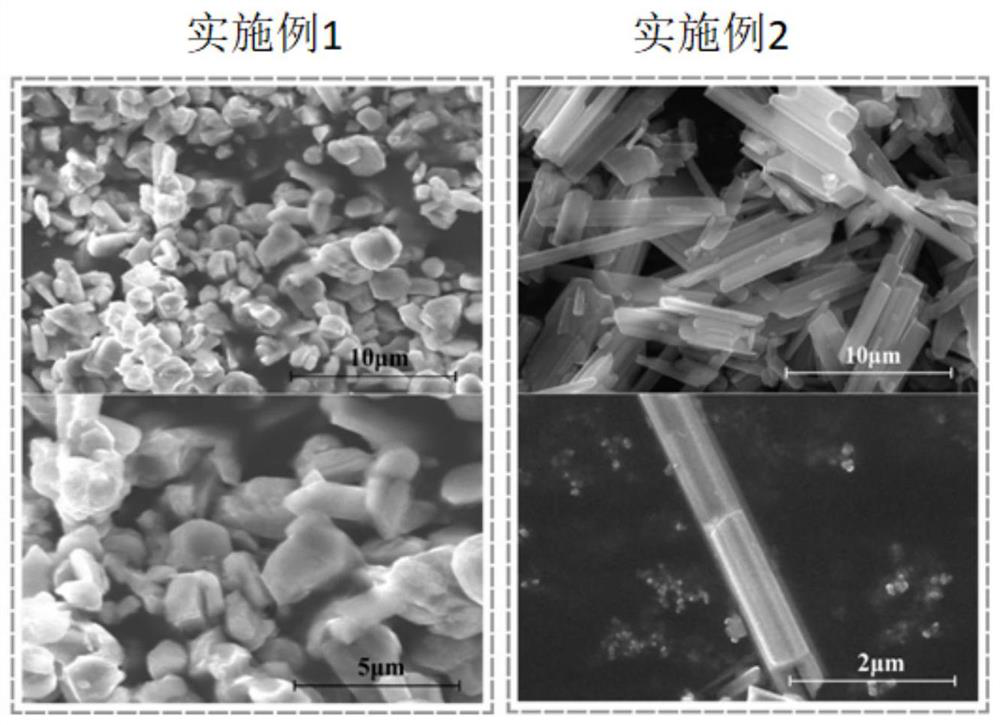

[0022] NaHCO 3 :NaF:MnCO 3 After weighing the raw materials according to the molar ratio of 4:1:10, put them into a ball mill jar and mill them in a planetary ball mill at a speed of 500 rpm for 12 hours to obtain a uniformly mixed precursor. The precursor obtained after ball milling was put into a corundum crucible, heated to 850°C in a muffle furnace at a heating rate of 2°C / min, and taken out after holding for 12 hours to obtain Na 0.5 MnO 2-x f x powder.

[0023] Na 0.5 MnO 2-x f x After the powder, the conductive agent (Super P) and the binder (PVDF) were ground uniformly according to the mass ratio of 8:1:1, an appropriate amount of N-methylpyrrolidone was added and stirred for 12 hours to obtain a uniform slurry. The slurry is coated on carbon-coated aluminum foil, and the coated wet film thickness is 100 μm, and then the coated aluminum foil is placed in a vacuum oven at 100 ° C for 24 hours to obtain the positive electrode sheet of the sodium ion battery, and p...

Embodiment 2

[0026] This embodiment is basically the same as embodiment 1, the only difference is the NaHCO in the precursor 3 :NaF:MnCO 3 The molar ratio is 1:1:4. NaHCO 3 :NaF:MnCO 3 After weighing the raw materials according to the molar ratio of 1:1:4, put them into a ball mill jar and mill them in a planetary ball mill at a speed of 500 rpm for 12 hours to obtain a uniformly mixed precursor. The precursor obtained after ball milling was put into a corundum crucible, heated to 850°C in a muffle furnace at a heating rate of 2°C / min, and taken out after holding for 12 hours to obtain Na 0.5 MnO 2-x f x powder.

[0027] Na 0.5 MnO 2-x f x The powder, the conductive agent (Super P) and the binder (PVDF) are ground evenly according to the mass ratio of 8:1:1, and an appropriate amount of N-methylpyrrolidone is added and stirred for 12 hours to obtain a uniform slurry. The material was coated on carbon-coated aluminum foil with a wet film thickness of 100 μm, and then the coated al...

Embodiment 3

[0034] This comparative example is basically the same as Example 1, the only difference is that NaHCO in the precursor 3 :MnCO 3 The molar ratio is 1:2. NaHCO 3 :MnCO 3 After weighing the raw materials according to the molar ratio of 1:2, put them into a ball mill jar and mill them in a planetary ball mill at a speed of 500 rpm for 12 hours to obtain a uniformly mixed precursor. The precursor obtained after ball milling was put into a corundum crucible, heated to 850°C in a muffle furnace at a heating rate of 2°C / min, and taken out after holding for 12 hours to obtain Na 0.5 MnO 2-x f x powder.

[0035] will get Na 0.5 MnO 2-x f x After the powder, the conductive agent (Super P) and the binder (PVDF) were ground uniformly according to the mass ratio of 8:1:1, an appropriate amount of N-methylpyrrolidone was added and stirred for 12 hours to obtain a uniform slurry. The slurry was coated on the carbon-coated aluminum foil with a wet film thickness of 100 μm, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com