Preparation method of lithium battery ceramic compensation diaphragm and lithium battery

A technology for preparing lithium batteries and thin films, which is applied to lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc. The effect of charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

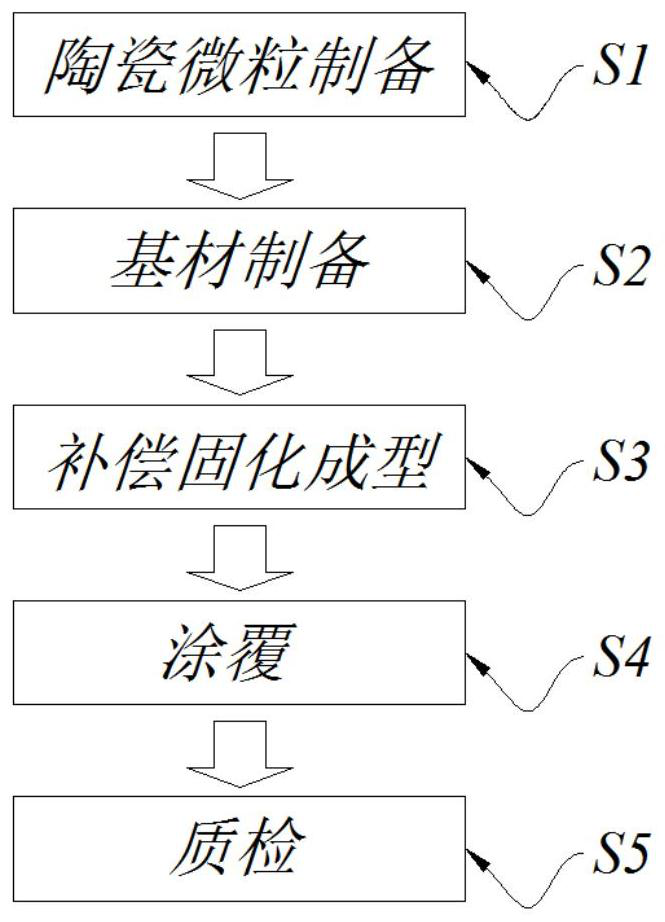

[0034] A preparation method of a lithium battery ceramic compensation diaphragm disclosed in an embodiment of the present invention comprises the following steps:

[0035] S1: Preparation of Ceramic Particles

[0036] The inorganic ceramic material is prepared into ceramic particles, and the maximum diameter of the ceramic particles is 0.05 micron.

[0037] Among them, the inorganic ceramic material is a new type of ceramic material, which can be a pure oxide ceramic. The new type of ceramic material has its unique advantages in performance, and has better high temperature resistance in terms of thermal and mechanical properties.

[0038] Specifically, the inorganic ceramic material is one or more of Al2O3, ZrO2, MgO, CaO, BeO, and ThO2, all of which are pure oxide ceramics.

[0039] S2: Substrate Preparation

[0040] The porous material is prepared as a crystalline polymer film, and the crystalline polymer film is prepared as a highly oriented multilayer structure.

[0041...

Embodiment 2

[0054] A preparation method of a lithium battery ceramic compensation diaphragm disclosed in an embodiment of the present invention comprises the following steps:

[0055] S1: Preparation of Ceramic Particles

[0056] The inorganic ceramic material is prepared into ceramic particles, and the maximum diameter of the ceramic particles is 0.22 microns.

[0057] Among them, the inorganic ceramic material is a new type of ceramic material, which can be a non-oxide ceramic. The new type of ceramic material has its unique advantages in performance, and has better high temperature resistance in terms of thermal and mechanical properties.

[0058] Specifically, the inorganic ceramic material is one or more of carbide, boride, nitride and silicide, all of which are non-oxide ceramics.

[0059] S2: Substrate Preparation

[0060] The porous material is prepared as a crystalline polymer film, and the crystalline polymer film is prepared as a highly oriented multilayer structure.

[0061...

Embodiment 3

[0074] A preparation method of a lithium battery ceramic compensation diaphragm disclosed in an embodiment of the present invention comprises the following steps:

[0075] S1: Preparation of Ceramic Particles

[0076] The inorganic ceramic material is prepared into ceramic particles, and the maximum diameter of the ceramic particles is 0.15 microns.

[0077] Among them, the inorganic ceramic material is a new type of ceramic material, which can be a non-oxide ceramic. The new type of ceramic material has its unique advantages in performance, and has better high temperature resistance in terms of thermal and mechanical properties.

[0078] The inorganic ceramic material is one or more of carbide, boride, nitride and silicide, all of which are non-oxide ceramics.

[0079] S2: Substrate Preparation

[0080] The porous material is prepared as a crystalline polymer film, and the crystalline polymer film is prepared as a highly oriented multilayer structure.

[0081] Wherein, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com