Preparation method of high-emulsibility coffee-grounds protein particles

A technology of coffee grounds and emulsification, which is applied in the field of application and protein modification, can solve the problem of low utilization rate of coffee grounds protein, and achieve the effect of saving experiment time, improving emulsification and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present embodiment provides a method for preparing high-emulsification coffee grounds protein particles, comprising the following steps:

[0028] Step 1: using coffee grounds as raw materials, using microwave combined wall breaking method to process and extract coffee grounds protein in coffee grounds;

[0029] Step 2: Using coffee grounds protein as a starting material, using a twin-screw extruder to stabilize and prepare coffee grounds protein particles.

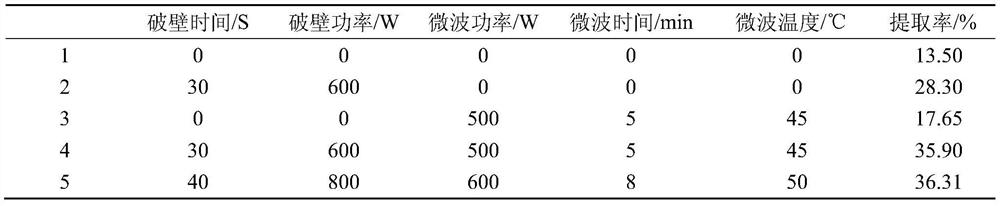

[0030] In step 1, the microwave combined wall-breaking method is used to extract the coffee grounds protein in the coffee grounds, and the specific conditions are as follows: the coffee grounds and water are mixed at a mass ratio of 1:10 for wall-breaking treatment, and then microwave-assisted to obtain a mixed solution , adjust the pH of the mixed solution to 10, and react in a water bath at 90 °C for 60 min, then centrifuge to get the supernatant, adjust the pH of the supernatant to 4.5, and then centrifuge to...

Embodiment 1

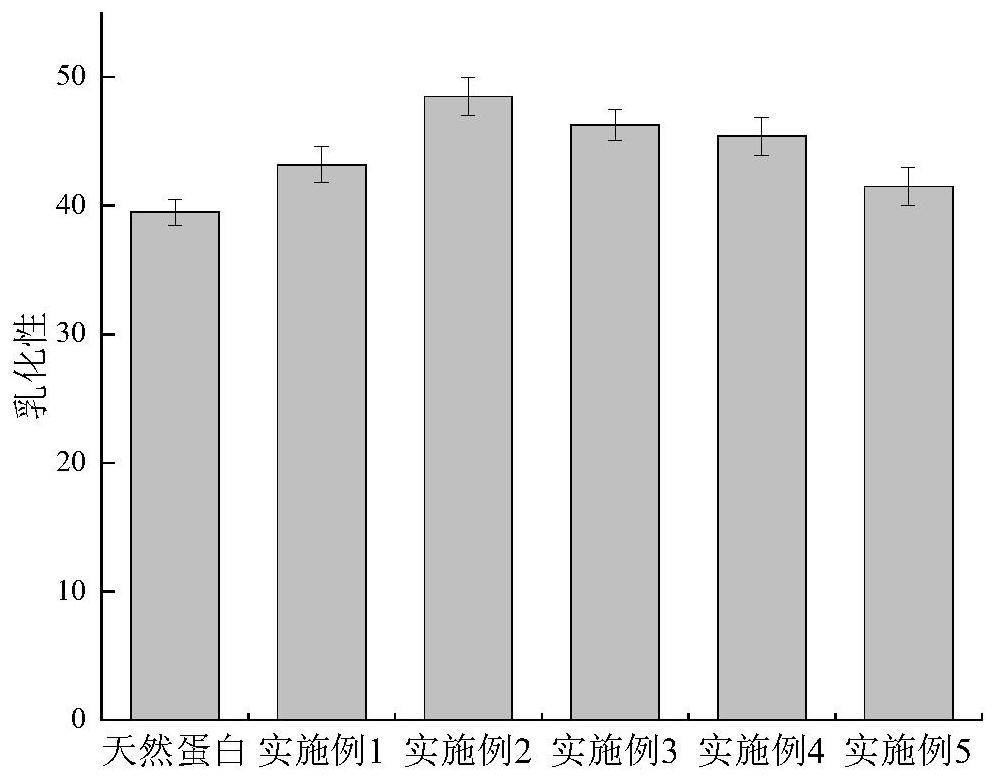

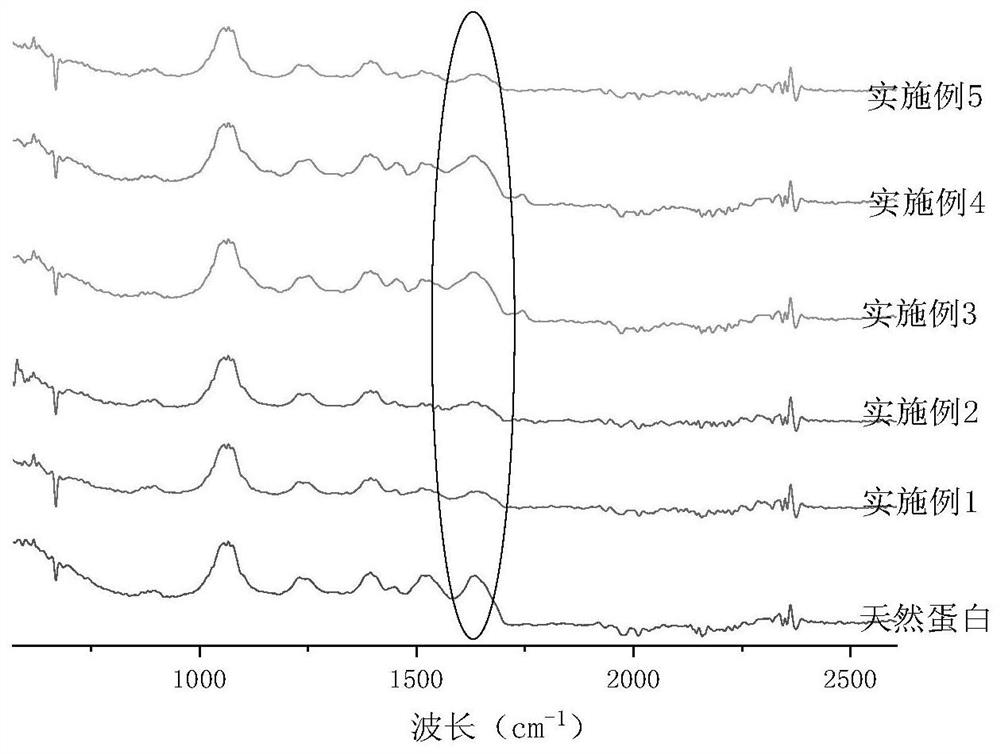

[0045]Using coffee grounds as raw material, microwave combined with wall-breaking method to extract coffee grounds protein in coffee grounds, mix coffee grounds and water in a mass ratio of 1:10 for wall-breaking treatment, and then assisted by microwave; adjust pH to 10, 90℃ After the water bath reaction for 60 min, the supernatant was collected by centrifugation, the pH was adjusted to 4.5, and the precipitate was collected by centrifugation. The pH was adjusted to 7 and dried at low temperature to prepare coffee grounds protein. Set the water feeding speed to 13kg / h, the feeding speed to 6kg / h, and control the moisture content of the material in the machine to be 40%; set the temperature of the high temperature section to 50°C, from the feeding zone to the forming zone through five-zone dark box operations, The samples were extruded, dried in a vacuum drying oven, and pulverized through a 150-mesh sieve to prepare coffee grounds protein particles. Infrared results can be se...

Embodiment 2

[0047] In the invention, coffee grounds are used as raw materials, and the coffee grounds protein in the coffee grounds is extracted by microwave combined with a wall-breaking method. After reacting in a water bath at 90°C for 60 min, centrifuge to take the supernatant, adjust the pH to 4.5 and centrifuge to take the precipitate, adjust the pH to 7 and dry at low temperature to prepare coffee grounds protein. Set the water feeding speed to 13kg / h and the feeding speed to 6kg / h, and control the moisture content of the material in the machine to be 50%; set the temperature of the high temperature section to 50°C, from the feeding zone to the forming zone through the five-zone dark box operation, The sample was extruded, dried in a vacuum drying oven, and crushed through a 150-mesh sieve to prepare coffee grounds protein particles. The infrared results can be seen, 1519.84cm -1 The peak disappeared completely and turned into dense small peaks. In this interval, the frequency of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com