Buffering and transferring device for machine tool assembly line finish machining of spindle parts

A transfer device and parts technology, applied in the direction of tool storage devices, manufacturing tools, conveyor objects, etc., can solve the problems of affecting accuracy, low processing efficiency, discrete processing procedures, etc., to improve the level of intelligence, improve production efficiency, improve The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

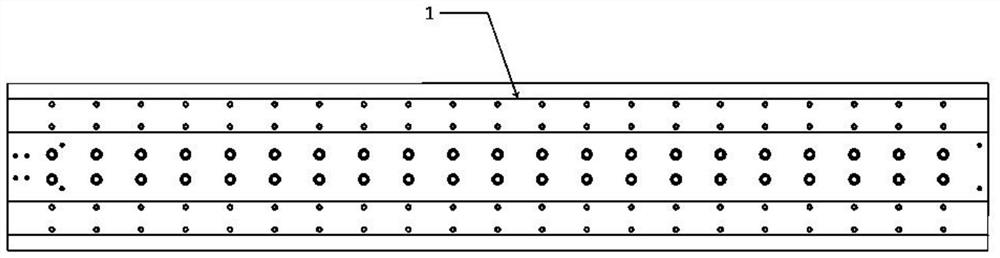

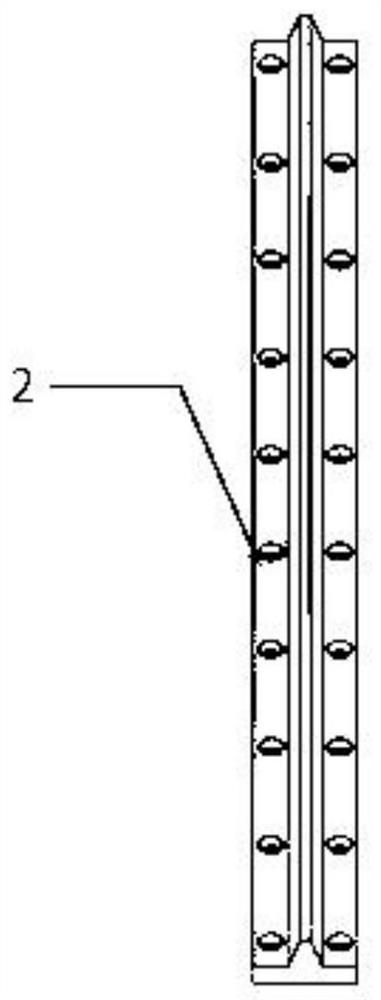

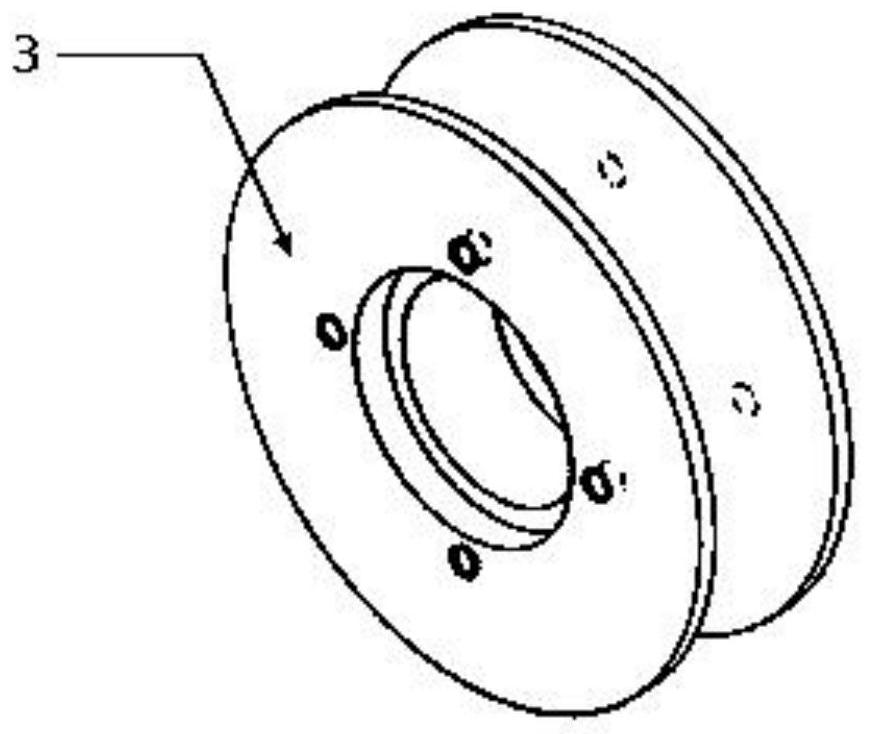

[0044] See Figure 1-16 , a cache transfer device invented by the assembly line processing of spindle parts includes: base plate 1, guide rail 2, roller 3, roller shaft 4, bearing 5, bearing end cover 6, motor bracket 7, servo motor 8, coupling 9 , lead screw 10, bearing with seat 11, bearing seat bracket 12, screw nut seat 13, mobile bracket 14, cylinder 15, guide rod 16, bracket 17, robot 18, magnetic suction picker 19, binocular camera 20 , guide rail 21, pad 22, cylinder support 23, cylinder, support plate 25, dividing plate 26, binocular camera support 27 and auxiliary electrical control system.

[0045] In the above solution, the base plate 1 is placed at a suitable position on the machine tool production line and fixed with bolts, the guide rail is placed in the guide rail groove of the base plate, the roller is placed on the guide rail, and the roller shaft is connected to the roller through a bearing. The moving bracket is connected to the roller shaft, the bearing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com