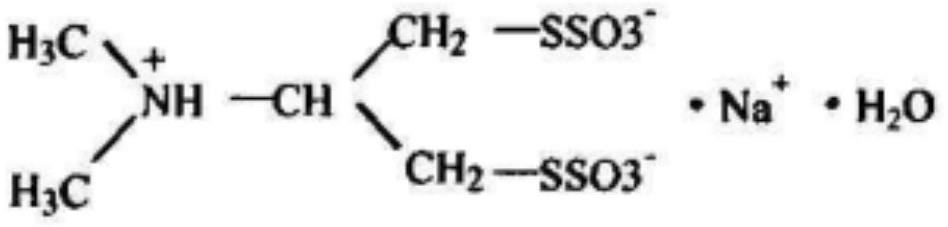

Water-saving high-purity monosultap synthesis process

A synthesis process and a technology for insecticidal single, applied in the field of water-saving and high-purity insecticidal single synthesis process, can solve the problems of low purity, large amount of waste water, foul odor in production environment, etc., to improve the reaction yield, promote the complete reaction, Environmentally efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

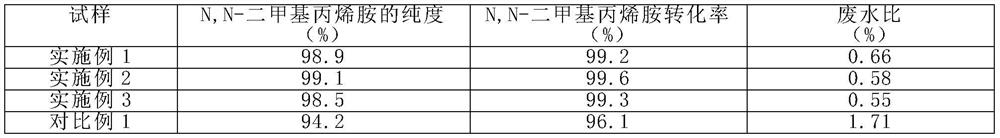

Embodiment 1

[0049] A kind of water-saving high-purity insecticidal single synthesis technique, described technique is specifically as follows:

[0050] (1) Amination reaction

[0051] (1) Open the amination reaction kettle to cool the brine, and the temperature of the cooling kettle is 0°C;

[0052] (2) Open the reflux condenser on the amination reactor, and drop into the concentrated dimethylaminopyridine solution;

[0053] (3) Stirring is started, and allyl chloride is added dropwise evenly, and pyridine is added dropwise simultaneously, and dimethylamine is maintained when the dropwise addition is completed: allyl chloride: the mol ratio of pyridine is 1:1:1;

[0054] (4) After the reaction, add water with 1 / 3 of the total molar weight of pyridine, stir for 10 min, and then let stand to separate layers;

[0055] (5) Stand and stratify for 30 minutes, separate the waste water layer in the lower layer, and the upper layer is N,N-dimethylacrylamine;

[0056] (6) Repeat the above steps ...

Embodiment 2

[0075] A kind of water-saving high-purity insecticidal single synthesis technique, described technique is specifically as follows:

[0076] (1) Amination reaction

[0077] (1) Open the amination reaction kettle to cool the brine, and the temperature of the cooling kettle is -2°C;

[0078] (2) Open the reflux condenser on the amination reactor, and drop into the concentrated dimethylaminopyridine solution;

[0079] (3) Stirring is started, and allyl chloride is added dropwise evenly, and pyridine is added dropwise simultaneously, and dimethylamine is maintained when the dropwise addition is completed: allyl chloride: the mol ratio of pyridine is 1:1:1;

[0080] (4) After the reaction, add water with 1 / 4 of the total molar weight of pyridine, stir for 15 min, and then let stand to separate layers;

[0081] (5) Stand and stratify for 30 minutes, separate the waste water layer in the lower layer, and the upper layer is N,N-dimethylacrylamine;

[0082] (6) Repeat the above steps...

Embodiment 3

[0101] A kind of water-saving high-purity insecticidal single synthesis technique, described technique is specifically as follows:

[0102] (1) Amination reaction

[0103] (1) Open the amination reaction kettle to cool the brine, and the temperature of the cooling kettle is -2°C;

[0104] (2) Open the reflux condenser on the amination reactor, and drop into the concentrated dimethylaminopyridine solution;

[0105] (3) Stirring is started, and allyl chloride is added dropwise evenly, and pyridine is added dropwise simultaneously, and dimethylamine is maintained when the dropwise addition is completed: allyl chloride: the mol ratio of pyridine is 1:1:1;

[0106] (4) After the reaction, add water with 1 / 4 of the total molar weight of pyridine, stir for 20min, and then leave to stand for layering;

[0107] (5) Stand and stratify for 40 minutes, separate the waste water layer in the lower layer, and the upper layer is N,N-dimethylacrylamine;

[0108] (6) Repeat the above steps (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com